82

83

Since the front wheel of the e-muli, like all cargo bikes of the so-called Long

John style, is not directly under the handlebars but in front of the load surface,

the steering movement must be transferred from the handlebars to the front

wheel. The steering linkage translates the steering movement of the handlebar to

the front wheel. It is connected to the boom on the steering tube and the boom

on the fork vi ball joint and swivel joint.

Lane setting

The toe of the front wheel is also set vi the steering linkage. The lane is set

correctly at the factory. If the lane should become misaligned over time, rst try

correcting the lane setting by slightly adjusting the handlebars by loosening the

stem bolts and bringing the handlebars and front wheel back into alignment. The

handlebar bar must be in perpendicular position to the frame and the front

wheel in line with the frame.

However, such correction by adjusting the handlebar is only possible with

small toe adjustment, because the cantilever on the steering tube and the hand-

lebar bracket should be largely in line. In the case of large toe adjustment, it is

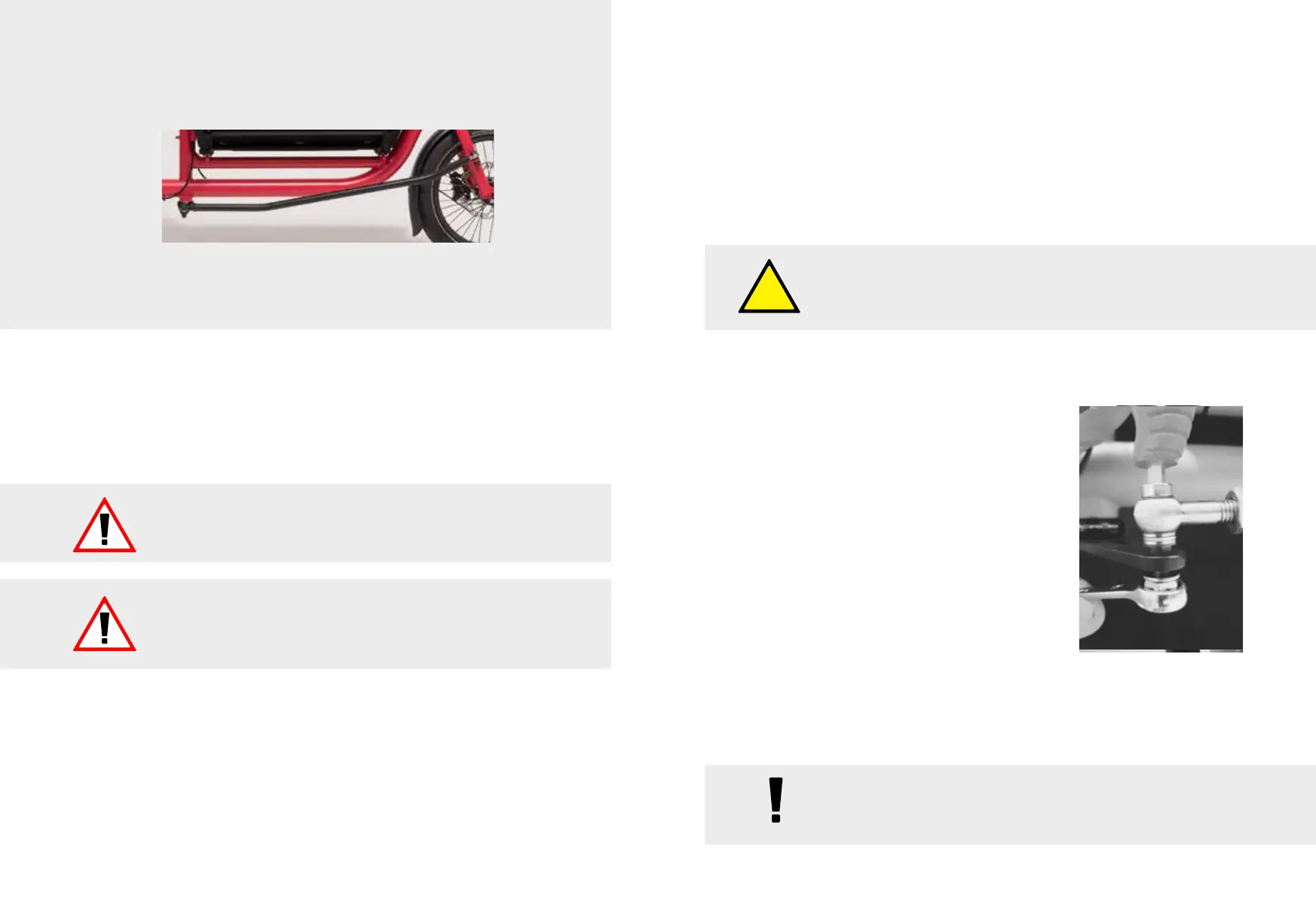

necessary to correct the toe directly at the steering linkage. To do this, the lock

nuts of the joints on the steering linkage must be loosened and the joint screws

screwed in or out accordingly. Note that the lock nuts are glued in place with

liquid threadlocker from the factory. So when you open and retighten the nuts,

apply appropriate threadlocker as well.

Note that the lock nuts on the steering linkage are glued in

place with liquid threadlocker from the factory. So when you

open and retighten the nuts, apply appropriate threadlocker

as well.

Steering resistance

The steering resistance can also be adjusted on

the steering linkage. To do this, loosen the screw

that attaches the linkage to the steering tube arm

slightly or tighten it accordingly.

If you prefer more sti steering, tighten the

screw little more. Keep in mind that strong

contact pressure also increases the wear of the

plastic plain bearings. If you prefer smoother

steering, tighten the screw less. Overall, however,

make sure that the screw is neither too tight nor

too loose. Too much contact pressure will jeo-

pardize safe steering in trac. On the one hand,

too loose an adjustment can cause the steering

linkage to rattle, swing open and make safe driving

impossible. On the other hand, too little contact pressure can cause the nut to

loosen completely while driving and the steering linkage to fall o, which can

result in serious falls.

Check the bolts and nuts on the steering linkage before

each ride. Loosening these connections while driving can

lead to serious falls and life-threatening injuries.

Attention! The steering linkage is highly safety-relevant

component. If the steering rod rattles or wobbles, do not

continue your ride.

The plastic plain bearings on the steering rod bolting wear

out and must be replaced when worn.

Steering linkage

Loading...

Loading...