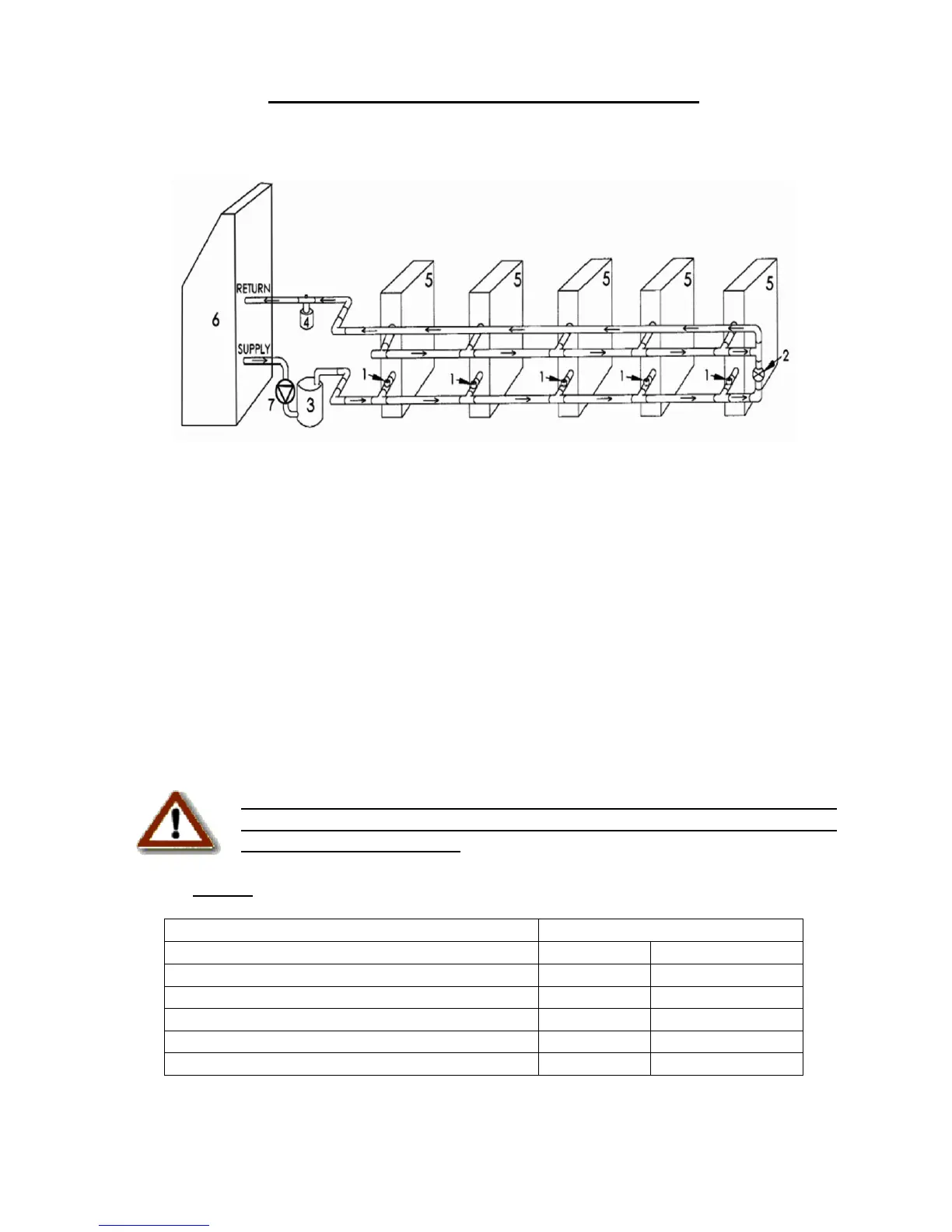

Composite Piping Layout and Design

Understanding the function and friction loss of each part of the piping system is important to

the layout and successful installation of a chilled liquid solution system.

1– 2 Way Liquid Solution Control Valve

2– Bypass Valve

3– Storage Tank

4– Expansion Tank

5– Fan Coil Unit

6– Chiller

7– Pump

The circulation pump is the key performer in the piping system. The pump must circulate the

liquid solution through the heat exchanger and piping system to the air handlers. Pumps are

designed to deliver a flow rate measured in gallons per minute (GPM). The pump must be

able to overcome the resistance to flow (pressure drop) imposed by the chiller components,

piping system, and air handlers while maintaining the necessary flow rates in gallons per

minute. Pump capacities in gallons per minute and pressure drop (feet of head) are listed in

Table 1.

An adjustable valve or balancing valve must be used to throttle the

discharge liquid solution flow rate to appropriate levels based on capacity

and glycol mix percentages.

Table 1 Chiller System Data

Min. Liquid Solution Flow Rate

Max. Liquid Solution Flow Rate

Min. Total Liquid Solution Content of System

Internal Chiller Pressure Loss

Chiller Liquid Solution Content

Piping resistance or pressure drop is measured in feet of head. A foot of head is the amount of

pressure drop imposed in lifting liquid solution one foot.

Page 13 of 28

Loading...

Loading...