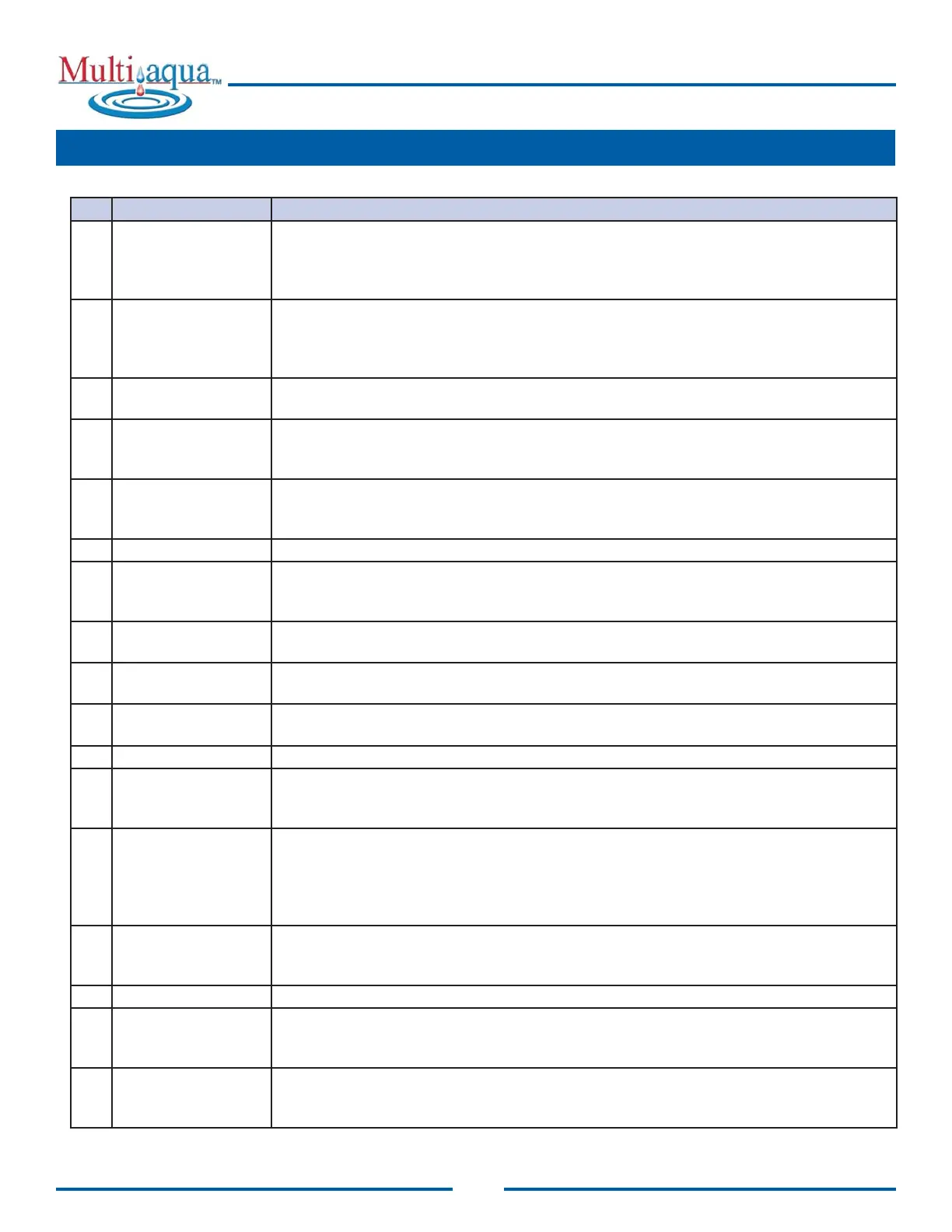

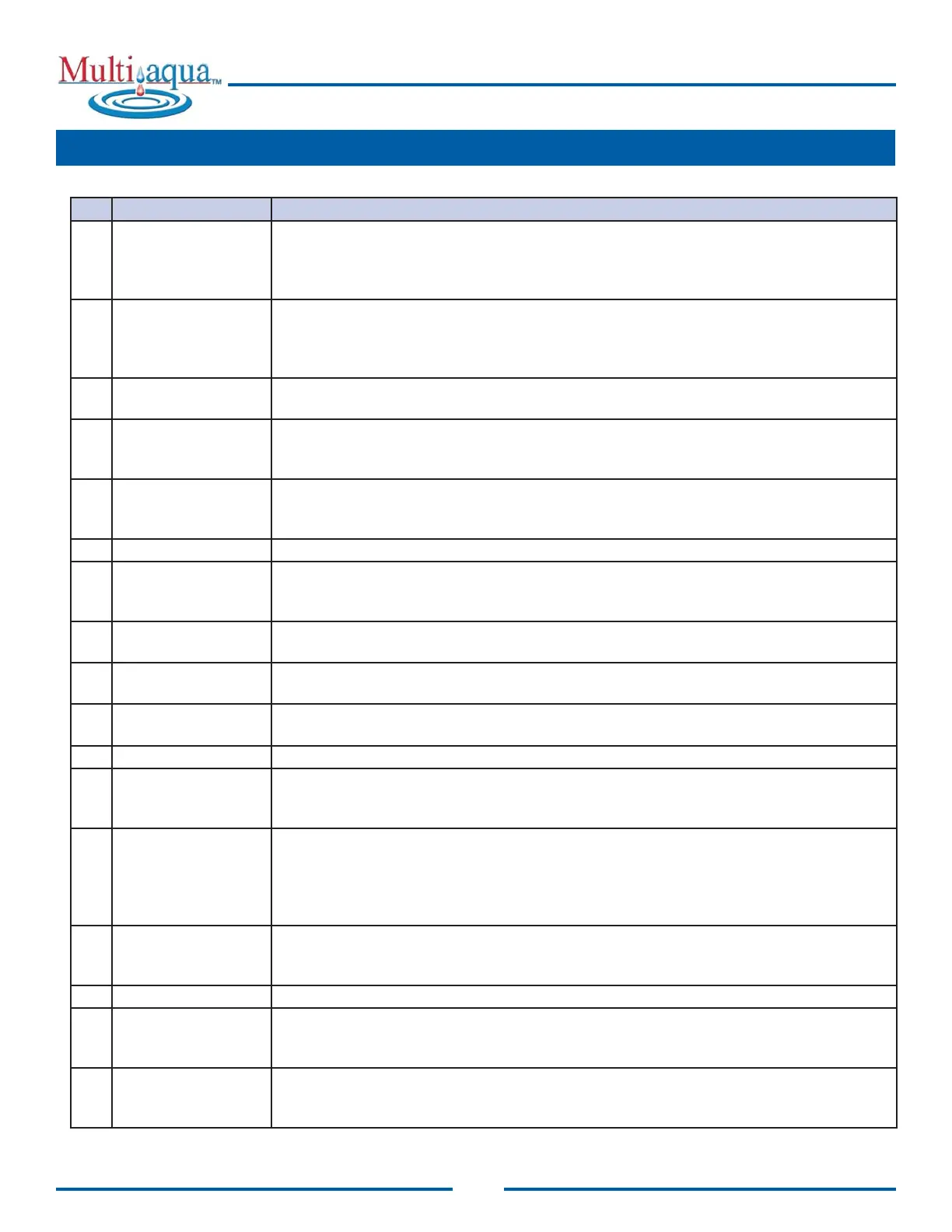

31

20. MHRC MAGNUM Setpoints

# Name Description

1 Cold Tank Targ Cold Tank Target. This value is used as the base to develop the Control Zone. The control target

is used with the control zone and rate of change of the controlling sensor to determine required

action for the Magnum. The ± control zone values are in the High and Low Zone areas of the set

point.

2 Hot Tank Targ Hot Tank Target. This value is used as the base to develop the Control Zone. The control target

is used with the control zone and rate of change of the controlling sensor to determine required

action for the Magnum. The ± control zone values are in the High and Low Zone areas of the set

point.

9 SPRHT TARGET EXV control is based upon superheat, this is the Superheat target that the Magnum will control to.

10 SPRHT ZONE ± The value in this Setpoint is added and subtracted to Setpoint #9 to determine the upper and lower

limits of the control zone respectively.

11 EXV LOAD ADJ The adjustment that will be made to the EXV percentage when the circuit changes to the Loading

state, or the closing adjustment that will be made when the circuit changes to the Unloading state.

Note: In MOP hold state, only closing adjustments are allowed.

12 EXV FINE ADJ The adjustment is made when in the 1

st

zone above or below the control zone.

13 EXV COURSE This adjustment is made when in the 2

nd

zone above or below the control zone and the

adjustments are made in 1/2 the time. When above or below the 2

nd

control zone the adjustments

are made in 1/4 the time.

15 EXV MIN % This is the minimum position of the EXV Valve when running. This value should be set to

accommodate for hot gas if available.

16 EXV MAX % This is the maximum position allowed when opening the valve. This value should be the valve %

opening at full capacity plus a 10 to 15 % margin.

17 LO SUPERHEAT If the calculated superheat remains below this value for the time specifi ed, the Magnum will

generate a LOW SUPERHEAT alarm.

18 LOWSUCTPSI DLY Delay in seconds when in ‘Low Suction PSI Opening’ between adjustments to the EXV valve.

19 EXV DELAY Delay in seconds between valve adjustments. Should not be less than 48. (When adjusting at

4x rate this will allow 12 seconds for the controller to process the results of the last action before

making the next changes.

20 EXV STRT TIME This is the time in seconds to hold the valve at the starting % Setpoint when the compressor starts.

Since the superheat calculation is not valid when the compressor is not running the EXV logic sets

the valve to a given position for a set time to allow the system to develop a valid superheat. The

Time In Seconds fi eld if set to zero then there is no delay. If non-zero this is the time delay that

allows the EXV to open before the compressor starts.

22 LOW AMBIENT If the ambient temperature is below this value the system will be disabled and the unit state will

be AMBIENT OFF. The unit will remain off until the ambient temperature rises above this Setpoint

value by 5.0F (2.5C).

23 POWERUP DELAY The time in seconds the system will remain in power up to allow stable power.

25 STEP SENSTIY This value is used to adjust the rate of response to changes in the control algorithm. 1 is the

fastest response, whereas higher numbers will mean a more gradual response. Used only with the

Magnum Control Zone control method.

26 STEP DELAY Value: This is the integration delay before making adjustments to the system capacity. Used only

with the Magnum Control Zone control method. If a value is placed in the time fi eld it will force a

minimum time between compressor starts.

Loading...

Loading...