!

!

!

!

!

!

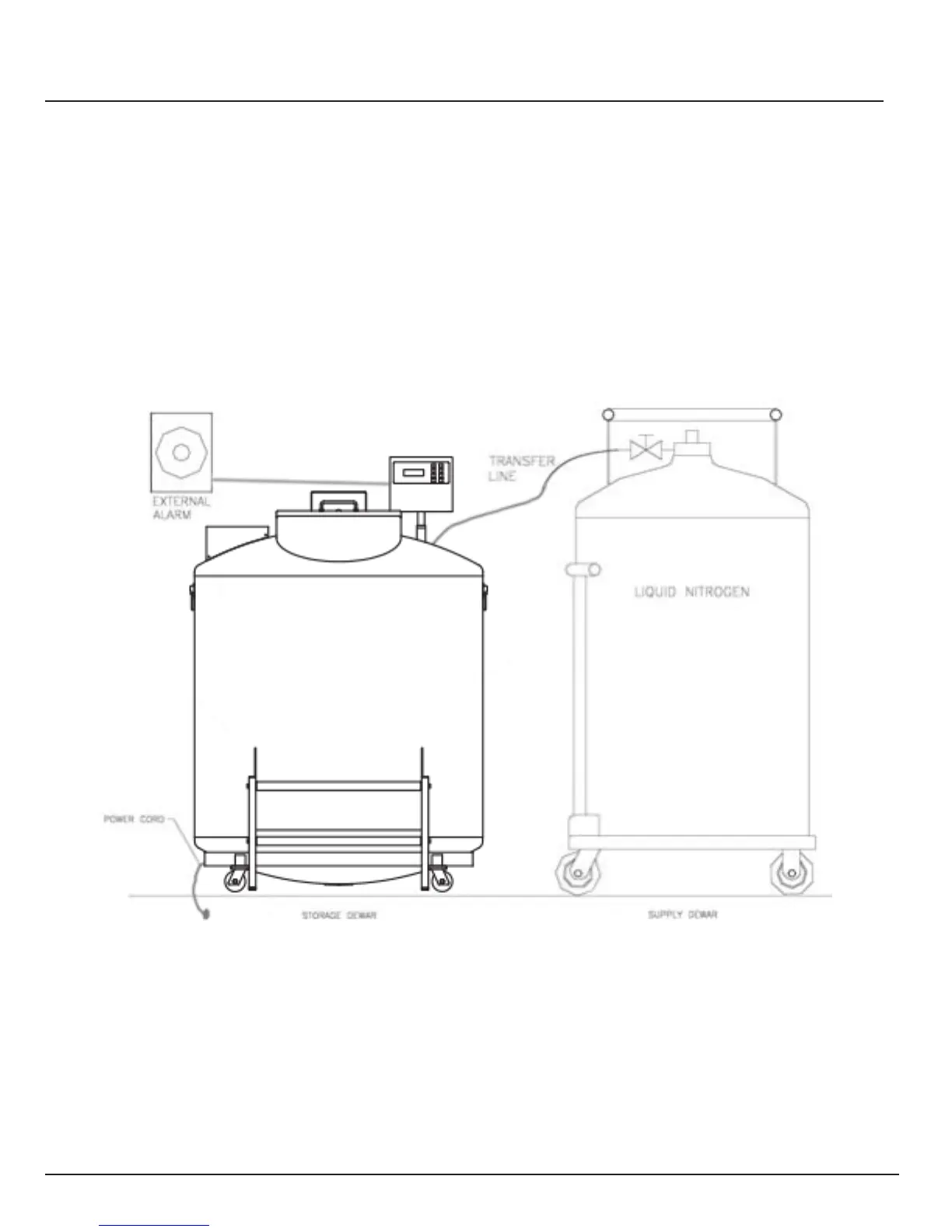

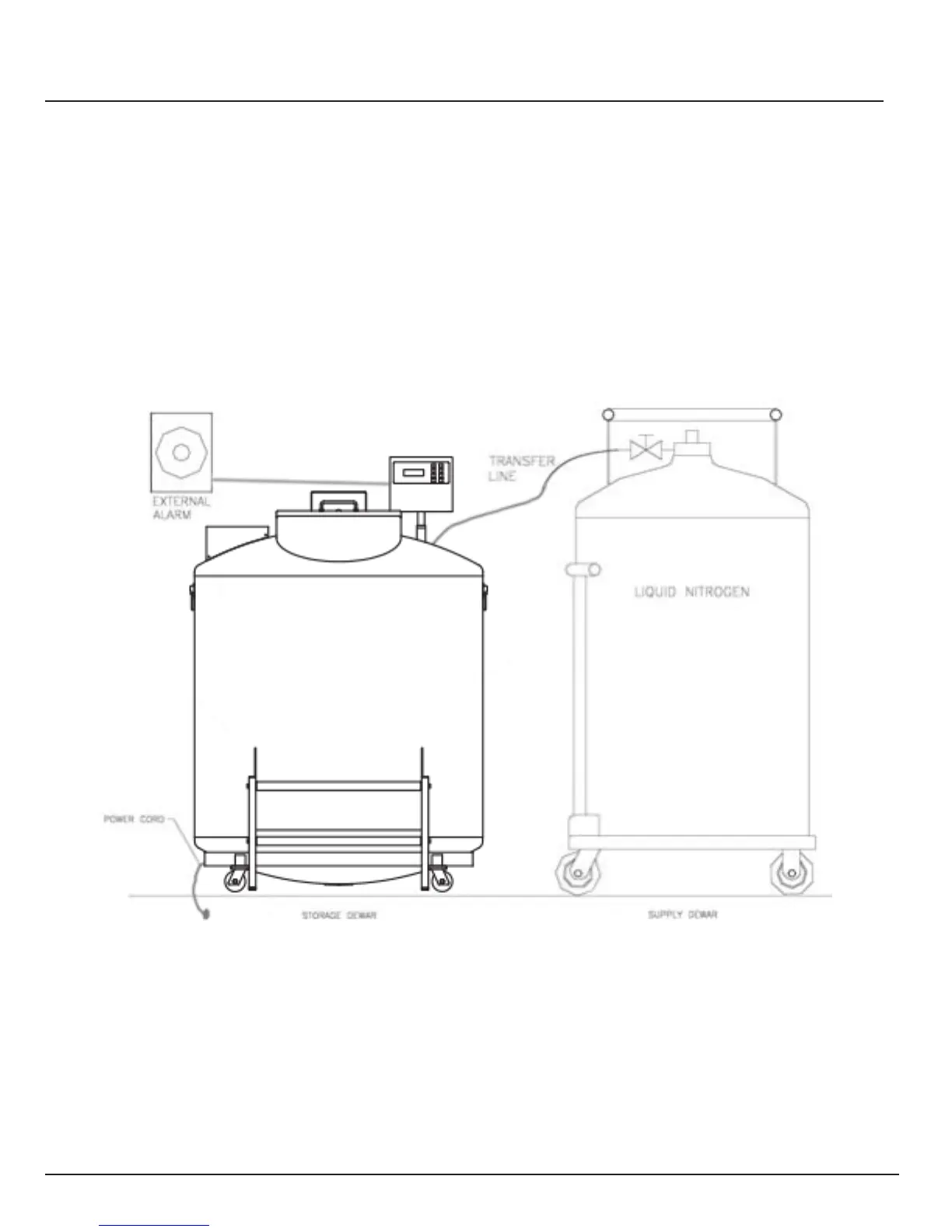

Connect a transfer line (included with freezer) from an LN

2

supply tank to the fill connection at the rear of the freezer.

Optimum supply tank pressure is 22 to 35 psi (1.5 to 2.4 bar). Although the plumbing assembly has a 50 psi (3.45 bar) pres-

sure relief device, it is recommended that the supply tank be pressurized below 35 psi (2.4 bar) to reduce the LN

2

“flash-off”

rate during filling and to maximize the cryogenic valve life. The supply line can be insulated to minimize LN

2

transfer loss-

es. After the transfer hose is securely coupled to the freezer and supply tank, ensure all connections are leak free by opening

the valve of the LN

2

supply tank and apply a soap and water solution to each field joint. You should not see bubbles

forming

at

any joint. Wipe away excess soap and water when finished. Before removing the transfer hose, ensure the LN

2

supply tank

valve is closed. Slowly and carefully loosen the transfer hose connection to vent any remaining pressure in the line before

disconnecting the hose.

!

!

!

Loading...

Loading...