2200LZJE-HO-C6-N_2013.12.

Chapter 7 Related Documents

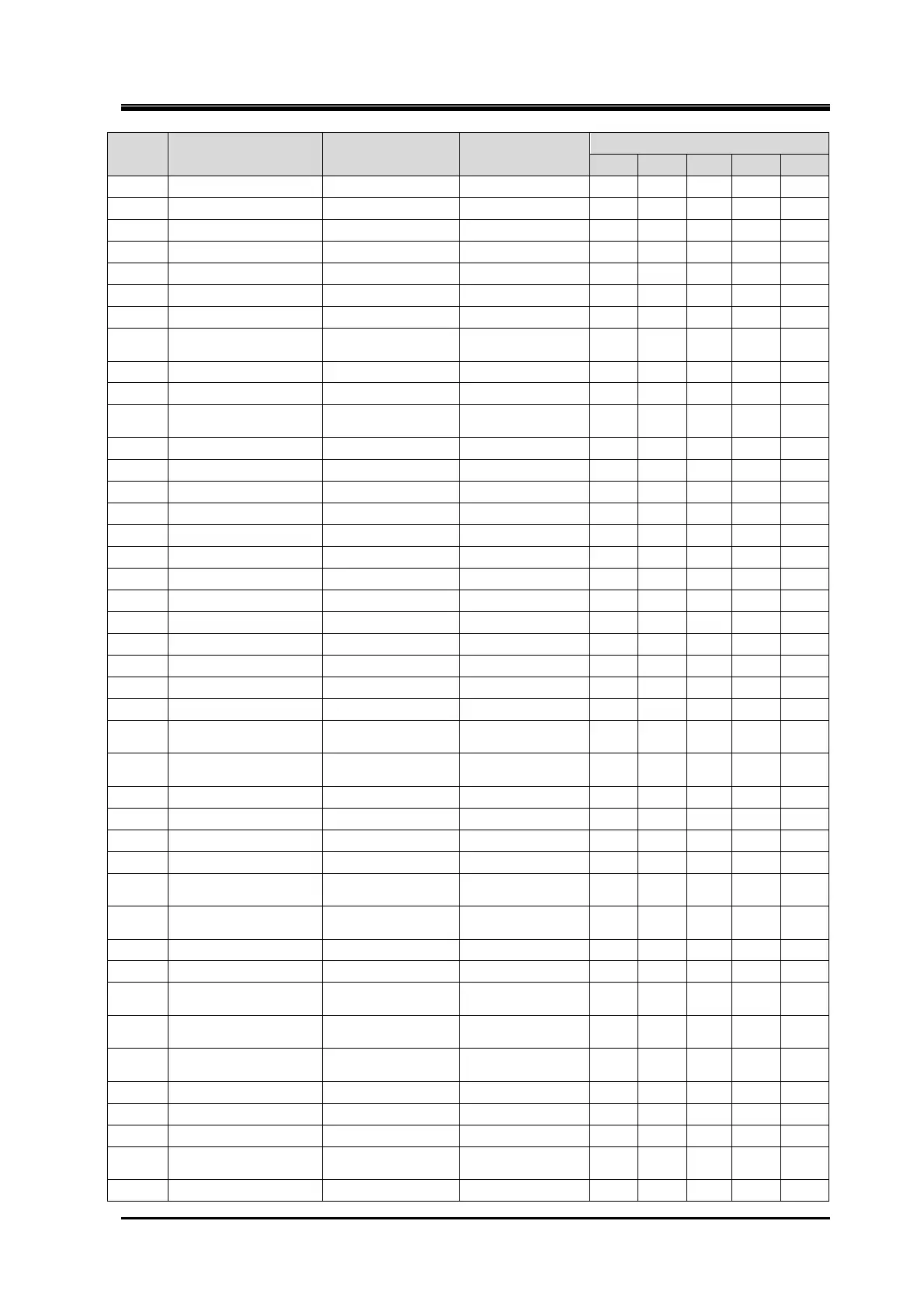

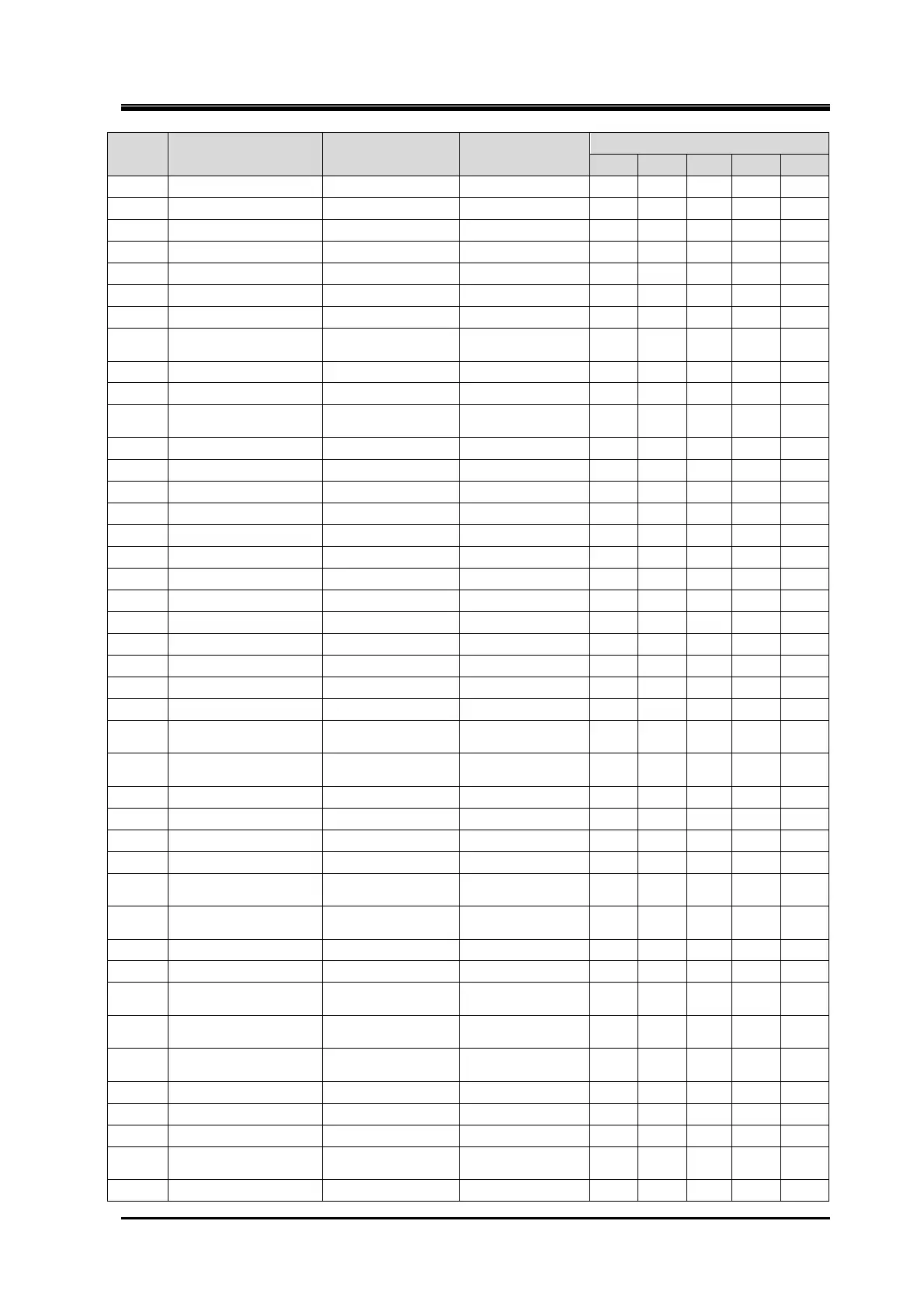

Compound 2-stage Screw Compressor 2016**C 7.2 Development Views, Assembly Sectional Views, and Parts Configuration Tables

7-17

No. Part name Code No. Remarks

Q’ty.

LLC LMC LSC MSC SSC

77-1 Indicator CAM (1) CS07700-2016SSC 2016SSC - - - - 1

77-2 Indicator CAM (2) CS07700-160L 160L** 1 - - - -

77-2 Indicator CAM (2) CS07700-160M 160M** - 1 - - -

77-2 Indicator CAM (2) CS07700-160S 160S** - - 1 1 1

78 Ball Bearing CS07800-200 #6000 2 2 2 2 2

79 Stop Ring NG12-010 S10 2 2 2 2 2

80 Bearing Gland CS08000-200 200*** 2 2 2 2 2

81

Hexagon Socket Head

Cap Screw

NB35406-015 M6×15 6 6 6 6 6

82 V-ring CS08200-200B 20×10×12 2 2 2 2 2

83 Spring CS08300-200 200*** 2 2 2 2 2

84

Retainer, Indicator

Cam Spring

CS08400-200 200*** 2 2 2 2 2

85 Oil Injection Pipe CS08500-200LUK 200LU* 1 1 1 - -

85 Oil Injection Pipe CS08500-2016MSC 2016MSC - - - 1 -

85 Oil Injection Pipe CS08500-2016SSK 2016SSC - - - - 1

86 O-ring PA11-021 JISB2401 1A P21 1 1 1 1 1

87-1 Guide Block (1) CS08700-200 200*** 1 1 1 1 1

87-2 Guide Block (2) CS08700-160 160*** 1 1 1 1 1

88-1 Stem, Guide Block (1) 200&250*** 1 1 1 1 1

88-2 Stem, Guide Block (2) 160*** 1 1 1 1 1

89-1 O-ring PA11-020 JISB2401 1A P20 2 2 2 2 2

89-2 O-ring PA11-016 JISB2401 1A P16 2 2 2 2 2

91 Shaft key (1) CS09100-200 200*** 1 1 1 1 1

92-1 Suction Flange (1) CS71300-150 JIS20K 150A(6") 1 1 1 1 1

92-2 Suction Flange (2) CS71300-100 JIS20K 100A(4") 1 1 1 1 1

93-1

Gasket, Suction

Flange (1)

CS71200-150N JIS20K 150A(6") 1 1 1 1 1

93-2

Gasket, Suction

Flange (2)

CS71200-100N JIS20K 100A(4") 1 1 1 1 1

94-1 Hexagon Head Bolt NB12022-055 M22×55 12 12 12 12 12

94-2 Hexagon Head Bolt NB12020-055 M20×55 8 8 8 8 8

95-1 Discharge Flange (1) CS71300-100 JIS20K 100A(4") 1 1 1 1 1

95-2 Discharge Flange (2) CS71300-080 JIS20K 80A(3") 1 1 1 1 1

96-1

Gasket, Discharge

Flange (1)

CS71200-100N JIS20K 100A(4") 1 1 1 1 1

96-2

Gasket, Discharge

Flange (2)

CS71200-080N JIS20K 80A(3") 1 1 1 1 1

97-1 Hexagon Head Bolt NB12020-055 M20×55 8 8 8 8 8

97-2 Hexagon Head Bolt NB12020-055 M20×55 8 8 8 8 8

100

Mechanical Seal

Assembly (BBSE)

CS10002-200EBS BBS-E 1 1 1 1 1

120-1

Unloader Indicator

Assembly (1)

CS12000-1612F 1612LSC 1 1 1 1 1

120-2

Unloader Indicator

Assembly (2)

CS12000-200F 200*** 20-100% 1 1 1 1 1

151 Driven Sleeve CS15100-2016 1 1 1 1 1

152 Drive Hub 1 1 1 1 1

153 Driven Hub 1 1 1 1 1

154

Stopper, Driven

Sleeve

CS15400-2016C 2 2 2 2 2

155 Stop Ring FRS-90 4 4 4 4 4

Loading...

Loading...