55

NOTICE: It is necessary to remove the Shrouds for this procedure. Refer to the “Replace the Shrouds” procedure.

It may be necessary to adjust the Brake tension at the end of this procedure. Refer to the “Set the Brake Tension” procedure.

Note: Your machine may not match the image. For reference only.

1. Disconnect and reconnect the AC Adapter from the wall outlet to

turn the power off and on. Push QuickStart and verify that the console

shows that the default resistance level is 4. Set the resistance to the

highest level.

Disconnect all power and allow to sit for 5 minutes.

2. Carefully remove the Shrouds. Refer to the “Replace the Shrouds”

procedure in this manual.

3. Measure and mark the position of the Servo Motor bracket (A) on

the Main Frame.

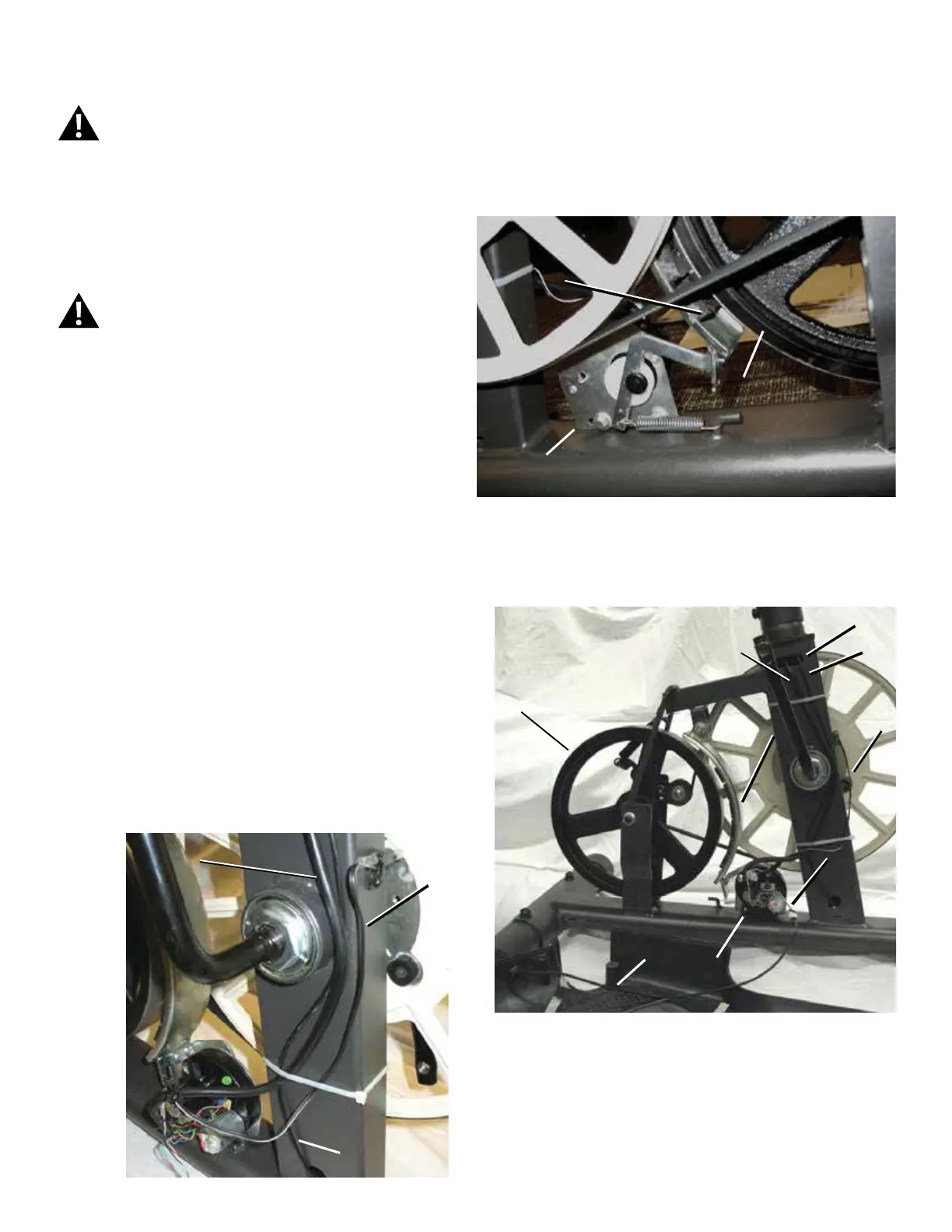

4. Insert 2.5” x 10” cardboard between the Brake Magnet (B) and the

Flywheel (C), and tape the cardboard to the Brake Magnet.

Note: Be sure the cardboard covers all of the Brake Magnet.

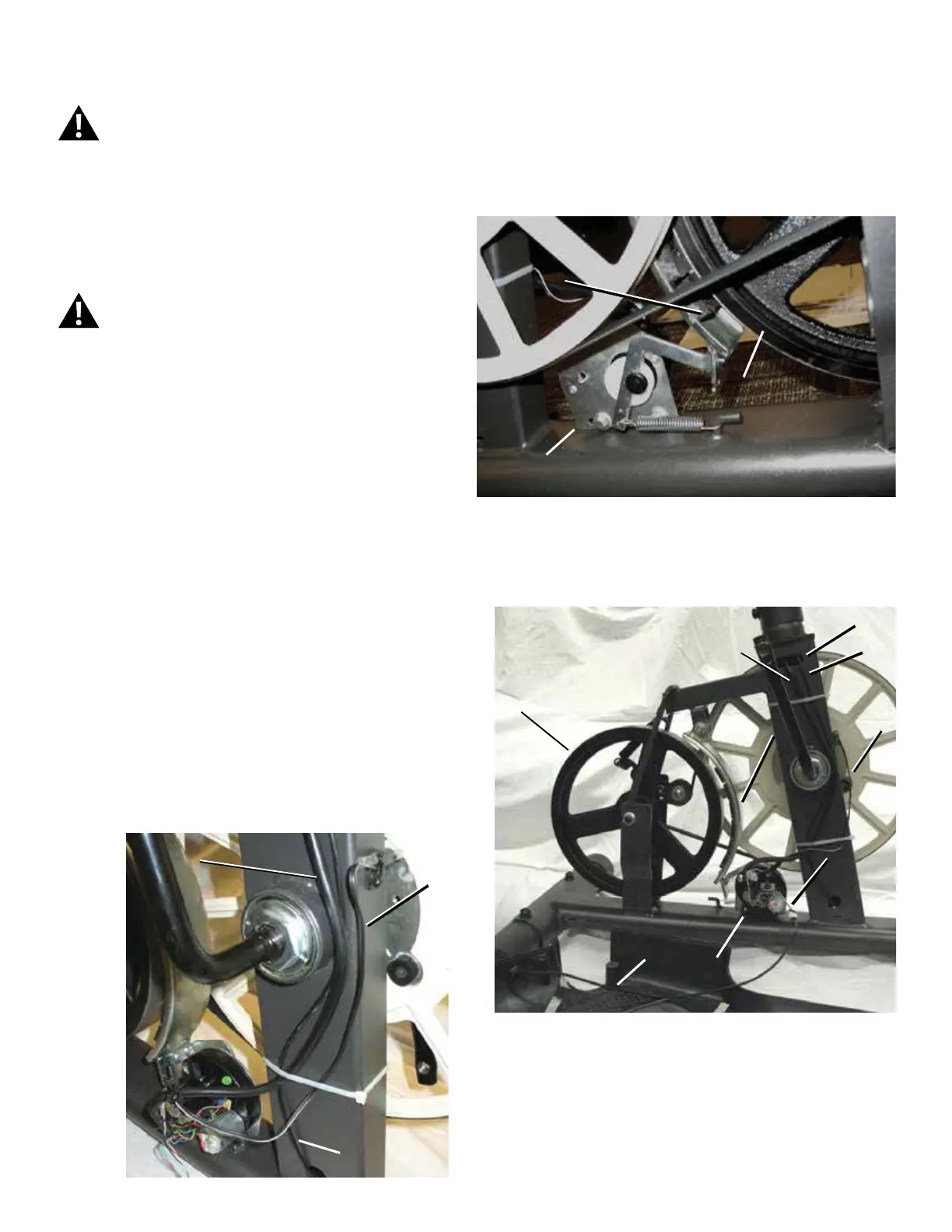

5. Observe the cable routing to the wiring harness (F) on your machine.

Disconnect the Speed Sensor Cable (D) and Power Inlet Cable (E) from

the wiring harness.

6. Tie the length of string to the end of the lower Console Cable (G)

at the top of the Mast mount. Remove the zipties that attach the lower

Console Cable to the Frame. Pull the cable and string down through the

hole (H) on the side of the Frame so that the string extends through the

Frame.

Note: Do not let the HR Cable (I) fall down inside the Frame.

Disconnect all power to the machine before you service it.

$

B

C

C

E

$

)

D

I

G

H

B

G

D

I

Loading...

Loading...