51

Fault Finding

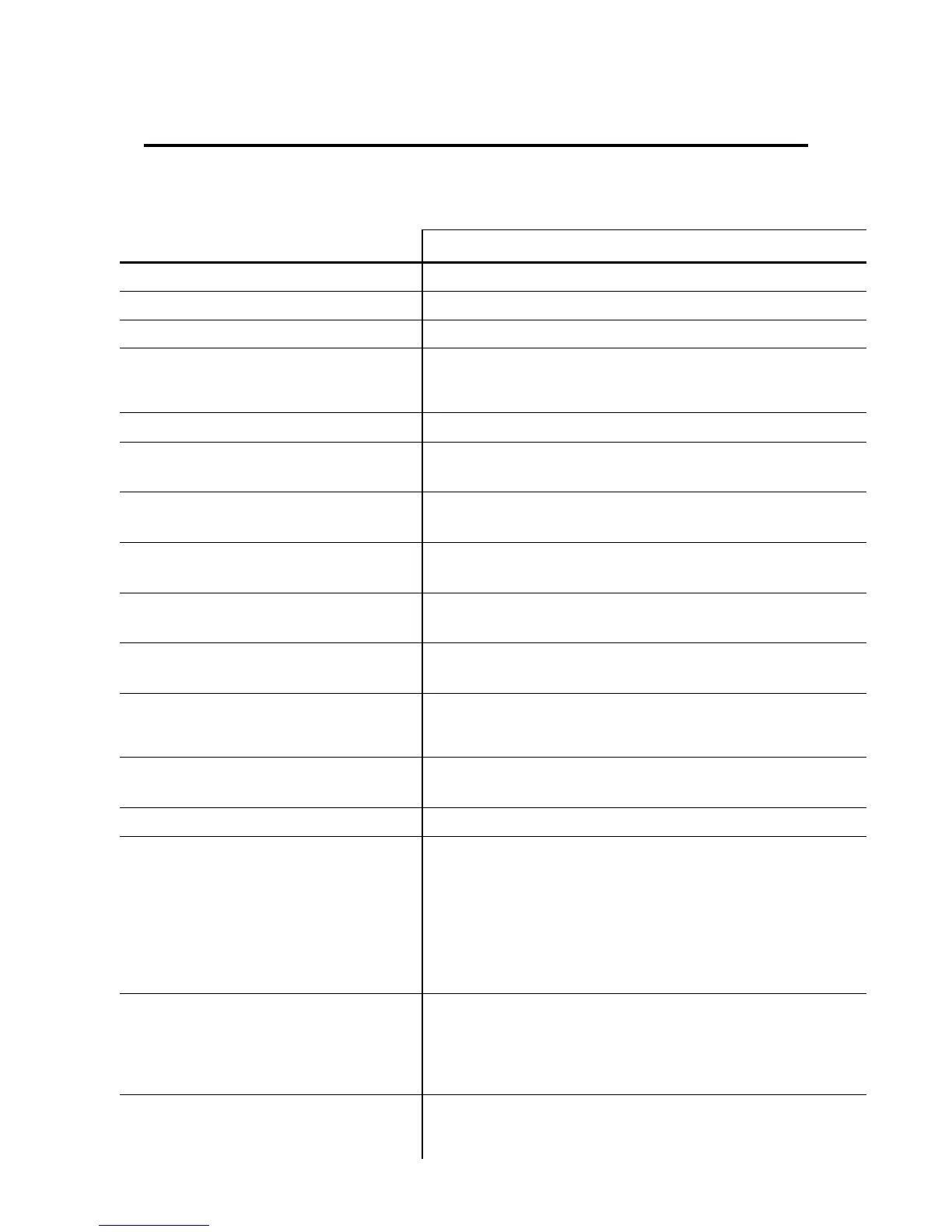

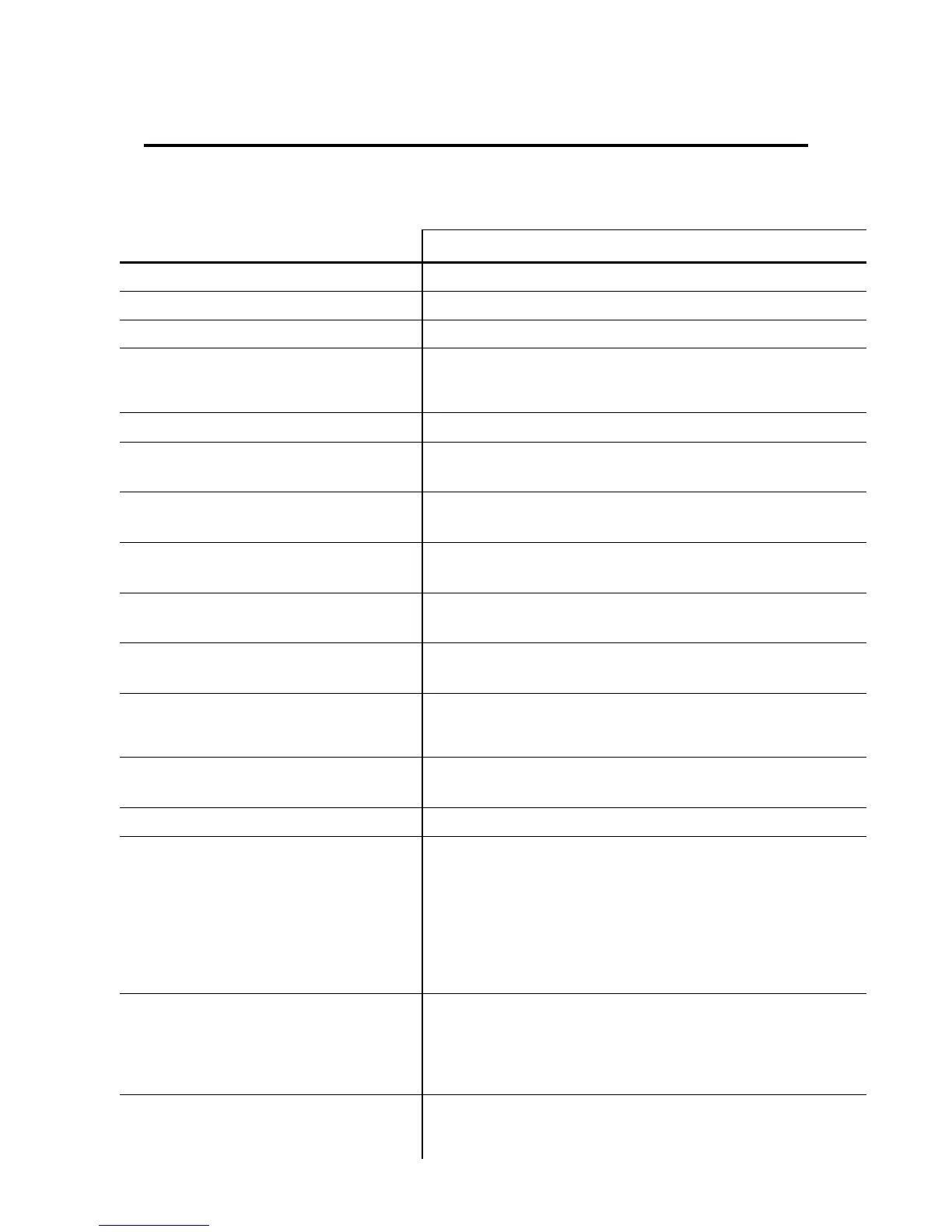

CHART A1—Dumper will not start or difficult to start (no exhaust

smoke)

Cause

Remedy

No fuel in tank. Check the level in the fuel tank and replenish as required.

Display gauge not powering up.

•

Check battery.

•

Check main line fuses 30A & 100A.

•

Check fuses in fuse box behind the steering column plate.

Display powering up but not starting engine. Check the start inhibit relay behind the steering column plate.

Fuel filter blocked with water or other

contamination.

Drain fuel/water separator or replace fuel filter.

Fuel lift pump not operating correctly (fuel

supply inadequate).

Check that the lift pump is operating and delivering fuel to the

injection pump.

Electrical fuel shut-off solenoid (ESOS)

valve not functioning properly.

Check for correct operation of the ESOS.

Not in Neutral. Check the FNR lever is in the NEUTRAL position.

Fuel is aerated. Check the fuel system for loose connections and possible air

ingress points. Rectify and bleed the fuel system.

Check the fuel inlet restriction. Maximum inlet restriction to the fuel transfer pump must not

exceed 100mm Hg (4” Hg).

Air intake or exhaust system is blocked. Visually check the air intake and exhaust intake for blockage or

obstruction, remove as required. Check the air filter elements for

signs of blocking, replace as required.

Fuel drain return line blocked or not

connected properly.

Verify that the fuel return line is not obstructed and connected to

the top of the fuel tank.

Fuel filter(s) blocked, fuel supply restricted. Check/replace the fuel filter(s). Check fuel lines for restriction

Worn or malfunction fuel injection pump

(FIP). Injection pump not delivering fuel.

Check for operation of the FIP.

The FIP must be taken to a local FIE specialist to have the fuel

delivery timing checked. Ensure that all obvious causes have been

eliminated before removing the FIP. (Needs to be, Delphi DP210

capable agent for mechanical engines and for common rail

electronic engines see Delphi agent or JCB dealer

(www.delphi.com or www.jcb.com)

Injection pump timing incorrect. If the pump has recently been removed and replaced the timing

could be incorrect if the correct removal procedures were not

followed.

The timing can only be checked by a FIE specialist using the

correct equipment.

One or more injector worn or

malfunctioning.

Check and externally clean the injector. If the problem still

persists, the injector must be checked by a FIE specialist or replace

with new.

Electrical isolator not turned on. Turn isolator on.

Loading...

Loading...