21

Service Schedules

CALENDAR EQUILIVANTS

50 Hours = Weekly

100 Hours = Fortnightly

500 Hours = Six Months

1000 Hours = Yearly

2000 Hours = 2 Years

Service checks should be carried out at which ever interval occurs first.

Do not use a machine which is due for a service. Make sure any defects

found during the regular maintenance are rectified immediately.

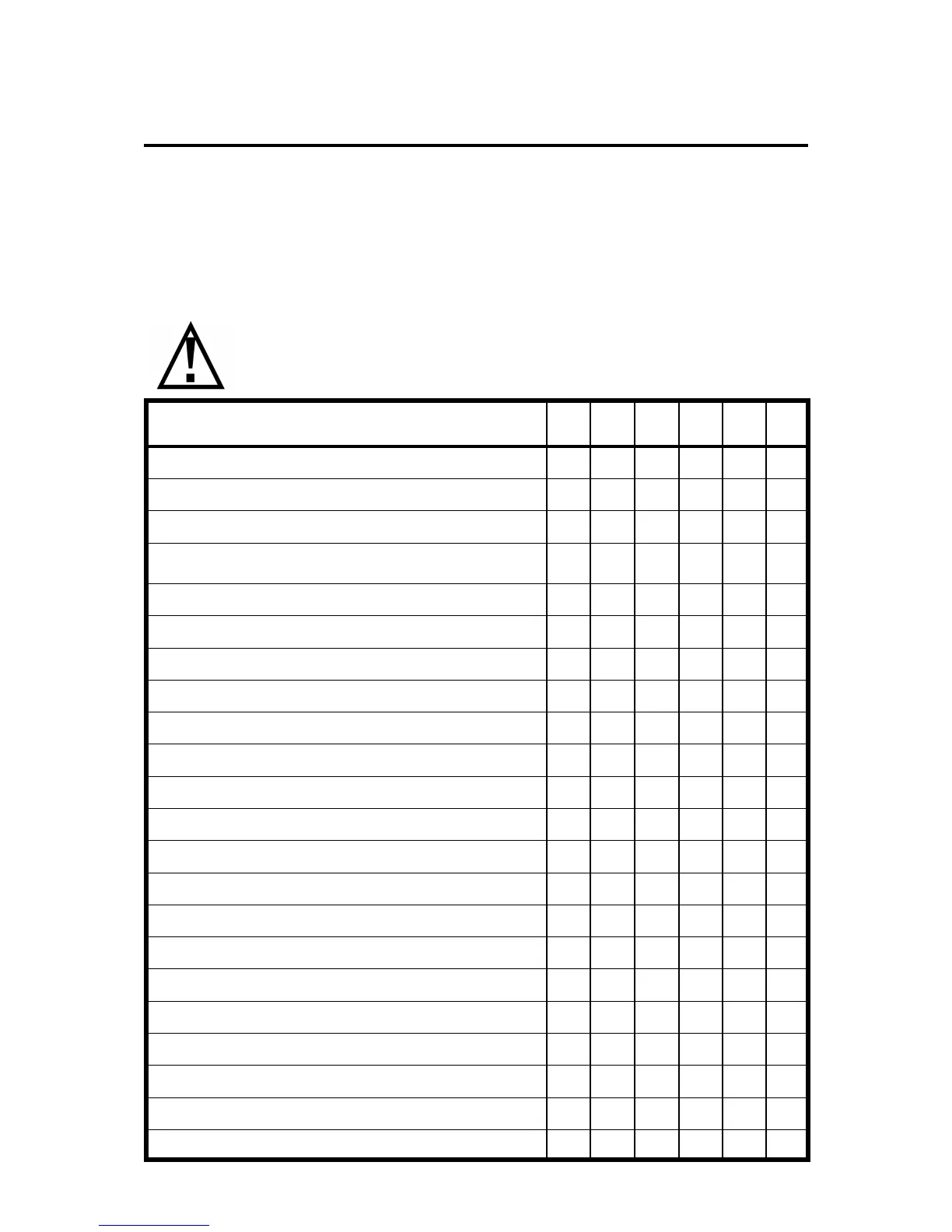

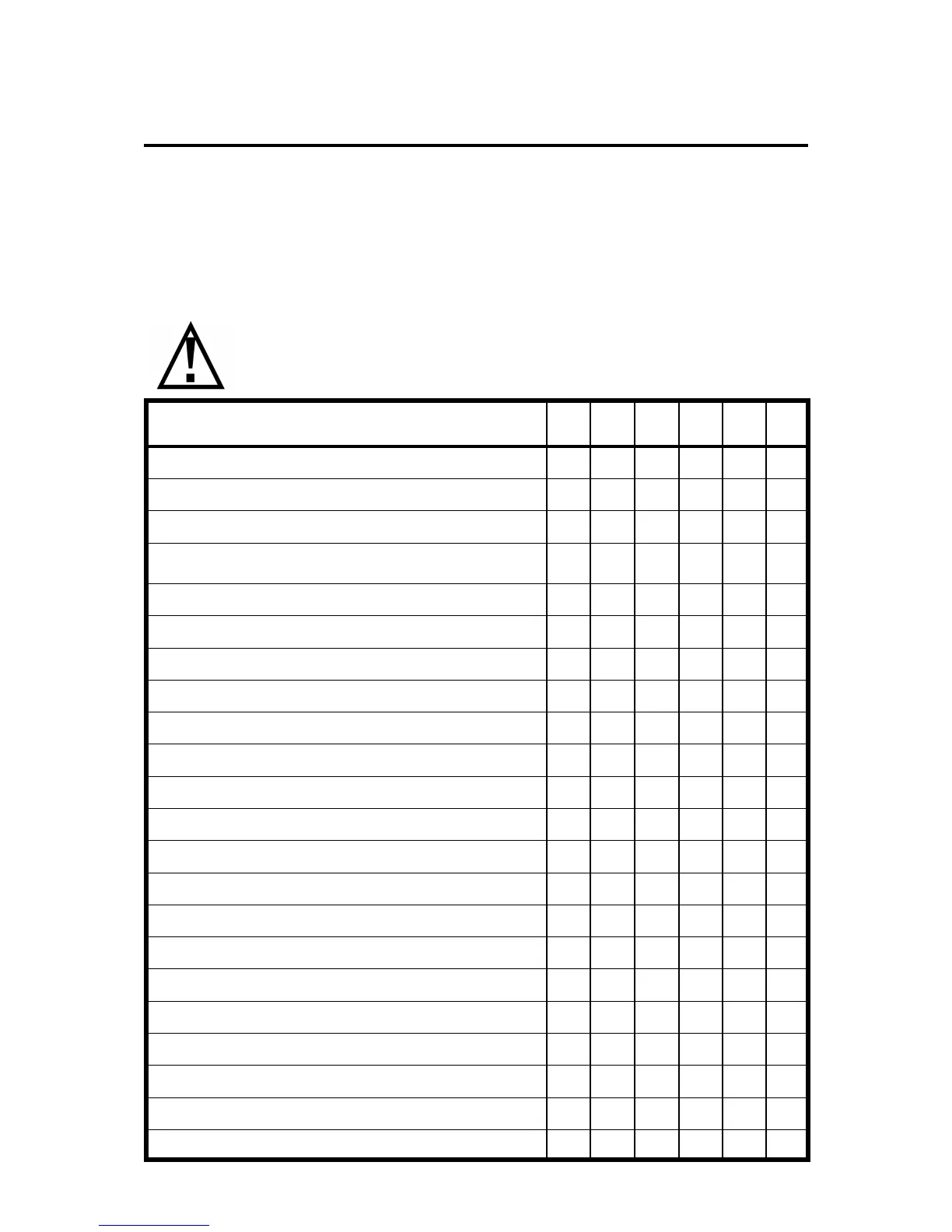

ENGINE

Service Points & Fluid Levels

Operation 10

Hr

50

Hr

500

Hr

1000

Hr

2000

Hr

6000

Hr

Oil level Check ●

Coolant Quality / Level Check ●

Coolant or Oil Leaks Check ●

Fuel Pre Filter & Water Sedimentor Check for contamination

& Drain

●

Oil & Filter ¹ Change ●

All Hoses—Condition Check ●

Radiator Clean ●

Fan Belt Condition Check ●

Fuel Filter Change ●

Air Cleaner Outer Element Change ●

Air Cleaner Inner Element Change ●

Valve Clearances Check & Adjust ●

Breather Gauze Clean ●

Oil Filler & Dipstick O Rings Change ●

Low Idle Speed Check & Adjust ●

●

Rocker Cover Seal & Injector Seals Change ●

Fan Belt Change ●

Injectors Change ●

Injector(s) Leak-Off Rail Change ●

High Pressure Fuel Lines Inspect ●

Cooling System Drain & Fill

Fuel Pre Filter Element (on dumper adjacent to radiator) Change ●

¹ If operating under arduous conditions change the engine oil & filter every 250 hours.

Loading...

Loading...