56

Fault Finding

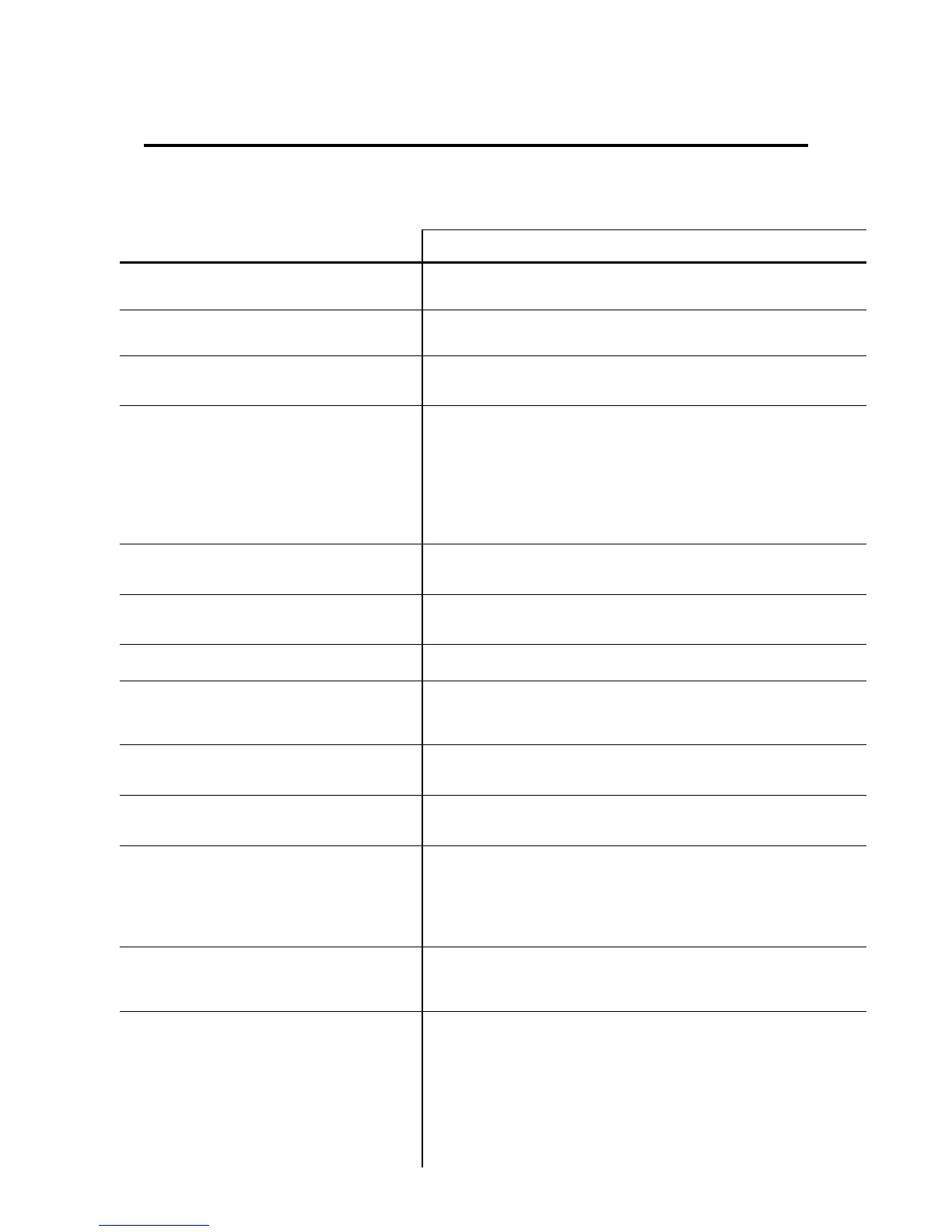

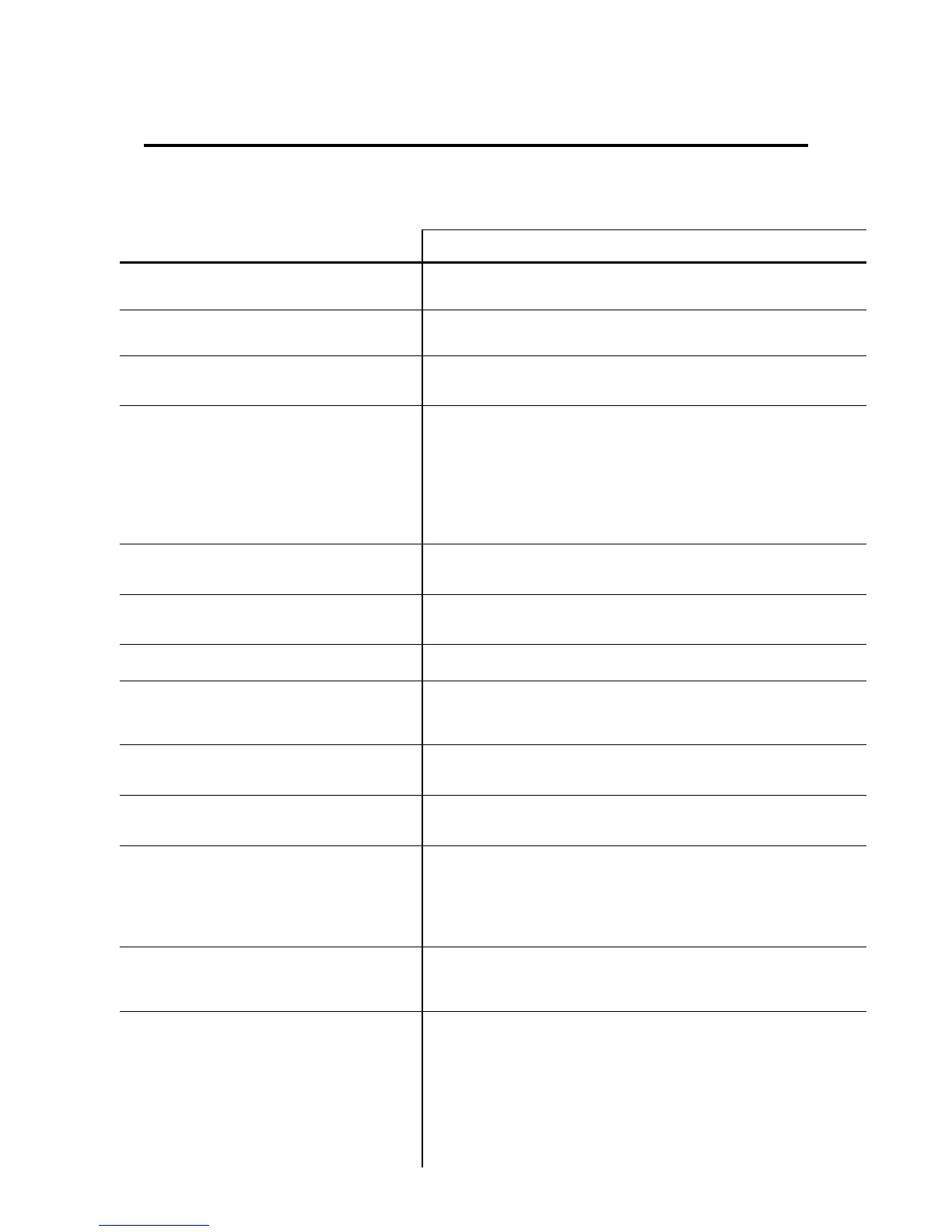

CHART A6—Engine poor running at idle

Cause

Remedy

Engine is cold. Cold starting aid is not

working.

Check for the correct operation of the cold start advance. If the

engine will not reach operating temperature, refer to Chart D3.

Idle speed too low for accessories. Adjust the idle speed. Refer to the machines service manual for

correct adjustment procedures and idling speed.

Engine mounts over-tightened, damaged or

loose.

Verify the condition of the mounts, and replace/adjust as

necessary.

Fuel injection lines leaking. Inspect and correct as required leaks in the high pressure lines,

fittings injector sealing washers, or delivery valves.

WARNING: Fine jets of fluid can penetrate the skip. Keep face

and hands well clear of pressurised fluid and wear protective

glasses. If fluid penetrates your skin seek medical help

immediately.

Fuel is aerated. Check the fuel system for loose connections and possible air

ingress points. Rectify and bleed the fuel system.

Fuel lift pump not operating correctly (fuel

supply inadequate).

Check that the lift pump is operating and delivering fuel to the

injection pump.

Fuel filter(s) blocked, fuel supply restricted. Check/replace the fuel filter(s). Check fuel lines for restriction.

Fuel is contaminated or incorrect grade of

diesel used.

Refer to Fluids & Lubricants section for recommended diesel

fuels. If the fuel is suspect, verify by operating the engine with

clean fuel from a temporary tank.

Inlet and exhaust valve clearances set

incorrectly.

Set the valve clearances to the recommended clearances.

Engine compression low in one or more

cylinders.

Check the engine compression.

Injection pump timing incorrect. If the pump has recently been removed and replaced the timing

could be incorrect if the correct removal procedures were not

followed.

The timing can only be checked by a FIE specialist using the

correct equipment.

One or more injector worn or

malfunctioning.

Check and externally clean the injector. If the problem still

persists, the injector must be checked by a FIE specialist or replace

with new.

Worn or malfunction fuel injection pump

(FIP). Injection pump not delivering fuel.

Check for operation of the FIP.

The FIP must be taken to a local FIE specialist to have the fuel

delivery timing checked. Ensure that all obvious causes have been

eliminated before removing the FIP. (Needs to be, Delphi DP210

capable agent for mechanical engines and for common rail

electronic engines see Delphi agent or JCB dealer

(www.delphi.com or www.jcb.com)

Loading...

Loading...