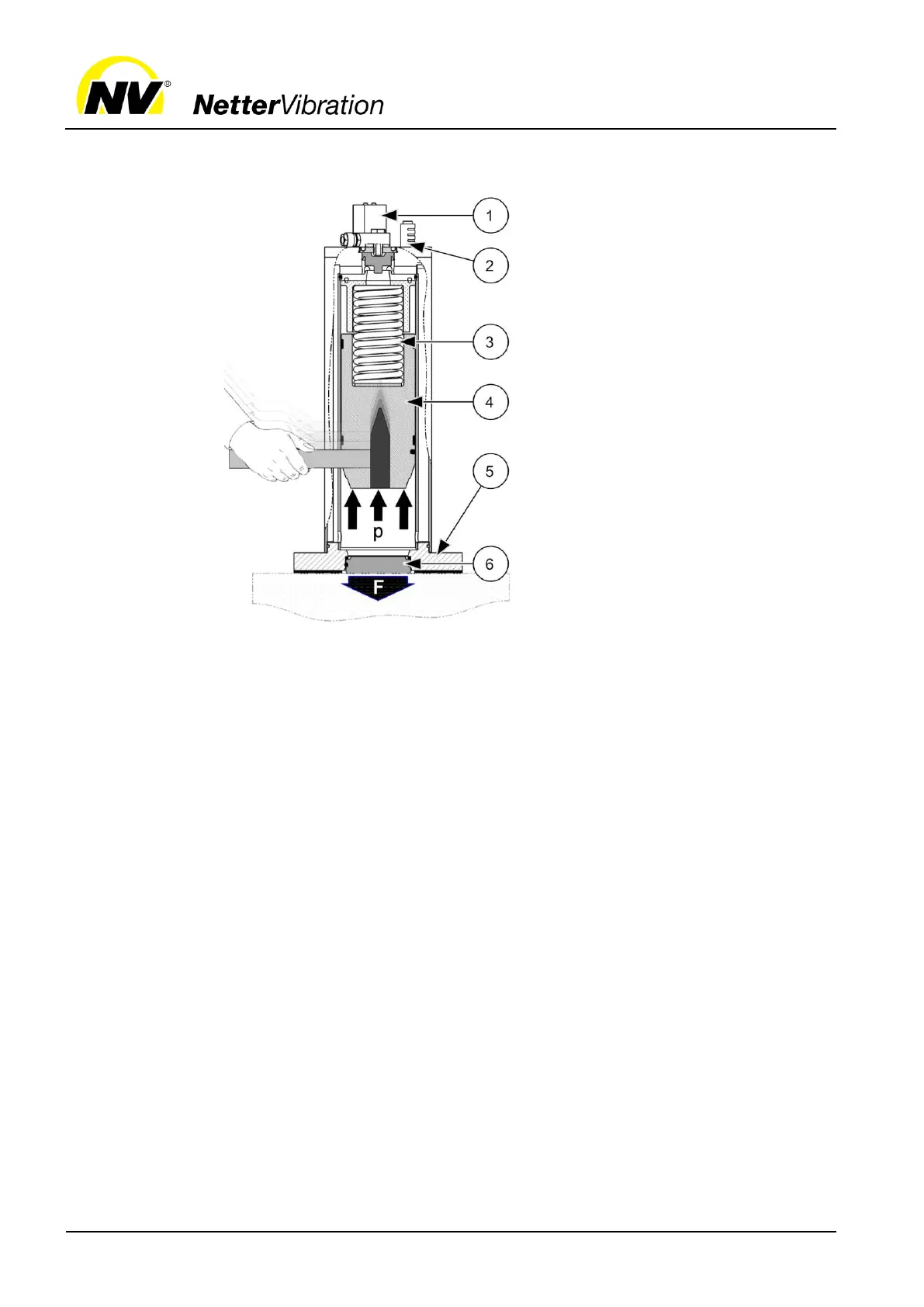

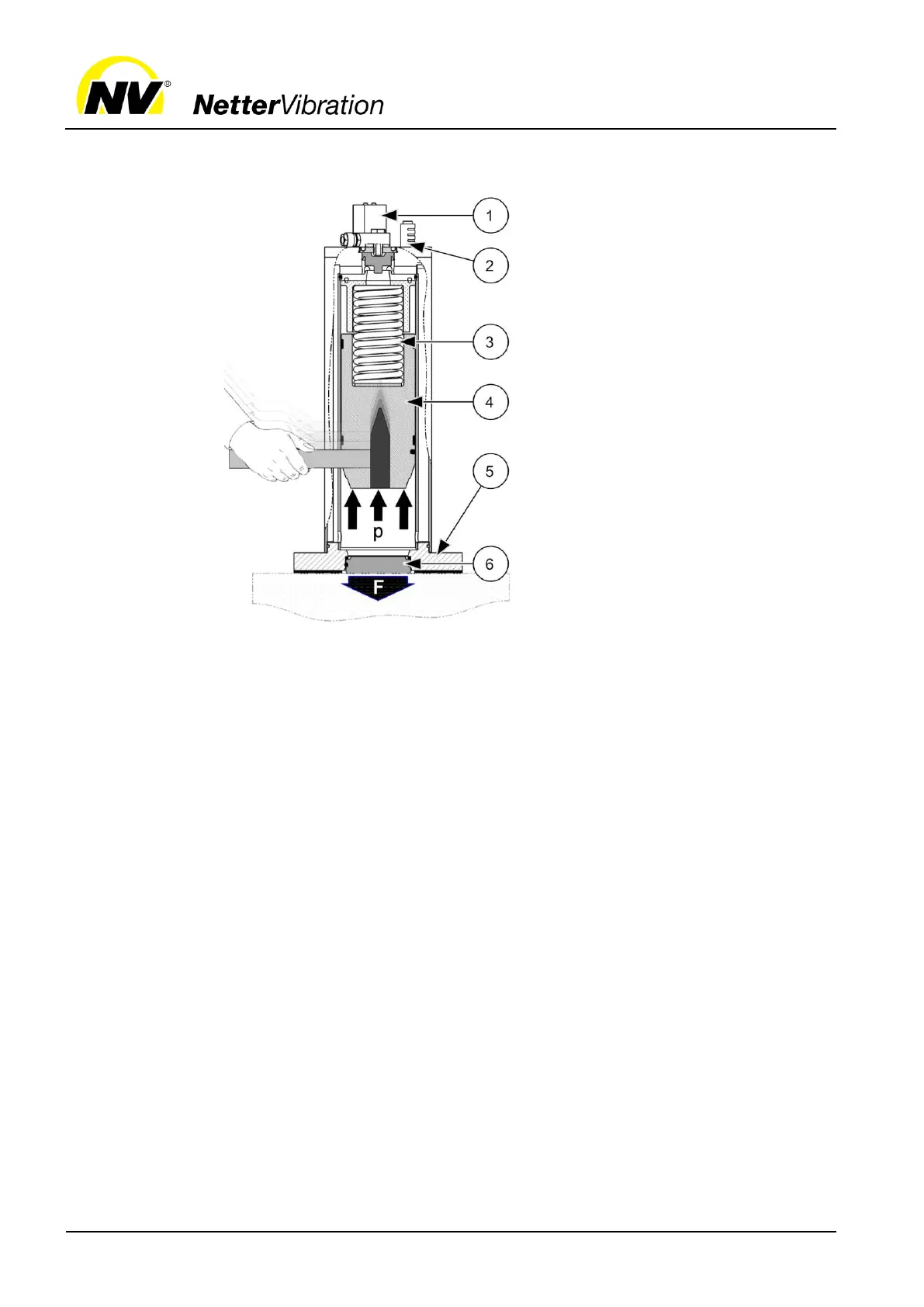

The PKL is a pneumatic "hammer". Compressed air goes under the pis-

ton (4) and presses it against one or two springs (3).

When exhausting, the air chamber beneath the piston empties abruptly via

the quick air-exhaust valve (1).

The piston (4) (hammer) is struck by the spring force against an impact

plate (6), which then passes the impact force (F) on. For PKL without an

impact plate (PKL 190, PKL 450 and PKL 740), the piston strikes directly

against the fastening surface. The PKL 1000, PKL 2100, PKL 5000 and

PKL 10000 have an impact plate.

The air escapes via the silencer (2).

The PKL only work when mounted, as the piston chamber is then sealed

by a built-in O-ring in the mounting surface (until PKL 740) or by a damper

ring (flange; from PKL 1000 on).

A quick-air exhaust valve and a 3/2-way valve are integrated in the valve

head of the PKL 740. Therefore, the control valve on the customer's site

can be mounted at any distance away from the PKL 740.

The control air must be connected at the side. A silencer is mounted on

the exhaust air outlet.

The ST kit allows a continuous impact sequence with permanent com-

pressed air supply.

The EE kit generates a "rubber hammer effect" and reduces the noise lev-

el.

Loading...

Loading...