Special transport conditions are not required.

When moving the PKL 10000, use the mounted transport lugs at the top of

the housing.

The PKL are packed and ready for assembly. Accessories and add-on

parts are delivered unmounted, unless otherwise agreed upon.

The packaging protects the PKL from transport damage. The packaging

material has been selected from an environmentally safe and technically

disposable point of view and is therefore recyclable.

The return of packaging to the material cycle conserves raw materials and

reduces the amount of waste.

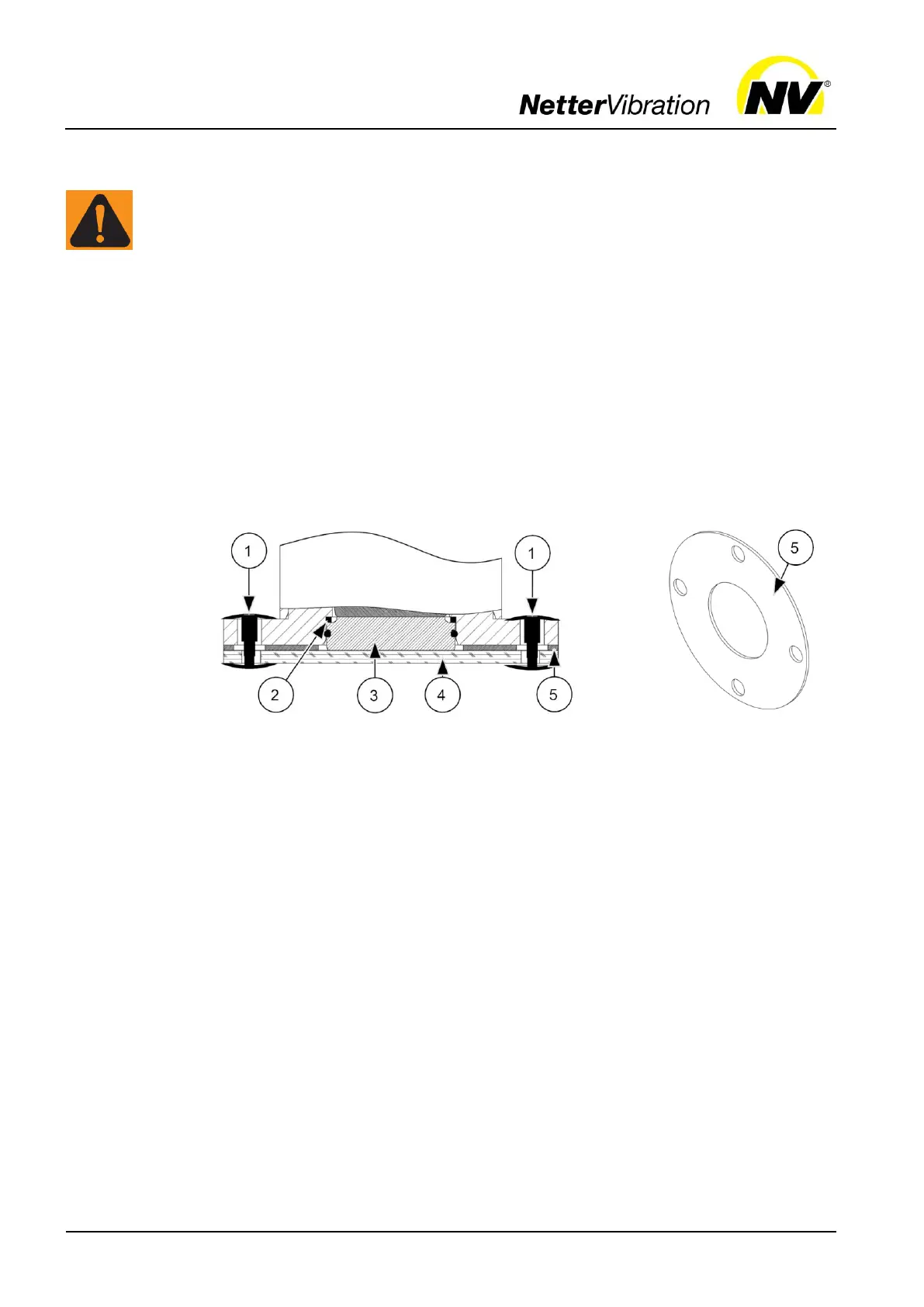

The PKL 1000, PKL 2100, PKL 5000 and PKL 10000 are delivered with a

transport safety device at the bottom. The transport safety device consists

of two plastic fastenings (1) and a corrugated cardboard disc (4). It pre-

vents the impact plate (3) from falling out during transport and must be

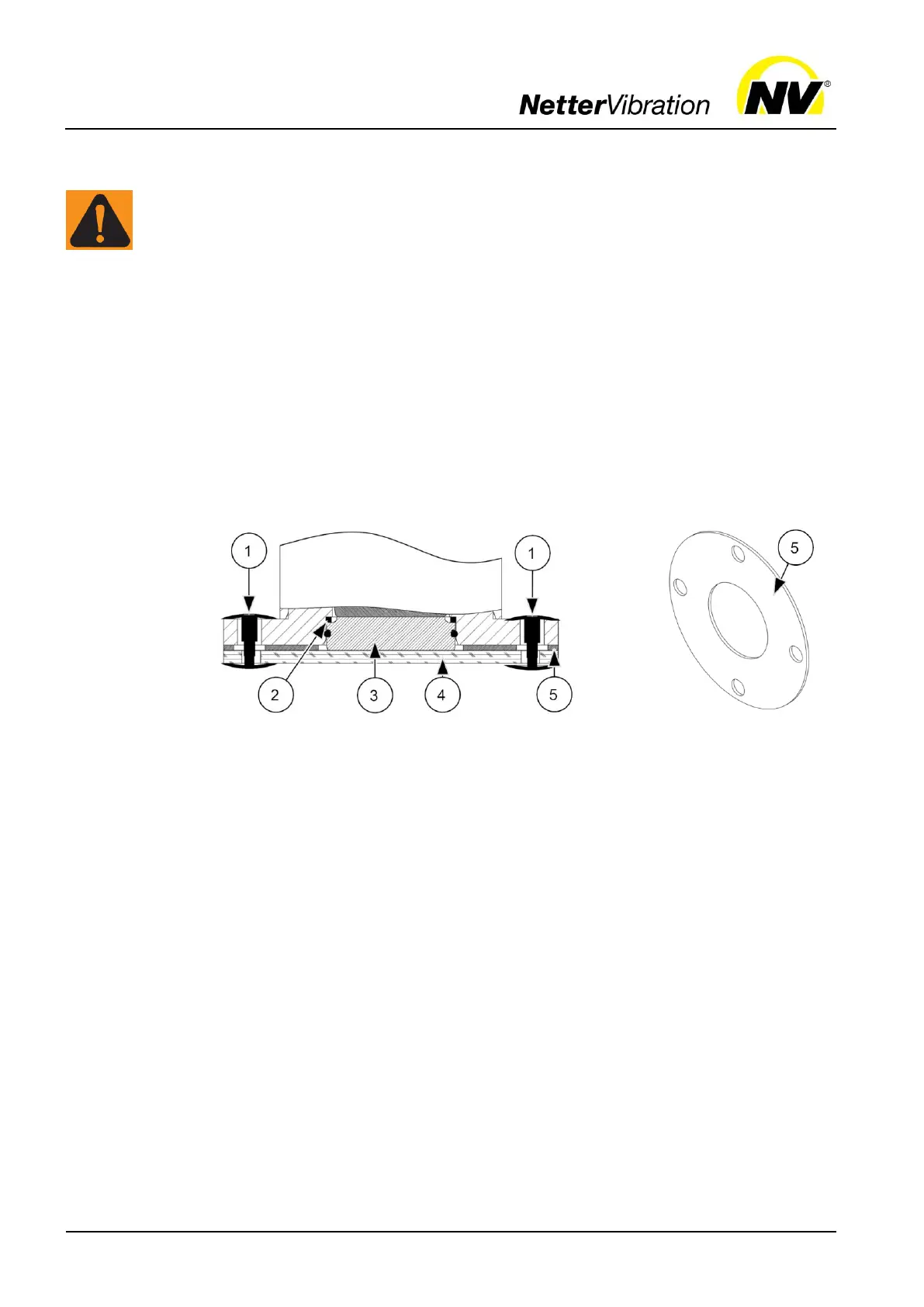

removed before installation. Take care that the impact plate and damper

ring (flange; 5) retain their position on the PKL, as they must be mounted

with the PKL.

• Store the PKL in a dry and clean environment.

• Protect the PKL from UV-exposures, weather and ozone.

• The storage temperature is between -20 °C and +60 °C.

• Close all openings when re-storing.

• Preserve the PKL before storage:

1. Mount the PKL on a plate. The impact plate of the PKL 1000,

PKL 2100, PKL 5000 and PKL 10000 must be inserted.

2. Apply anti-corrosion oil to the air inlet and briefly activate the PKL.

Loading...

Loading...