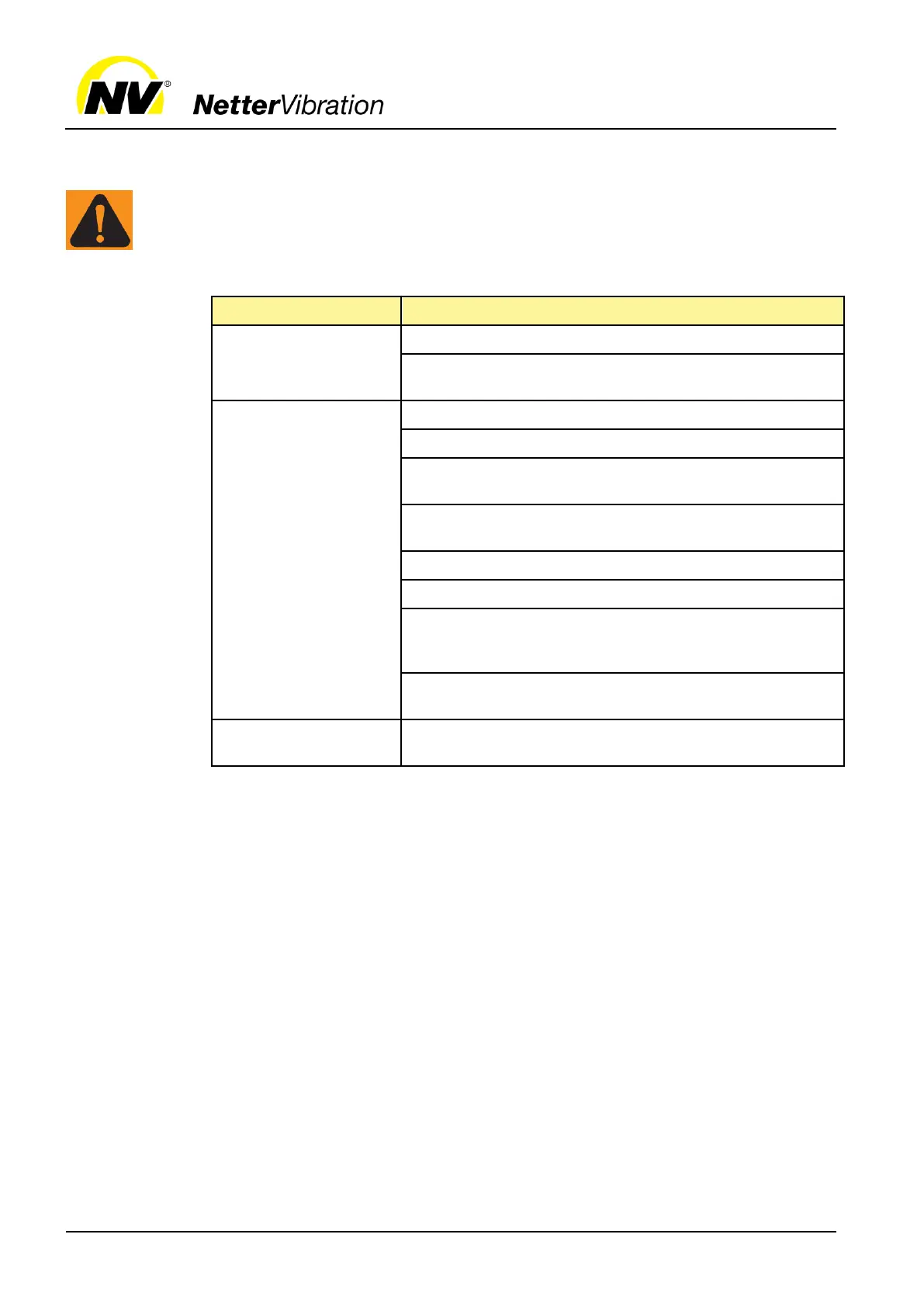

Maintenance and servicing

8 Maintenance and servicing

Observe the safety instructions in Ch. Safety, from page 5 on.

Maintenance of the PKL must be carried out as follows:

After one hour of opera-

tion after initial commis-

sioning

Check hose screw connections and hose connections and

retighten, if necessary.

Check hose screw connections and hose connections and

retighten, if necessary.

Check hose supply connections for permeability and kinks. If

necessary, clean and remove kinks.

Check the function of the silencer.

For installation with mist lubricator:

Ensure that mist lubricator operates according to regulations.

Refill oil.

Empty the filter of the maintenance unit if necessary, clean

the filter insert (wash out) and replace if necessary.

At the latest after a total

of 500,000 strokes

Carry out the general overhaul, in which all wear parts must

be replaced.

In the course of its service life, a film can form due to wear, which impairs

functioning. If loss in performance or standstill is noticed, proceed as fol-

lows:

1. Remove piston.

2. Clean piston.

3. Replace guide ring and piston seal, if necessary.

4. Reinsert piston.

Special tools are needed for inserting piston, guide rings and piston seal

(available on request).

The maintenance intervals depend essentially on the service life and how

clean the drive medium is.

Unfiltered compressed air leads to high wear, silencer clogging or com-

plete failure of the PKL.

Maintenance, repair and general overhaul of the PKL may alternatively be

performed by

Netter

Vibration.

Implementa-

tion by Netter

Loading...

Loading...