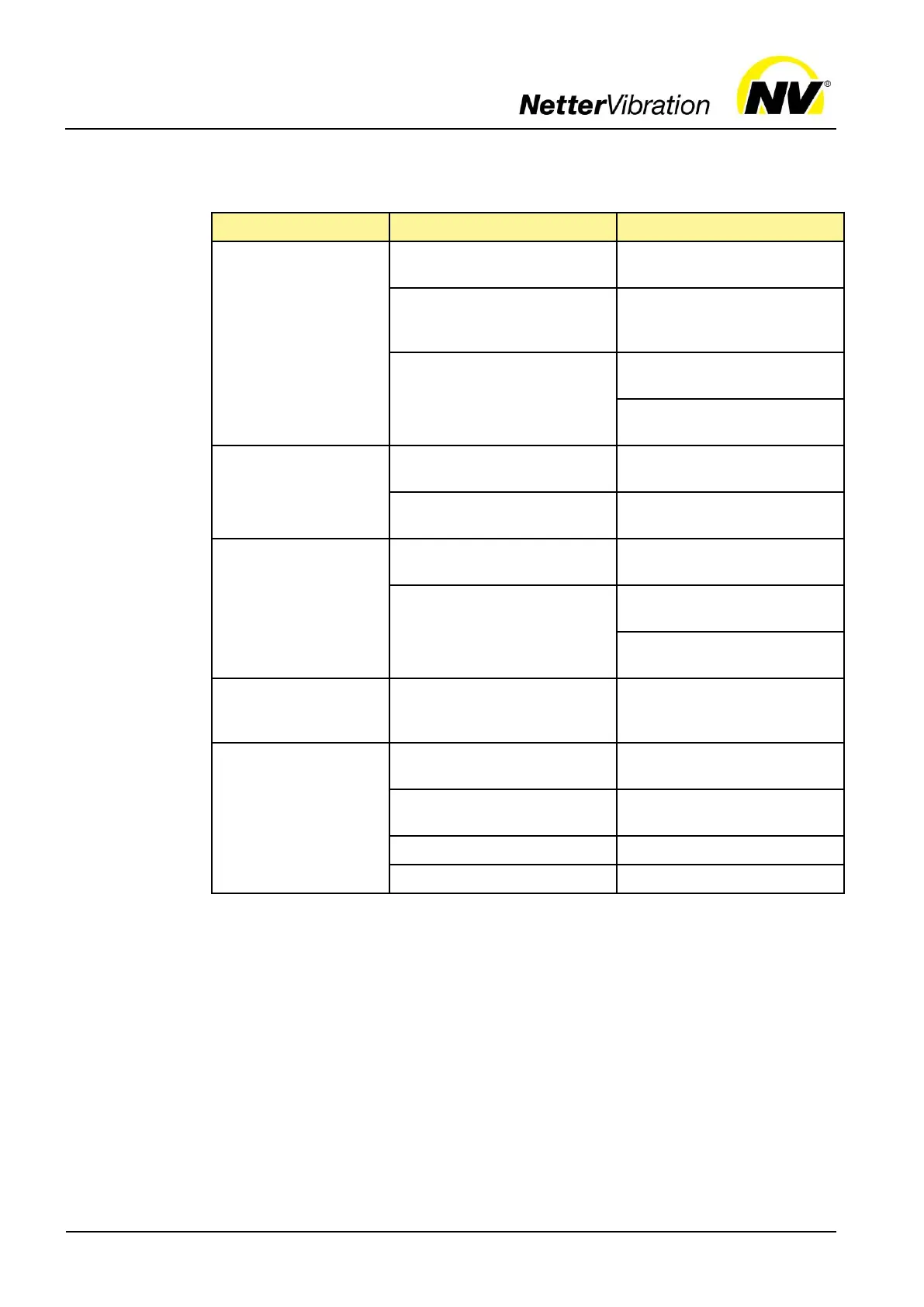

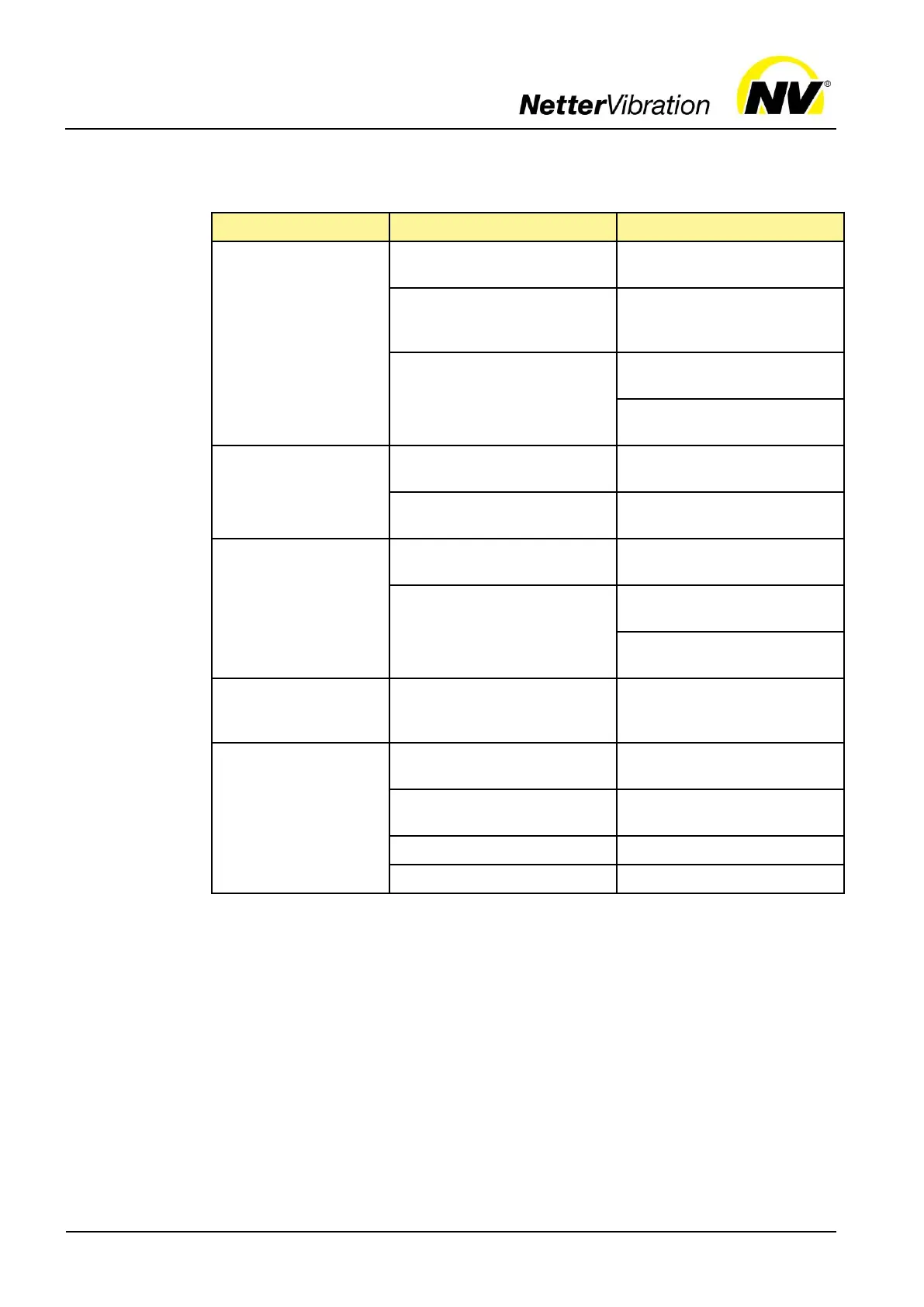

9 Troubleshooting

In the case of malfunctions of the PKL proceed as follows:

Mounting surface not flat, loss

of pressure via O-ring

Establish ±0.1 mm flatness on

mounting surface.

Malfunction of valve and con-

trol

Check PKL without valve and

control. Check valve and con-

trol, and replace if necessary.

Check pressure and increase

if necessary.

Check valve connection. Re-

place valve, if necessary.

Does not function and

has leakage at top

Check seals of impact piston,

replace if necessary.

General wear (Housing and

membrane)

Replace affected parts and

seals.

Does not function and

has leakage on mount-

ing surface

Tighten fastening screws and

replace, if necessary.

Mounting surface not flat

Establish ±0.1 mm flatness on

mounting surface.

Check O-ring. Insert O-ring in

groove, replace if damaged.

Does not function with

ST kit

Operating pressure insufficient

Check PKL model. Check

pressure and increase if nec-

essary.

Check pressure and increase

if necessary.

Contamination of control valve

Clean control valve or replace,

if necessary.

Contamination of silencer

Loading...

Loading...