USER MANUAL

8. Calculate the correction value according to the following formula:

𝑘 =

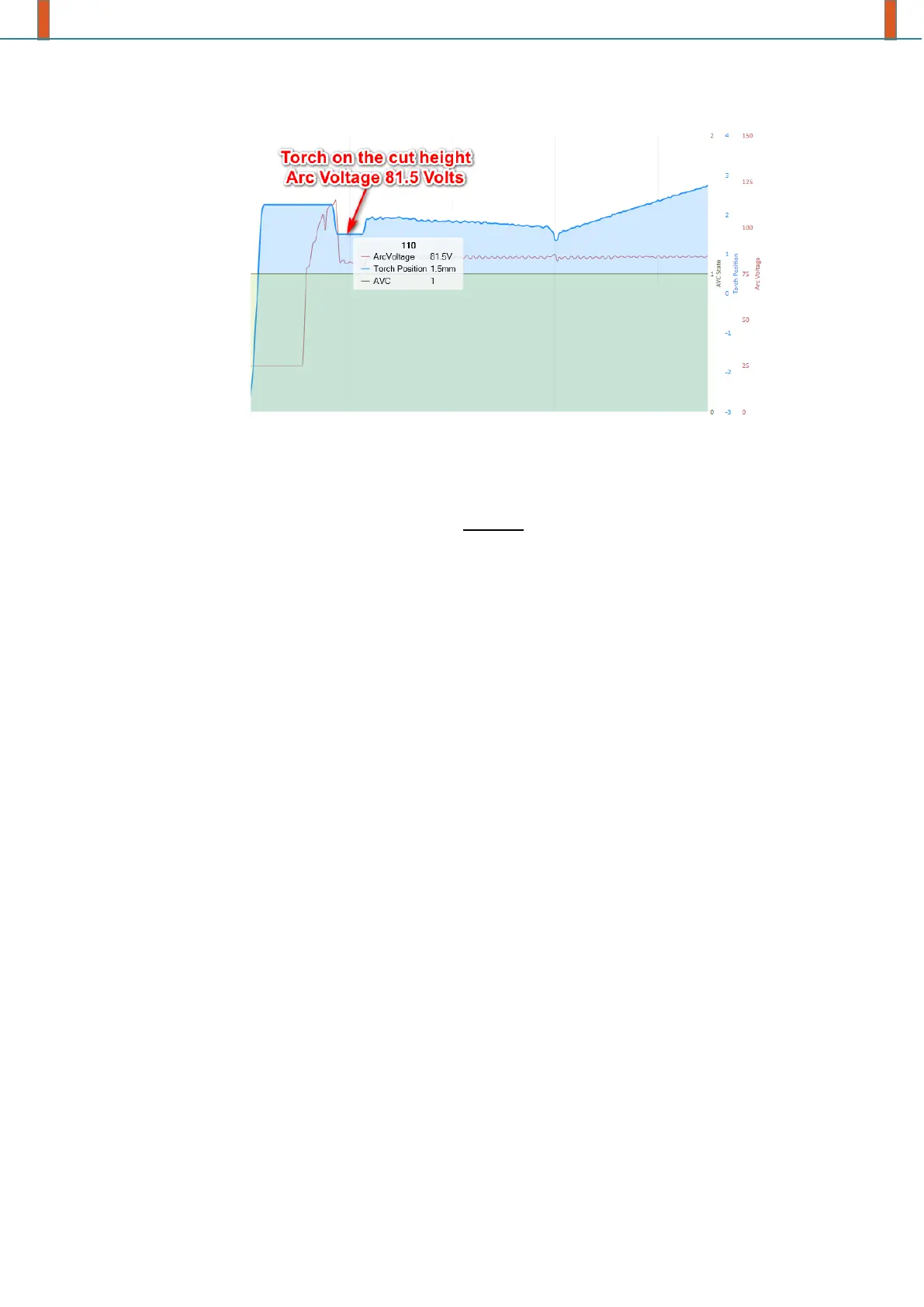

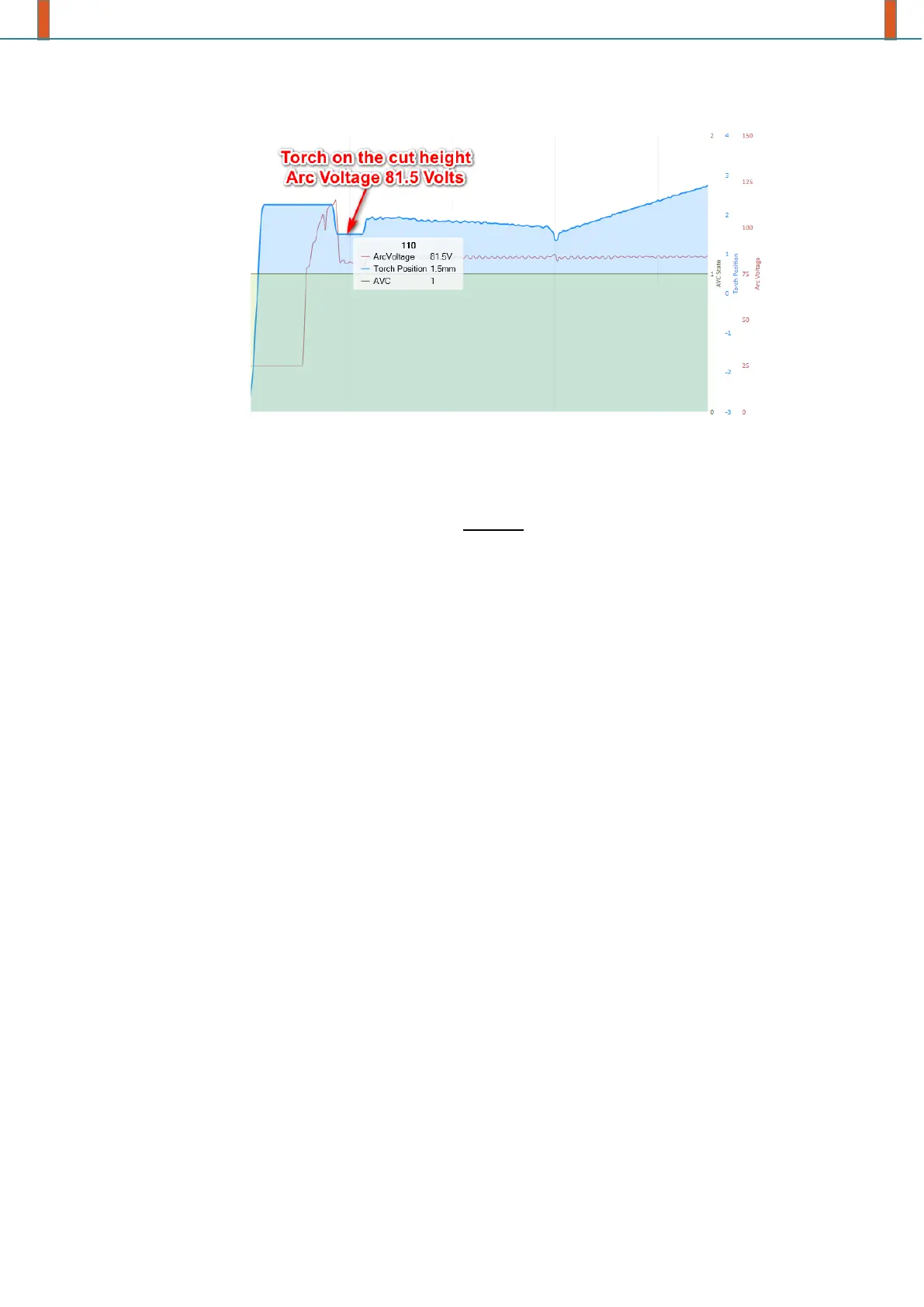

𝑉𝑏𝑜𝑜𝑘

𝑉𝑟𝑒𝑎𝑙

Where the 𝑉𝑏𝑜𝑜𝑘 is the value of the arc voltage recommended by the manufacturer for this cut

and the 𝑉𝑟𝑒𝑎𝑙 is the real arc voltage that the controller displayed during the cut.

Possible values of the correction value are in the range from 0.5 to 1.5.

Enter this value in the “Correction Value” box.

Float Head Microswitch offset setup

This future allows to setup offset of the float head switch.

Set “Start Setup” checkbox. Controller will start Initial Height Sensing procedure. When the IHS

will be completed the torch will be moved up on the 4mm for metric system or 0.2 in for inches

system under surface of the plate. Check the distance between the surface of the plate and torch

nozzle. If it’s not 4mm (0.2 in.) (check it for example by standard drill) correct it by rotating

multiturn encoder on the operator panel. For finish – uncheck “Start Setup” checkbox.

Marking mode

This mode can be used to marking (make small corner on the centers of the holes).

To do this, the controller will turn on the cutter and immediately off after receiving the ArcOk

signal from cutter.

Setting: Enable/Disable.

Ref Z axis after

This setting allows to make an automatic homing procedure after each count of the pierces.

Count can be set up to 30 pierces. Set “0” for disabling this future.

Ventilation

This future allows to control fume extractor motor. You can set “Rump UP” and “Post Flow

time”.

If “Neuron BOB” used – select from drop down list number of the output for motor on/off

control.

If “Neuron BOB” is not used – select “Not Use” and set port and pin for this output in the

Neuron Plugin THC configuration Window.

Loading...

Loading...