USER MANUAL

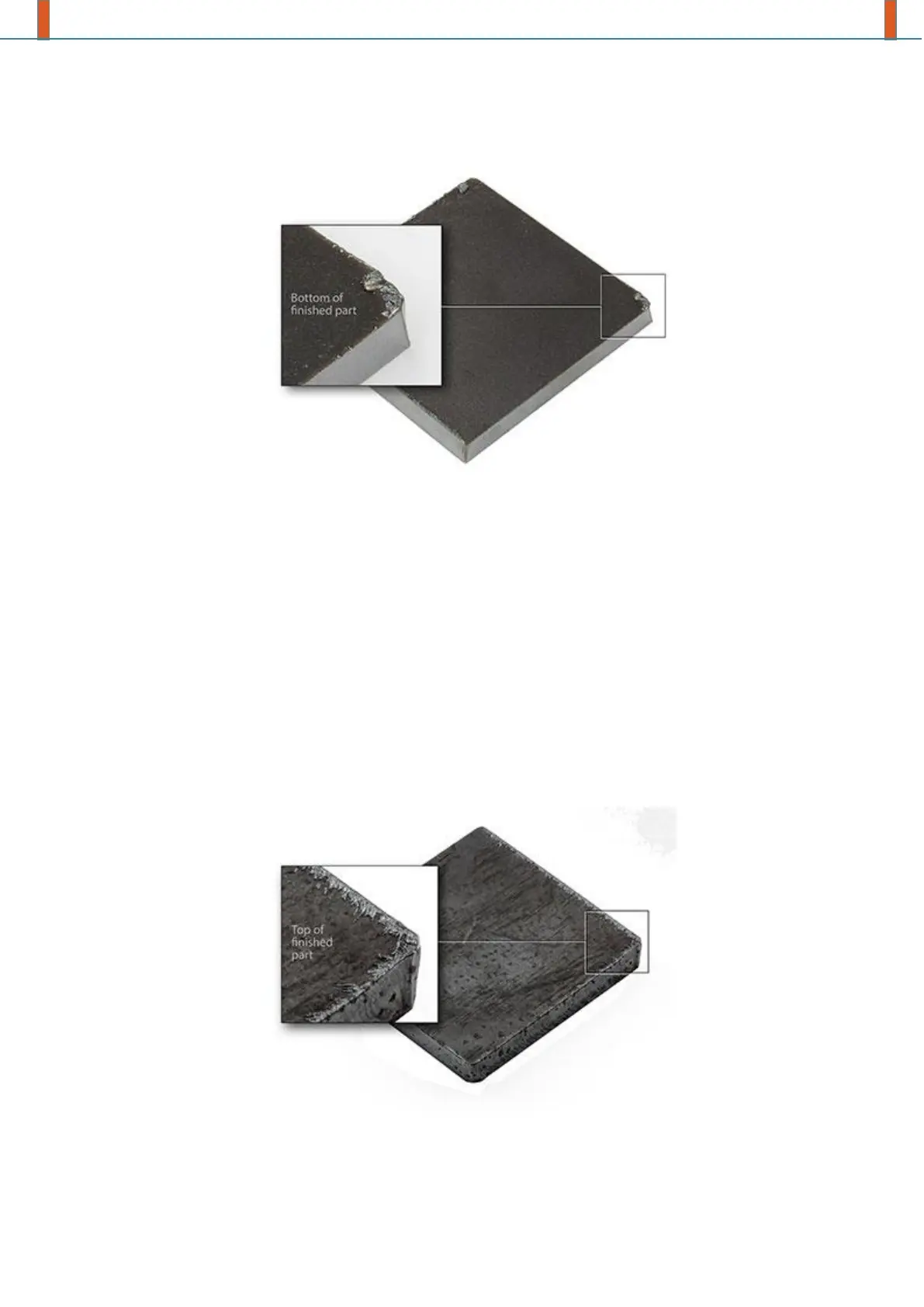

Corner Dross

Cause:

Dross will intermittently form in the corners of a part due to the speed reduction required for a

cutting machine to perform an extreme change in direction, such as a right angle. The likelihood

of this occurring varies depending on the thickness of the material, cutting amperage, and

material composition.

Solution:

This is a normal occurrence and cannot be avoided without altering the part drawing to include

options such as corner loops.

Fortunately, the amount of dross this condition presents is minimal and is easily removed with a

hand scraping tool.

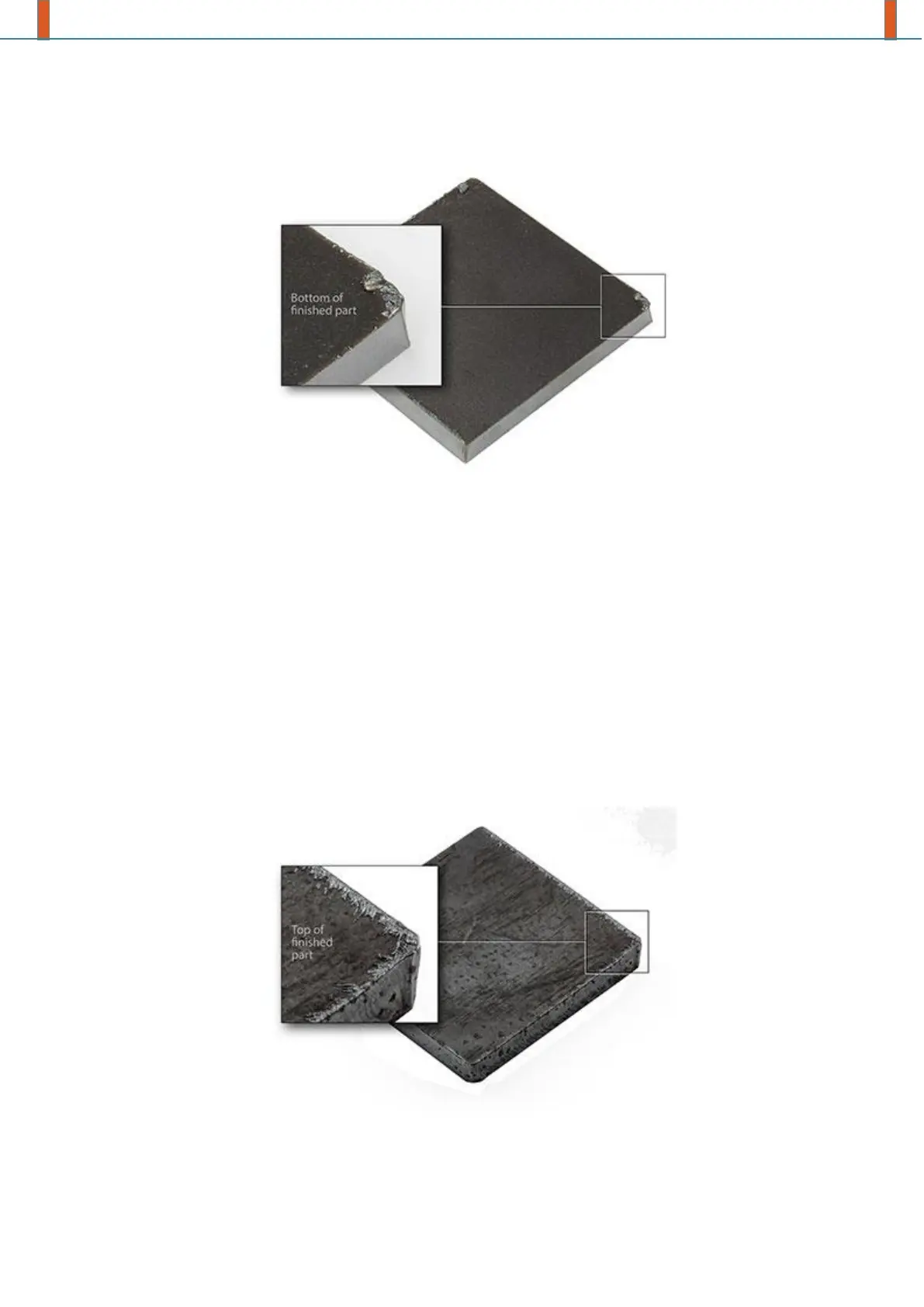

Top Dross

Cause:

Occasionally, small amounts of dross will form on the top of the part when the programmed

cutting speed is too fast or the torch standoff distance is too high. This is caused by the plasma

arc’s inability to blow all the molten metal through the bottom of the kerf when the tip of the

Loading...

Loading...