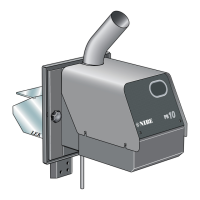

10 NIBE PB 10

Installation

Commissioning and adjusting

Adjustment template

Adjusting the burner

Q Check the pellet level. During operation the holes on

the grate must be covered with pellets.

Q Pellet supply changed using P2 on the circuit board

(increased clockwise and reduced anti-clockwise). Also

check the air damper and flue gas temperature.

Q In the event of the pellet level being too high, increase

the air supply by opening the damper on the fan or

reducing the pellet supply (P2).

Q Check the flue gas temperature (normally between

170–240 ºC). If the temperature is too high reduce the

pellet supply with P2.

Q If the temperature is too low, increase the air supply

with the air damper.

Q In the event of low fuel level in the burner. Check the

flue gas temperature as above, reduce the air supply or

increase the pellet supply (P2).

Make adjustments to the burner using a

flue gas analysis instrument for optimal

combustion.

Note!

P1 P2 P3 P4 P5

Supply time Firing supply Extinguishing

time

Overrun time Photocell

0 Flashes 30 seconds 1.5 seconds 30 seconds 45 seconds 0 sensitivity

1 Flashes 45 seconds 1.7 seconds 60 seconds 90 seconds 1 sensitivity

2 Flashes 60 seconds 1.8 seconds 90 seconds 135 seconds 2 sensitivity

3 Flashes 75 seconds 2.2 seconds 120 seconds 180 seconds 3 sensitivity

4 Flashes 90 seconds 2.8 seconds 150 seconds 225 seconds 4 sensitivity

5 Flashes 105 seconds 3.7 seconds 180 seconds 270 seconds 5 sensitivity

6 flashes 120 seconds 4.8 seconds 210 seconds 315 seconds 6 sensitivity

7 Flashes 135 seconds 6.2 seconds 240 seconds 360 seconds 7 sensitivity

8 Flashes 150 seconds 7.5 Seconds 270 seconds 405 seconds 8 sensitivity

9 Flashes 165 seconds 8.2 seconds 300 seconds 450 seconds 9 sensitivity

Factory setting 75 seconds 3.7 seconds 150 seconds 270 seconds 5 sensitivity

Default setting is shaded

When changing from 8 mm to 6 mm pel-

lets, the burner must be adjusted.

Note!

Loading...

Loading...