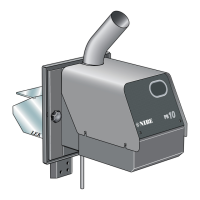

11NIBE PB 10

Installation

Trimming tips

P1. SUPPLY TIME – START FUEL

There must be sufficient pellets in the cup that one can just

see the top edge of the uppermost holes on the ignition

direction plate, default setting for 75 seconds (each flash

corresponds to 15 seconds).

P2. FIRING SUPPLY

Default setting for 3 seconds, corresponds to 12 kW at 8

mm pellets and a screw angle of 45º.

P3. FAN OVERRUN

The time the fan runs after the operating thermostat has

stopped and the photocell has lost light.

Default set for 150 seconds (each flash corresponds to 30

seconds).

P4. OVERRUN PHASE (Burn out time)

Time with 25% supply since the photocell has seen light

(25% supply of set value on P2).

Default set for 270 seconds (each flash corresponds to 45

seconds).

P5. Photocell sensitivity (Factory set, should normally

not be adjusted).

Check points after installation

The flue gas temperature must be checked (normally be-

tween 170–240 °C). In the event of a fault, adjust the flue

gas temperature according to the manual.

Flue gas analysis (with flue gas analysis gauge, e.g. Testo

325M)

Q Flue gas temp. 170–240 °C

If the flue gas temp. is too high, the amount of surplus

air is too great. In the event of low temperatures, check

the boiler's turbulators if the boiler is equipped with

them. These can be removed or cut off if necessary.

Q CO2-content 10–12%

Q CO ppm 500 and less

Q Air surplus (h-value) 1.7–2.4

Preferably less than 2 for the fuel economy and effi-

ciency to be satisfactory.

Q O2-content 8–11%

Q Efficiency 80% and more

Combustion efficiency

Q Vacuum in boiler

15–20 Pa (1.5–2 mm Vp)

Readings taken from inside the boiler's flue connection

5–6 Pa (0.5–0.6 mm Vp)

Readings taken in fireplace area

Remarks: These values can be used as good starting

values for a new boiler.

On an older unsealed boiler the supply air can be above 3.

The vacuum in the fireplace must be at least 5–6 Pa.

Tip:

A flame from a match or similar can be used to check the

seal of the doors on the boiler.

If any of the doors has a leak, the flame is drawn towards

the boiler. If the fan damper is choked at installation on an

unsealed boiler in order to obtain ideal values according

to the table, cooling the photocell may not be sufficient

whereupon the it may melt.

It may be necessary to make compromises for an older

unsealed boiler.

Commissioning and adjusting

LD1 P3

P5

P4

P2P1LD2LD3

Loading...

Loading...