ENGLISH – 9

CloseOpenSbSStop

Bluebus

1 2 3 4 5 6 7 8 9

10 11 12

L1

L2

S

11

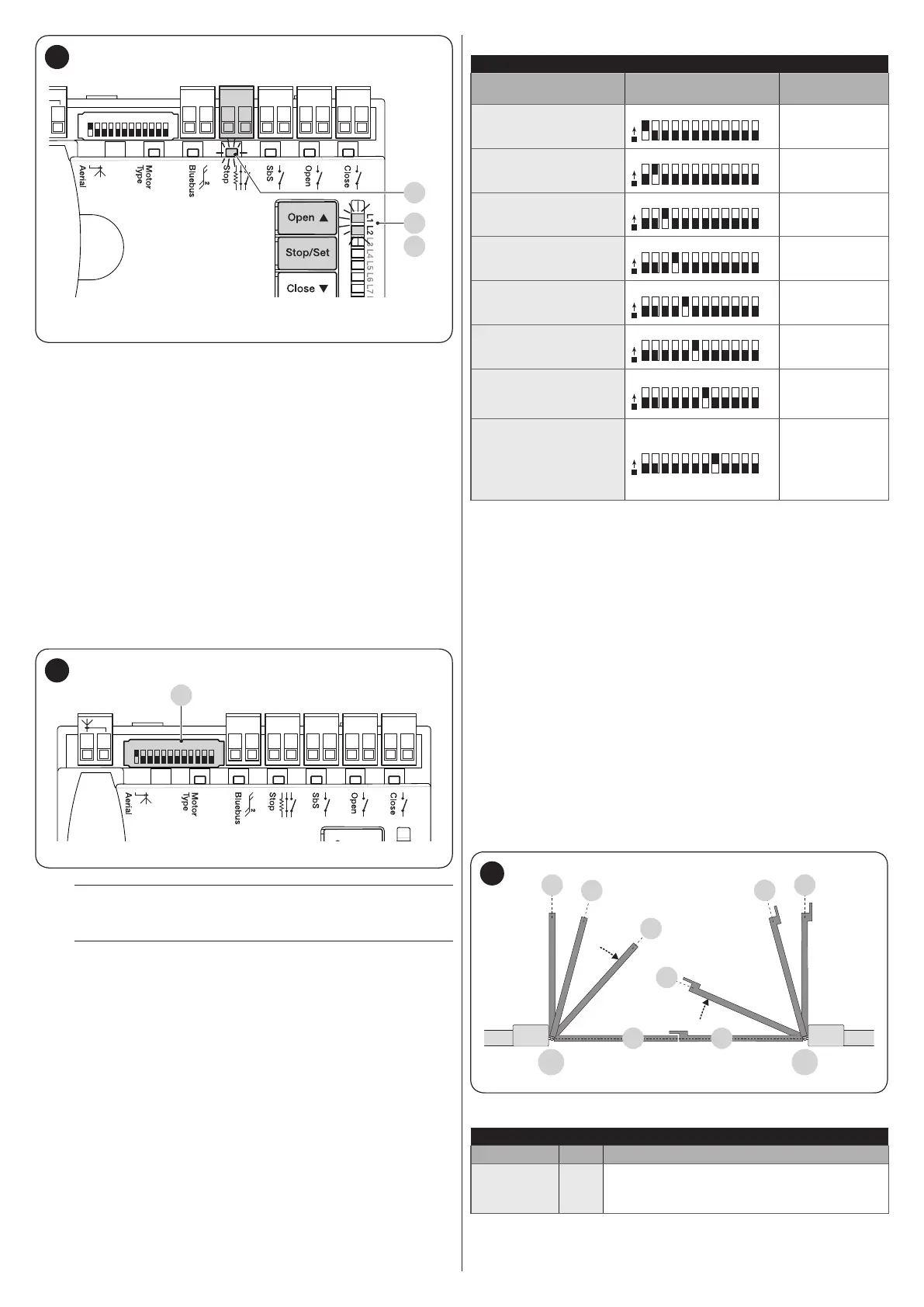

LEDs “L1” and “L2” on the control unit (“Figure 11”) emit some

slow ashes to signal that the learning procedure must be car-

ried out.

To do this:

1. simultaneously press and hold the

f

and

g

buttons

2. release the buttons when LEDs “L1” and “L2” start ash-

ing quickly (after roughly 3 seconds)

3. wait a few seconds until the control unit has completed the

device learning phase

4. once this phase terminates, the “Stop” (S) LED must be lit

and LEDs “L1” and “L2” must switch off (LEDs “L3” and

“L4” could start ashing).

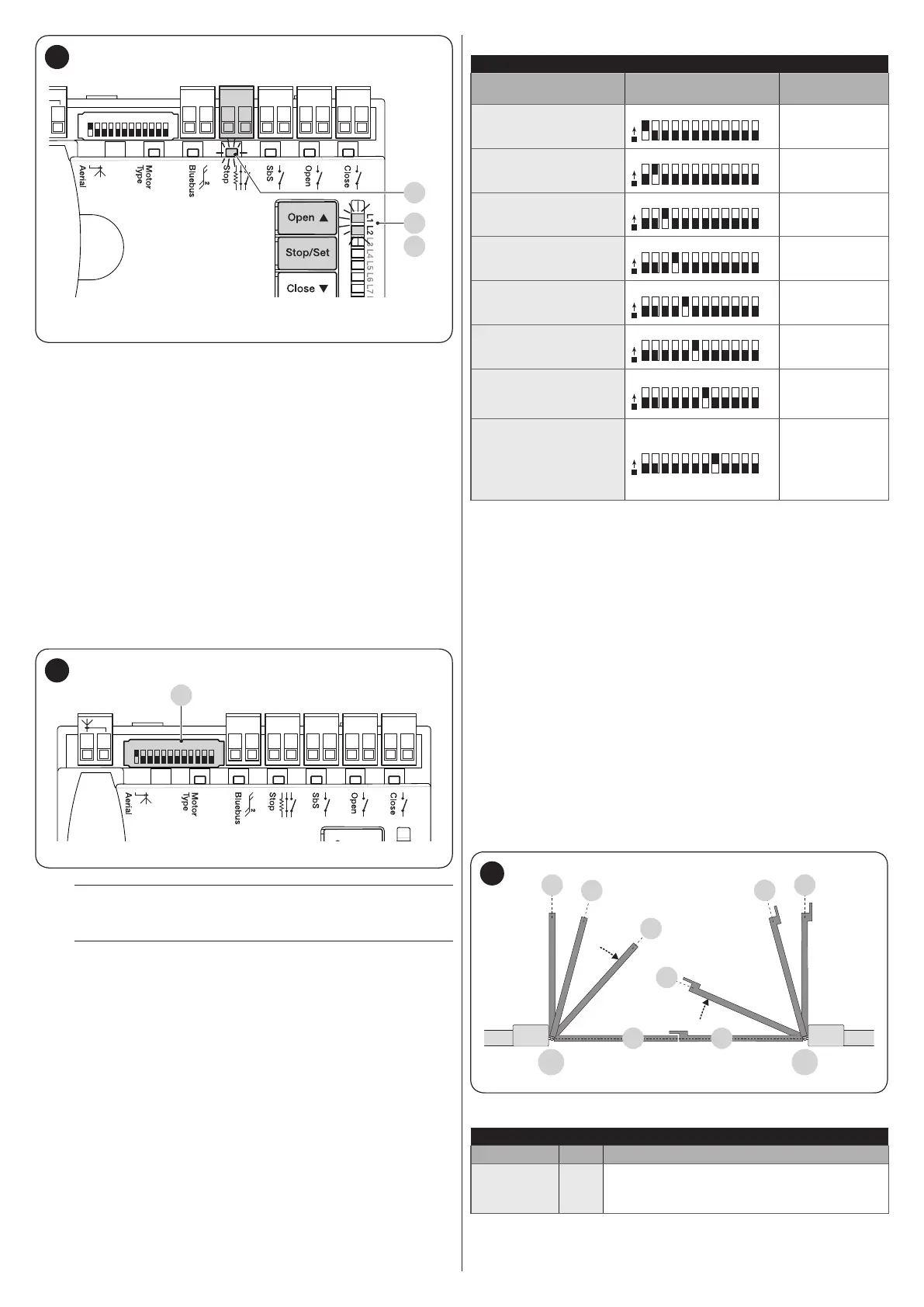

4.7 MOTOR SELECTOR

The control unit is equipped with a selector (A - “Figure 12”) that

allows for specifying which type of motor to use (see “Table 4”).

CloseOpenSbSStop

Bluebus

1 2 3 4 5 6 7 8 9

10 11 12

A

12

m

The motor selector must be set before activating

the mechanical stop learning function.

m

Any conguration not appearing in “Table 4” is not

allowed.

Table 4

SELECTING THE MOTOR TYPE

Motor type Motor selector

Visualisation on

Oview

MB4024 - MB5024 -

HY7024 - HY7124

O

N

MB4024

MFAB3024

O

N

ME3024

TO4024 - XFAB2124 -

LFAB4024

O

N

TO4024

TO5024 - TO5024I

O

N

TO5024

TO7024 - TO6024HS

O

N

TO7024

BFAB5024

O

N

BM5024

METROELITE

- MFAB3024HS -

TO5024HS

O

N

METROE

WINGOELITE

- WG3524HS -

LFAB4024HS

- TTN3724HS -

TTN6024HS

O

N

WINGOE

4.8 LEARNING OF THE MECHANICAL STOP

POSITIONS

Once the connected devices have been learned, the mechan-

ical stop positions must be learned (maximum opening and

maximum closing). This procedure can be carried out in three

different ways: automatic, manual and mixed.

In automatic mode, the control unit learns the mechanical stops,

calculates the most appropriate gate leaf offsets and calculates

the slowdown points “SA” and “SC” (“Figure 13“).

In the manual mode, the positions (“Figure 13”) are programmed

one by one, by shifting the leaves to the desired points. The po-

sition to be programmed can be identied when one of the eight

LEDs “L1...L8” ashes (see “Table 5“).

In the mixed mode, it is possible to perform the automatic pro-

cedure and then, with the manual procedure, modify one or

more positions with the exception of the “0” and “1” positions,

which correspond to the mechanical stop positions.

1 1

M1 M2

0 0

SC

SA

A

A

13

Table 5

PROGRAMMING POSITIONS

Position LED Description

Position 0

(motor 1)

L1

maximum closing position: when the leaf

relative to motor 1 strikes the closing

mechanical stop

Loading...

Loading...