Exclusion position (0xa4)

This parameter is expressed in seconds and can be set with a value from 0 to 300 seconds; the factory setting is 50 seconds. Note – the “0” setting is con-

sidered the fully closed position of the automation. This function enables the programming of the maximum limit, over which the control unit automatically

disables the inversion manoeuvres envisaged in the obstacle detection functions, if the latter are active.

FOTO exclusion position (0xaf)

This parameter is expressed in seconds and can be set with a value from 0 to 4000 seconds; the factory setting is 0 seconds. Note – the “0” setting is con-

sidered the fully closed position of the automation. This function programs the maximum limit within which the control unit automatically inhibits monitoring

of the photocells (FOTO address).

Position compensation (0xfc)

• automatic compensation (0x97)

This parameter is ON/OFF; the factory setting is “OFF”. This function is useful if using a 8K2 resistive type or OSE optical type sensitive edge. The function

enables recovery of the extension of metal ropes of the automation usually caused by wear over prolonged operation. If the sensitive edge trips at the fully

closed position, the control unit will stop the motor a few encoder pulses (compensation value) earlier the next time the door is closed.

• compensation value (0x2e)

This parameter can be set with a value from 0 to 20; the factory setting is “2”. This parameter enables programming of a number of encoder pulses on the

control unit, required for the “position compensation” function. This parameter is only effective if the parameter “automatic compensation” is active (ON).

Work time (0xa7)

Sets the maximum duration of the manoeuvre. When it times out, the manoeuvre is aborted.

• mode

❒ manual: in this mode, the work time is taken from the congurable parameter “maximum work time”.

❒ automatic: in this mode, the control unit measures the time taken to complete the manoeuvre after position learning, and sets a slightly higher value.

• maximum time

This parameter ranges from 0 to 120s, and represents the maximum time within which a manoeuvre must be completed in the manual mode; the default

value is 60s.

❒ value 1: opening time

❒ value 2: closing time

Advanced parameters

INPUT conguration

This item covers the commands available and associable with inputs 1-2-3 present on the control unit of an automation. The commands available for each

input are described in Table 1; while the command categories and relative operating modes are described in Tables 1a, 1b, 1c etc. Important – For correct

operation of the control unit, the command programmed on an input must be associated with the corresponding command category and lastly the required

operating mode.

For congure an input, proceed as follows:

01. In the section “Advanced parameters” select the item “input conguration” and then the input to be programmed. Select the command and conrm with

“OK”.

02. Then, still in ”Advanced parameters”, select “command conguration” and select the category of the command selected in step 01. Finally, select the

operating mode. There are three available inputs:

• Input 1

This programs Input 1, by assigning a command from among those listed in Table 1. Input 1 is factory set to “step-by-step” command, with the “Industrial

Mode” operating mode for sectional doors – with “open - stop - close - open” mode for high-speed doors.

• Input 2

This programs Input 2, by assigning a command from among those listed in Table 1. Input 2 is factory set to “open”, “opening” category and “open-stop-

open” mode.

• Input 3

This programs Input 1, by assigning a command from among those listed in Table 1. Input 3 is factory set to “close” command, with the “Industrial Mode”

operating mode for sectional doors – with “open - stop - close - open” mode for high-speed doors.

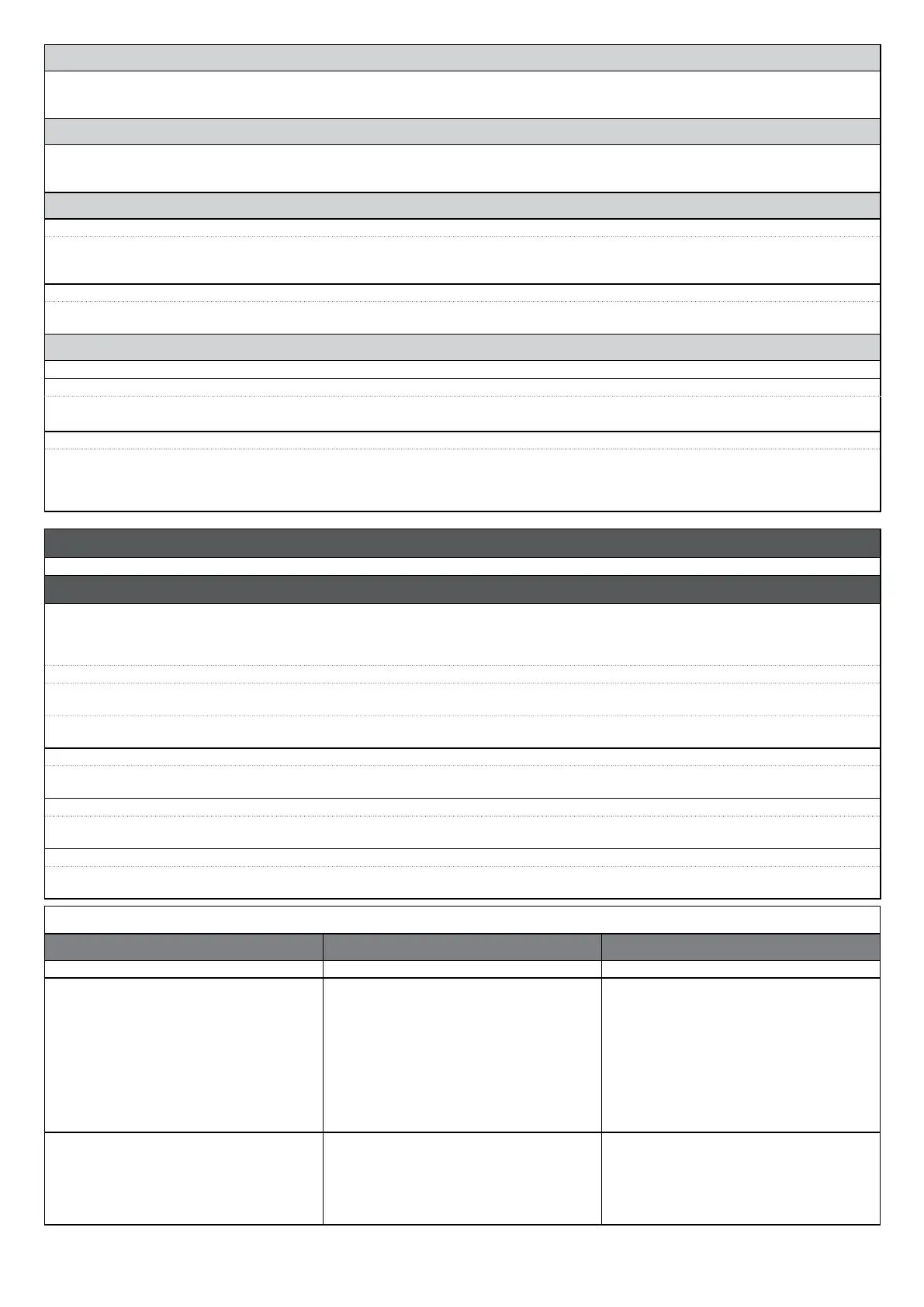

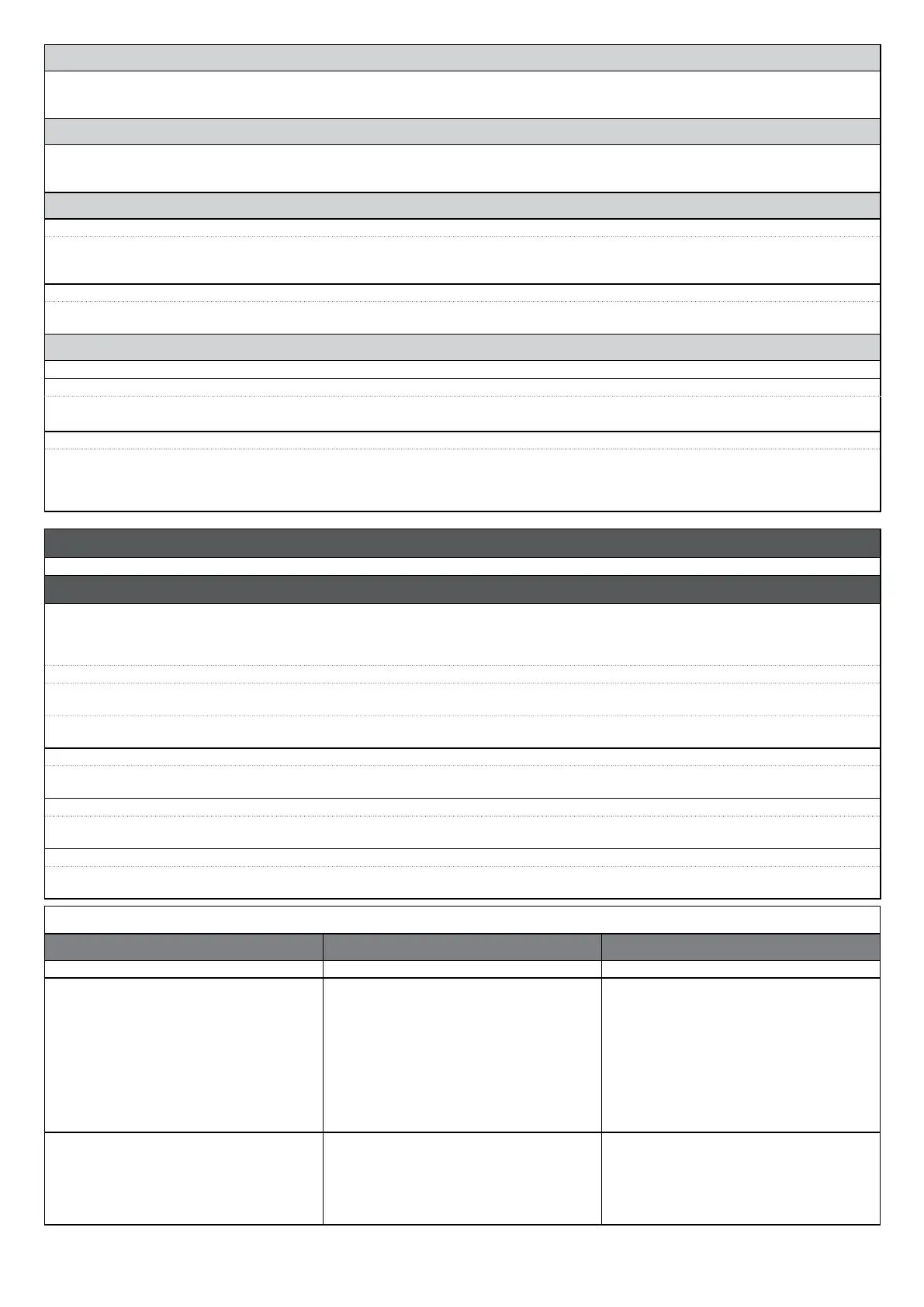

TABLE 1: INPUT CONFIGURATION

COMMAND COMMAND CATEGORY DESCRIPTION

No command Does not perform any command.

Step-by-step Step-by-step Program the desired mode from

those given in Table 1-A (“Command conguration”

> “step-by-step” > operating mode ...)

The command is factory assigned to Input 1, with

the “Industrial Mode” operating mode for sectional

doors – with “open - stop - close - open” mode for

high-speed doors.

When the command is sent, the control unit

makes the automation run the manoeuvre follow-

ing that previously (or still) in execution, according

to the order of manoeuvres given in the pro-

grammed sequence. Input congured as normally

open.

Partial open 1 Partial open Program the desired mode from those

listed in Table 1-B (“Command conguration” >

“partial open” > mode ...)

When this command is sent the control unit acti-

vates the application to complete the Opening ma-

noeuvre until the position is reached as set in the

function “partial open 1”(Control unit functions >

installation > positions > partial open 1). Input con-

gured as normally open.

Loading...

Loading...