Operator’s manual

Optima 51 / M51 / M56 / M57T / 60T

39

Dynapôle Ludres/Fléville, 166 rue Ampère/BP 60093 - 54714 LUDRES - FRANCE - Tél.+33 (0)3 83 25 69 60 - Fax. +33 (0)3 83 26 12 85

7. Removal

As for all work, observe the safety instructions.

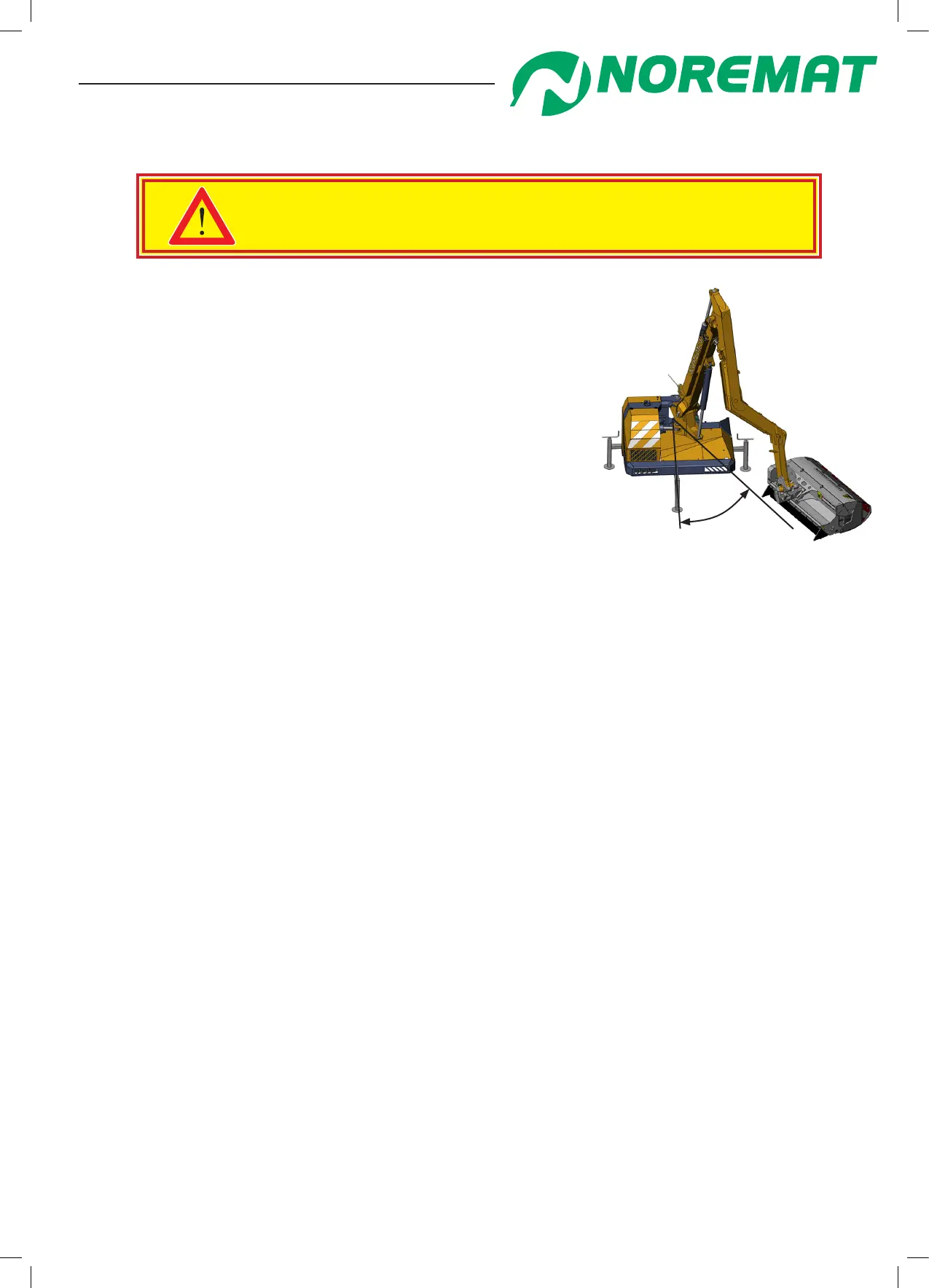

45°

gure 2.20

-It is important to choose a site where the ground is at and rm

and there is no risk of the machine sinking due to rain.

- In order to make the machine stable in removal move the arm to

45 degrees to the centreline of the frame (gure 2.20) and lower

the tool to the ground.

- Disengage the PTO and select ‘neutral’ on the PTO

engagement control. Switch of the engine of the tractor/cv.

- Relieve the pressure in the hydraulic circuit by operating all of

the controls;

- for machines with electric or mixed controls; t the manual lever

at the main block slices and move in both directions

- for machines with Low-Pressure controls, operate the levers then switch off.

For machines equipped with an accumulator, see the discharge procedure

(see chapter 2, paragraph <Operate safely>.

- Place the three parking legs in the supports provided for this purpose.

Adjust the height as required.

Depending on the type of frame used, remove the locking keys, or the mounting hooks, the PTO shaft,

the electric plugs and the control unit plug

-Check the stability of the machine and if satisfactory, drive the tractor/carrying vehicle away slowly.

- Protect the control/console unit against foul weather with the cover provided.

8. Storage

Before doing anything :

- Clean the machine taking care not to aim the high pressure water jet at electrical components

(electric box, electric valves etc). ATTENTION :Cleaning should only be carried out

with the rotor stopped.

- Operate all cylinders to remove water from the chrome rods.

The following operations should only be carried out with the machine completely at rest :

- Complete greasing of the machine (see chapter 2 paragraph <greasing>);

- Choose a suitable dry place to remove the machine;

- Remove the machine (see preceding paragraph);

- Coat the cylinder rods with grease (Remove before next use);

- Protect the control unit in a safe dry place.

If a hydraulic component has to be removed (valve block, hoses etc ) it is important that in order to

prevent contamination entering the system, all ports and ttings are plugged.

The life-expectancy of the machine depends on the cleanliness of the hydraulic circuit.

Operation and maintenance

Loading...

Loading...