Operator’s manual

Optima 51 / M51 / M56 / M57T / 60T

45

Dynapôle Ludres/Fléville, 166 rue Ampère/BP 60093 - 54714 LUDRES - FRANCE - Tél.+33 (0)3 83 25 69 60 - Fax. +33 (0)3 83 26 12 85

11. Oil changes

ATTENTION

Fluid at high pressure (In the case of our machines, hot oil) can cause serious burns to the body, even

through clothes.

Any oil remaining from leaks or oil changes can cause serious environmental damage.

Take appropriate action to prevent this.

Before commencing any oil changes and to avoid burns, allow the oil to cool to tepid (less than 50

degrees C) before draining it.

See also the paragraph «Contact with oil» in General Safety Rules.

11 1Recommendationsaboutoilchanges

We recommend draining the oil when it is tepid because any contamination present will be ushed out

with it.

It is essential for the correct operation of the machine that the oil and lter changes are carried out in

absolutely clean conditions.

11 2Rotorandmovementhydrauliccircuitoilchanges

ATTENTION

Before starting the oil change, lower the tool to the ground.

First oil change at 300 hours and every 1500 hours afterwards.

At least, at the beginning of every season.

Oil tank capacity : 70 litres of oil, NOREMAT HV46 (ref: 108 357)

Park the machine on level at ground.

Procedure :

- clean the area around the ller cap and remove the cap.

- prepare and place a container capable of holding more than

70 litres of oil under the drain plug.

- remove the plug on the underside of the tank and allow to drain

for several minutes.

- ret and tighten the plug. (Do not over-tighten) Wipe off

any oil spills.

- ll the tank, preferably through a ltered funnel.

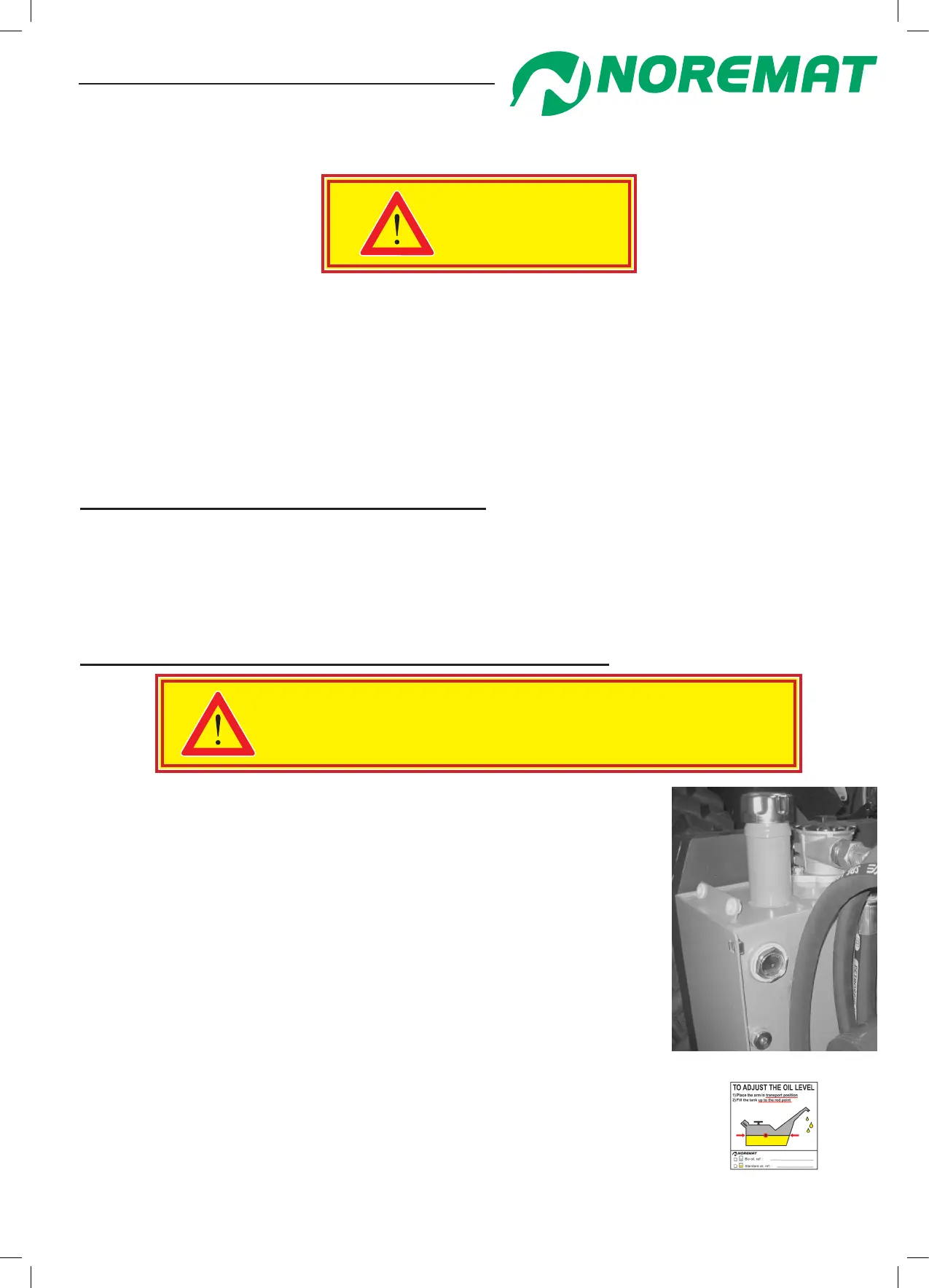

- check the oil level in the tank. (See the decal opposite on your machine ).

- replace the ller cap and wipe off any further spillages.

gure 2.28

Operation and maintenance

Loading...

Loading...