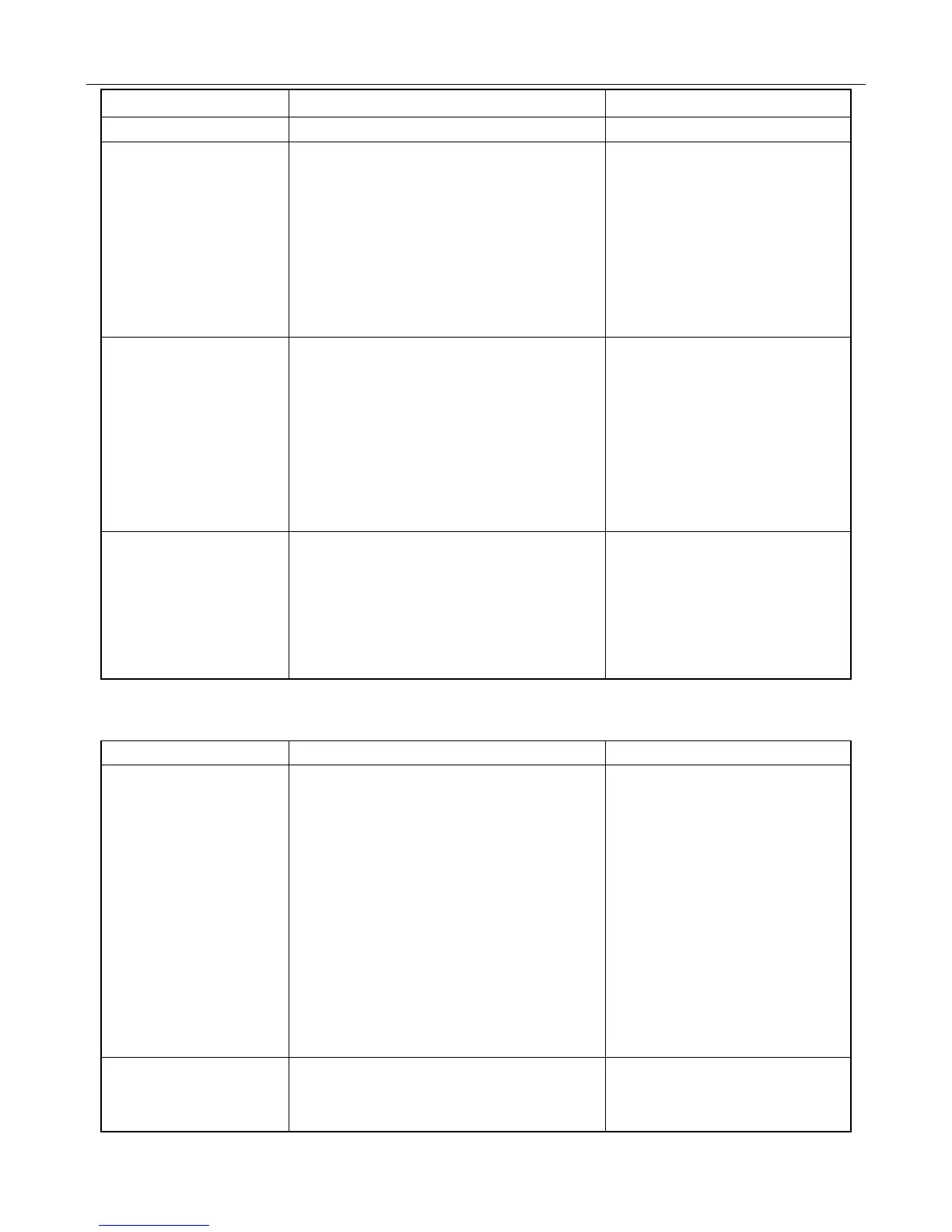

Operation Description

43

Gearshift disengages

automatically

(1) The gearshift interlocking rod is too short

(2) The locating slot of the shifting fork shaft

is severely worn

(3) The spring pressure of the interlocking

latch is insufficient

(4) The bearing on the gear shaft is worn,

making the shaft tilt

(5) The spline of the tooth holder is worn

(1) Lengthen the gearshift

interlocking pull rod

(2) Replace the shift fork

(3) Adjust or replace the

interlocking pin spring

(4) Replace the bearing

(5)Replace the tooth holder

(1) The shift lever fork is worn

(2) The gear guide plate is severely worn

(3) The fork slot of the shifting fork and the

meshing bush are worn

(4) Locating pin of interlocking pin and shift

fork is severely worn

(1) Repair or replace the

shift lever

(2) Replace the gearbox

guide plate

(3) Replace the shifting fork and

the meshing bushing

(4) Replace the interlocking pin

and the shift fork shaft

Noise or impact sound

from the gear box

(1) The gear is excessively worn and/or the

tooth surface has chipped off

(2) The bearing is badly worn or damaged

(3) The lubricating oil is insufficient or

oil quality does not conform to

the specifications

(1) Replace the gear

(2) Replace the bearing

(3) Fill or replace lube oil

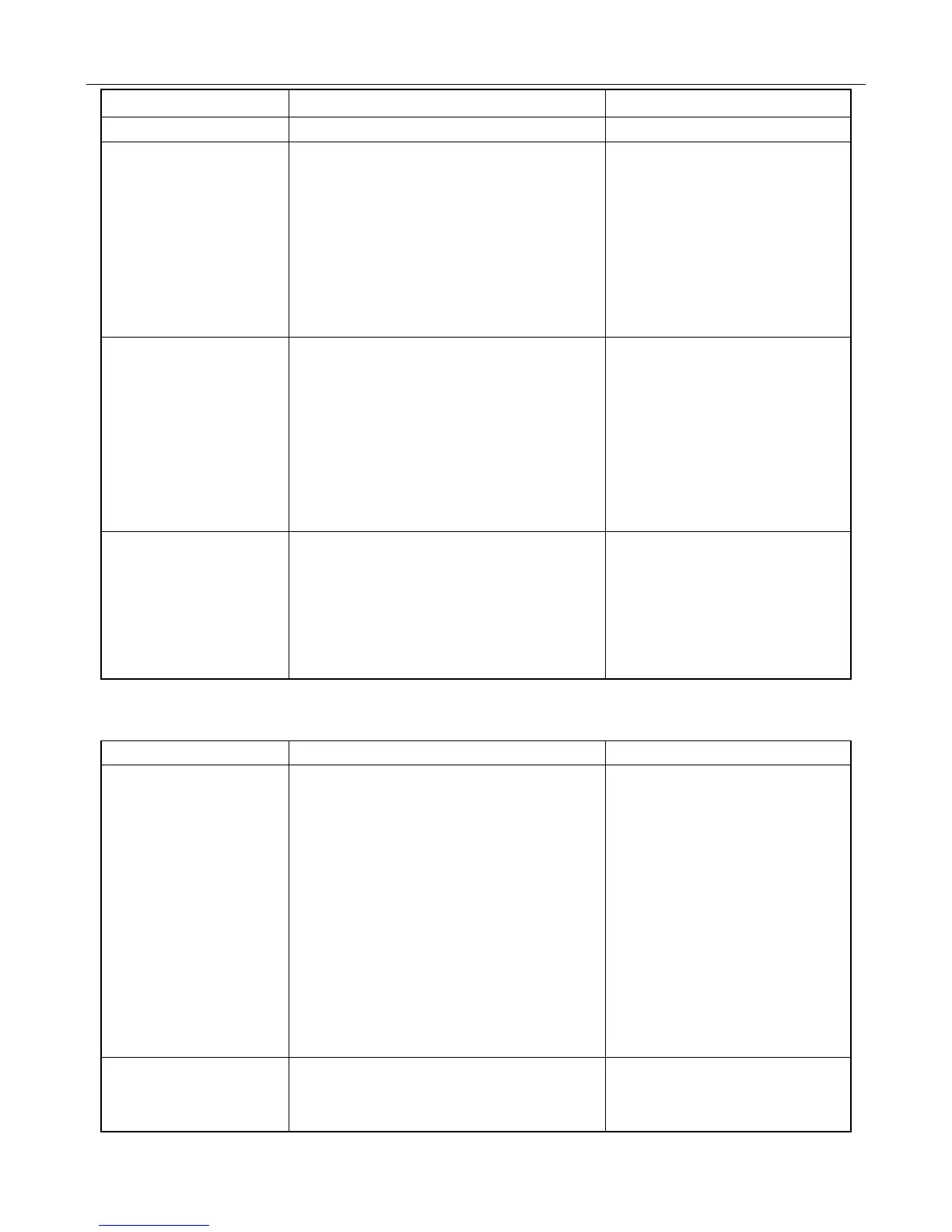

2.18.1.3 Rear Axle Faults and Brake Faults Troubleshooting (Table 2-4)

Table 2-4 Rear Axle Faults and Troubleshooting

Increased noise in the

central drive

(1) The bearing play of the small conical gear

is too large

(2) Gear engagement is abnormal

(3) The bearing of the conical gear pair or the

gear pair is damaged

(4) The differential shaft is worn or locked

(5) The planetary gear or gasket is worn

(6) The differential bearing is worn

or damaged

(1) Adjust according

to requirements

(2) Readjust according

to requirements

(3) Replace the bearing or

the gear

(4) Replace the differential

gear shaft

(5) Replace the planetary gear

or gasket

(6) Replace the

differential bearing

Small conical gear

and the differential

bearing overheat

(1) The pre-load force is too high

(2) Poor lubrication

(3) Backlash at gear pair side of conical gear

(1) Readjust the pre-load force of

the bearing

(2) Check the lubricating oil level

Loading...

Loading...