Operation Description

42

with a 50/50 water/antifreeze blend.

Check the front wheel toe-in and free play of clutch and brake pedal. Adjust if necessary.

Check and tighten the bolts nuts, and screws that are accessible.

Put grease into every grease fitting.

2.18 Common Faults and Troubleshooting

2.18.1 Chassis Faults and Troubleshooting

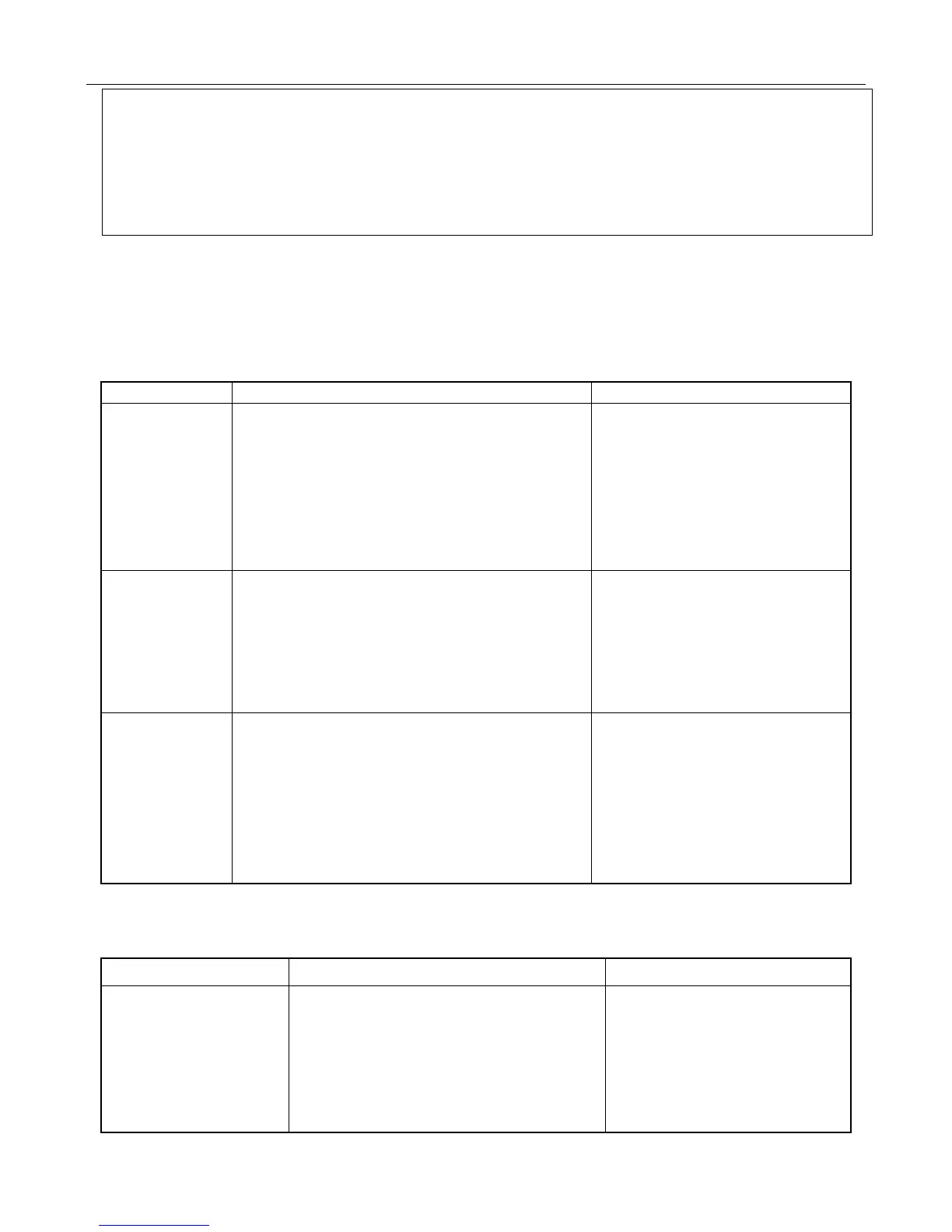

2.18.1.1 Clutch Faults and Troubleshooting (Table 2-2)

Table 2-2 Clutch Faults and Troubleshooting

(1) The clutch plate and pressure plate are dirty

or greasy

(2) The clutch plate is excessively worn or burnt

(3) The Belleville spring pressure is too low

(4) The free play of the pedal is too small or there is

no free play

(5) The clutch fingers are badly deformed

(1) Clean with solvent. Find the

cause and eliminate the fault

(2) Replace the clutch plate

(3) Replace the spring

(4) Re-adjust the free play of the

pedal according to the specifications

(5) Replace the clutch fingers

The cultch

does not

disengage

completely, and

noise is heard

when it

is engaged

(1) The free play of the pedal is too large and the

working play is too small

(2) The clutch fingers are excessively warped

(3) The heads of the three clutch fingers are not in

the same plane

(1) Adjust the free play of the pedal

according to the specifications

(2) Replace the clutch fingers

(3) Adjust according

to requirements

The tractor

shakes when

starting

(1) The heads of the three clutch fingers are not in

the same plane

(2) The clutch plate and the clutch fingers have

grease on them

(3) The clutch fingers are warped

(4) The fastening screw for the flywheel and the

clutch has come loose

(1) Make adjustments according

to requirements

(2) Clean the friction plate and the

clutch fingers with solvent

(3) Replace the clutch fingers

(4) Stop the tractor immediately and

repair the fault

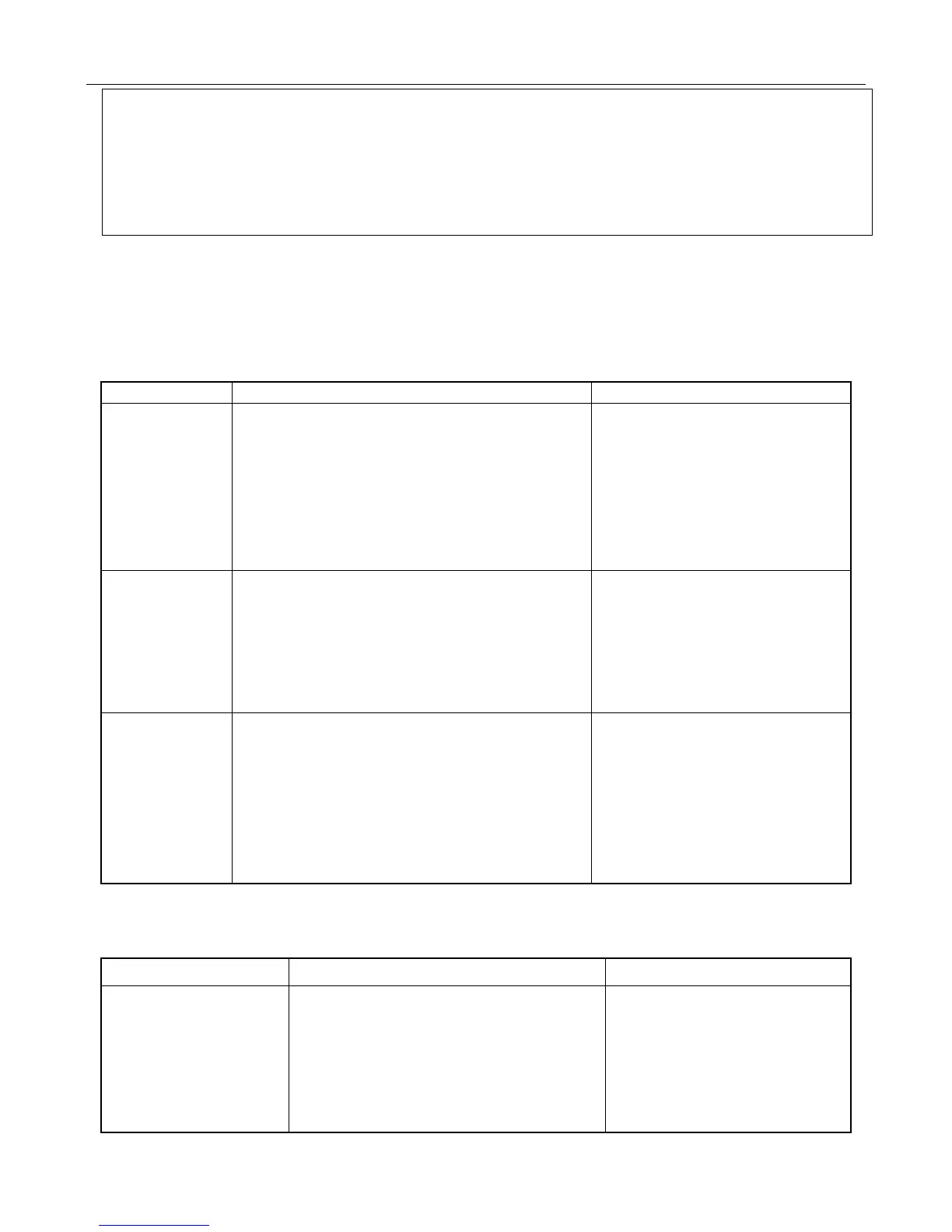

2.18.1.2 Gearbox Fault and Troubleshooting (Table 2-3)

Table 2-3 Gearbox Faults and Troubleshooting

Putting the tractor

into gear is difficult

or impossible

(1) Clutch has not disengaged completely

(2) Gearshift interlocking rod is too long

(3) The shift lever fork is severely worn

(4) The end face of the engagement sleeve or

the end face of the gear is worn or broken

(1) Troubleshoot according to the

clutch type

(2) Shorten the gearshift

interlocking pull rod

(3) Replace the shift lever

(4) Replace or repair

Loading...

Loading...