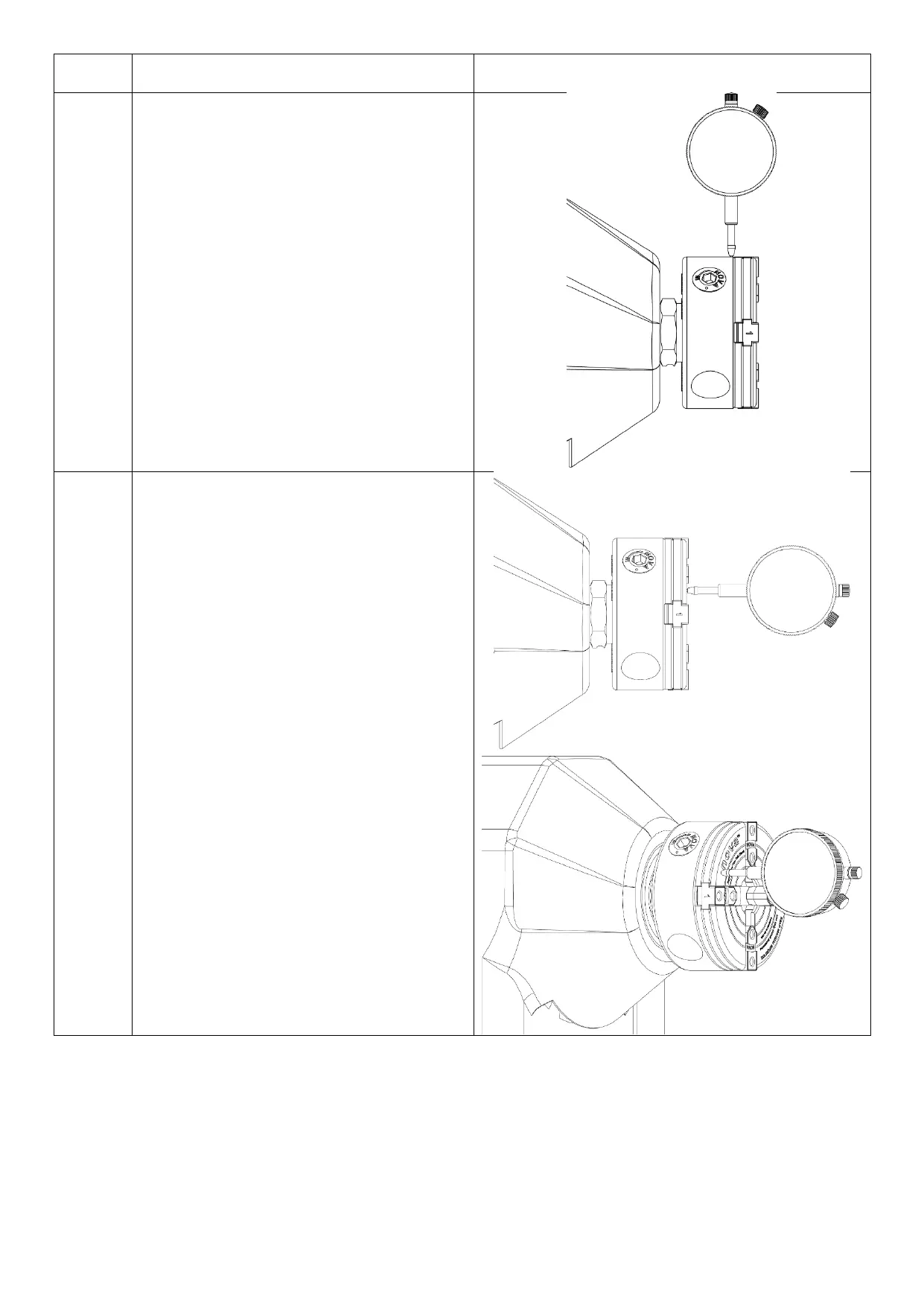

Measure the radial runout of the

attached faceplate by:

Locate the DTI perpendicular to

the spindle rotation axis as shown

in the image.

Spin lathe by hand.

The runout measurement should

be ranging between:

-0.15mm ~ +0.15mm (±0.006in)

Any reading exceeding this value

will be exceeding the standard

tolerances.

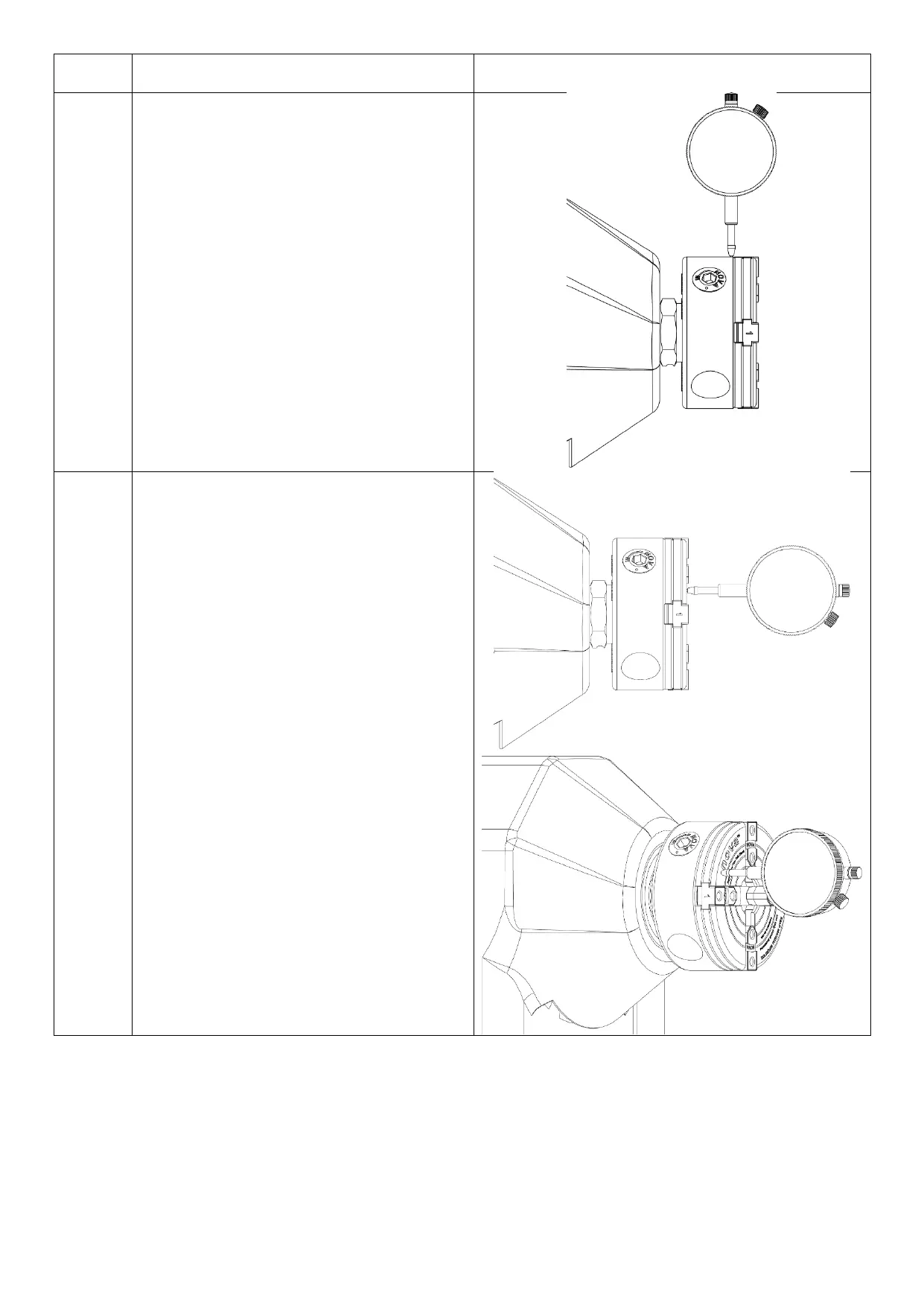

Measure the axial runout of the

attached tool by:

Locate the DTI in the position

shown in the image.

Spin lathe by hand.

The runout measurement should

be ranging between:

-0.08mm ~ +0.08mm (±0.0031in)

Any reading exceeding this value

will be exceeding the standard

tolerances.

Another view of dial indicator

location on face of chuck.

Loading...

Loading...