Installation and Operation Instructions Matrix

Operation and Set-up

The Matrix employs a pneumatic modulation system. This modulation system increases or decreases the velocity

of the combustion blower, to meet the demand for heating. The gas valve senses this change in blower pressure

and introduces the required amount of gas to ensure correct combustion. The (Red) Boiler Controller reads the

boiler water temperature, compares it to the set point, and adjusts the burner firing rate accordingly by varying the

speed of the combustion blower.

The (Blue) Fan Controller communicates the appropriate demand and temperature set point to the (Red) Boiler

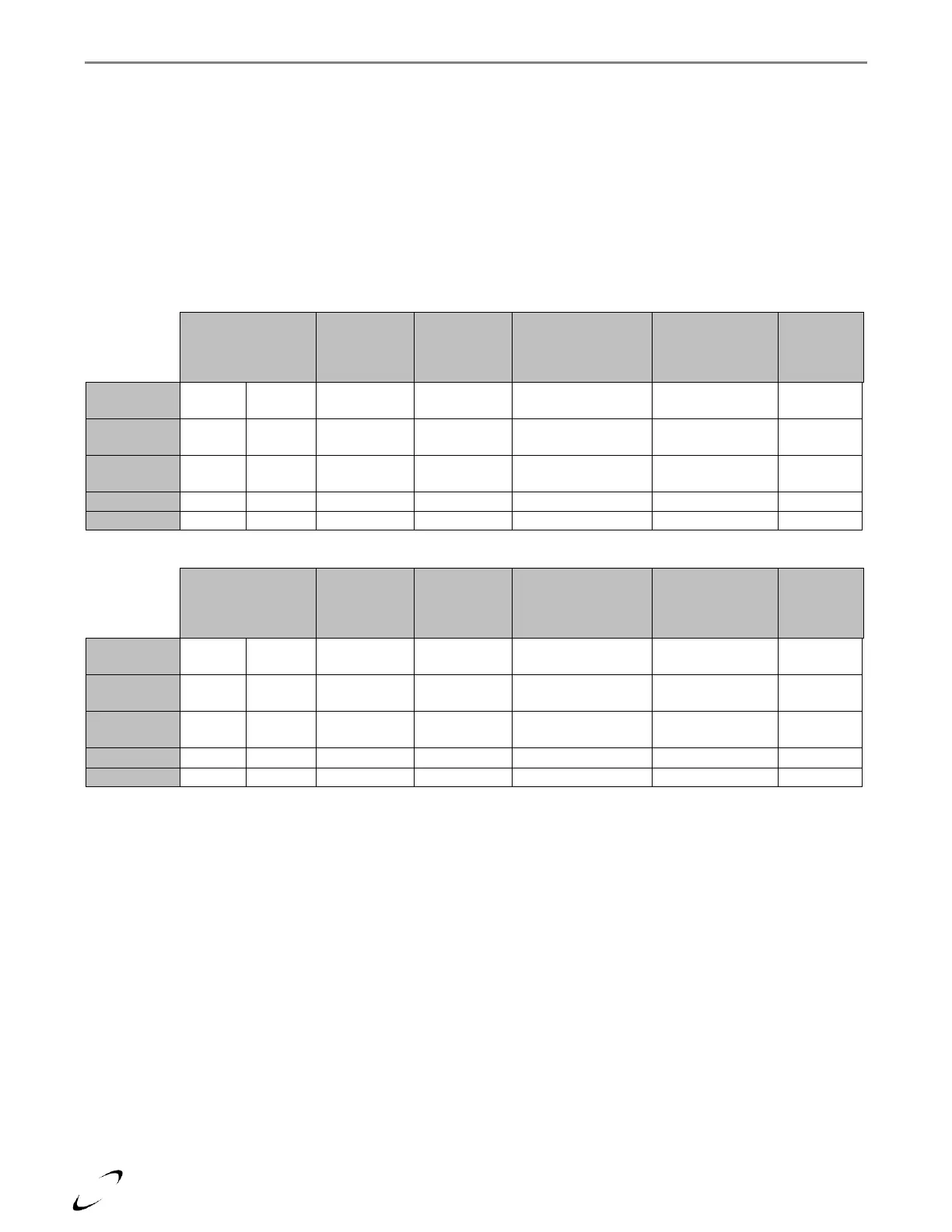

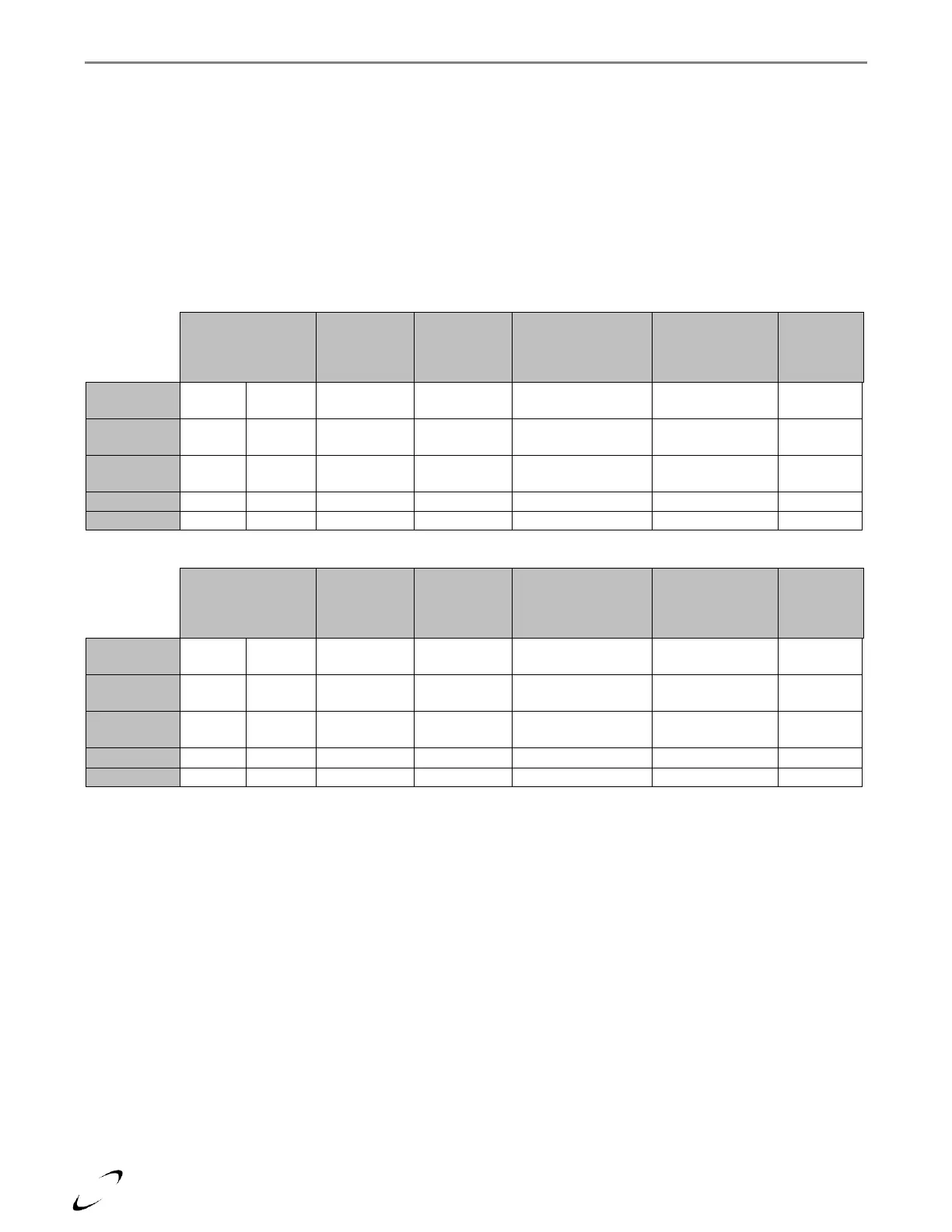

Controller via a series of digital and analog inputs. Tables 13-3(a) and 13-3(b) show the Boiler Controller’s

response to each demand. For more information on ‘RESET MODE’ see section “Outdoor Sensor (10K)”.

Table 13-3(a) Operation – Conventional Mode

Primary

Forced Air

Call (W1)

Auxiliary

Forced Air

Call (W2)

Shared Call

Forced

Air/Hydronic

Greater of SP/ HI

and HYD

Table 13-3(b) Operation – Reset Mode

Primary

Forced Air

Call (W1)

Auxiliary

Forced Air

Call (W2)

Shared Call

Forced

Air/Hydronic

Greater of SP/ HI

Calc.

and HYD

Calc.

Greater of SP/ HI

Calc.

and HYD

Calc.

Note 1: SP (Setpoint) received from Matrix Fan Controller.

Loading...

Loading...