Lx Series Installation and Operation Instructions │Trinity Lx

9

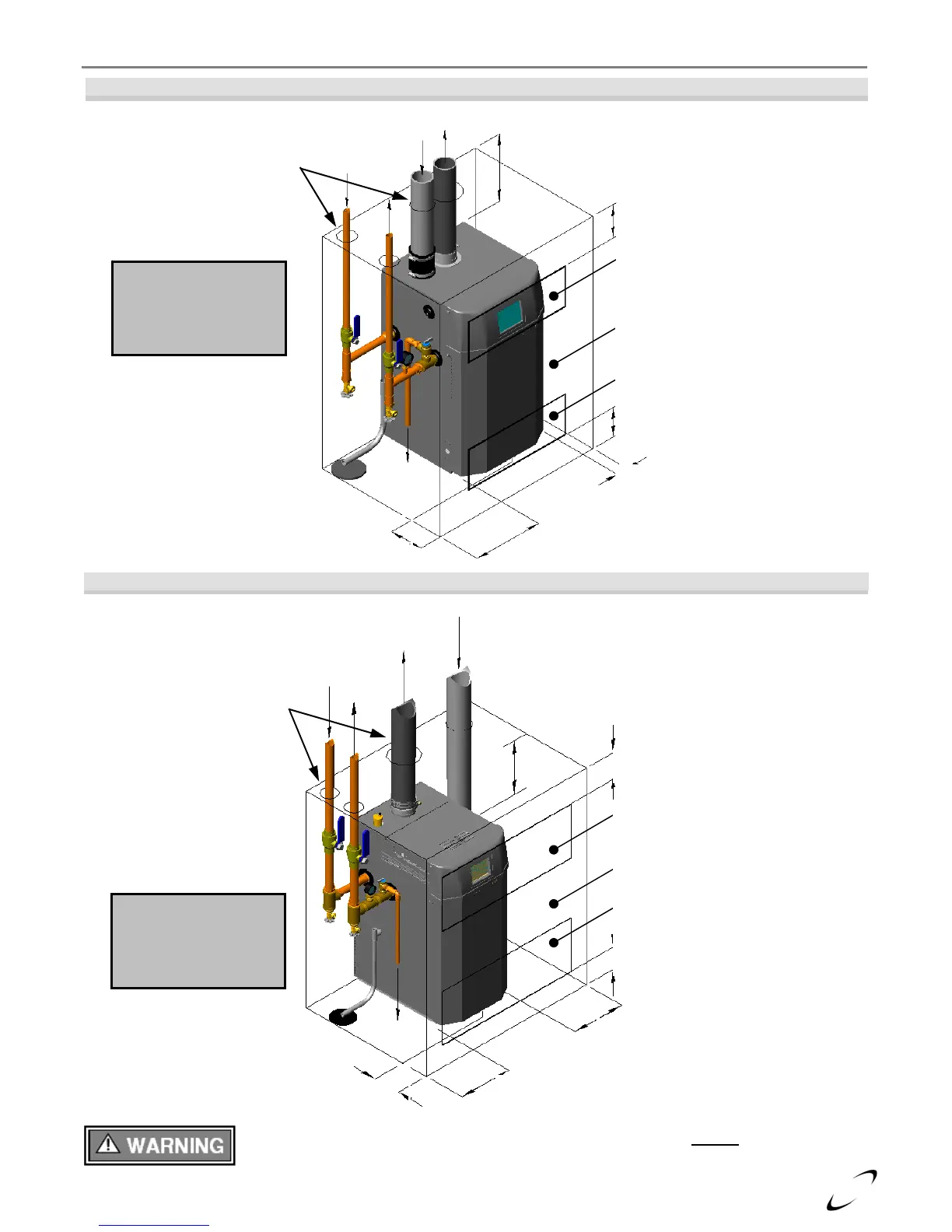

Figure 3-1(a) Lx150-200 Models

Closet Installation, Minimum Clearances

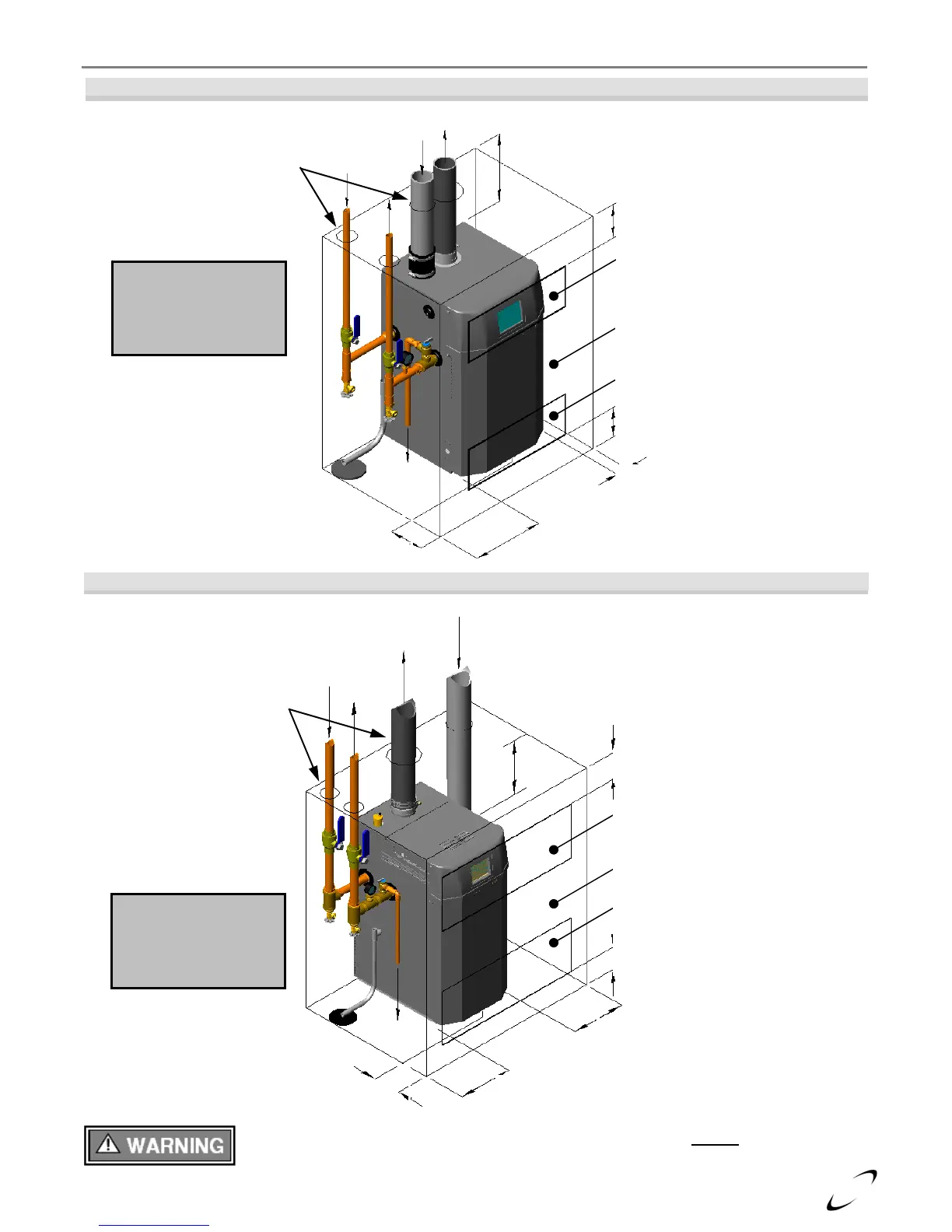

Figure 3-1(b) Lx300-400 Models

Closet Installation, Minimum Clearances

Closet/alcove installations in US and Canada require approved CPVC vent and air-inlet

pipe, fittings, cements and primers (Table 4-3).

Ventilation Air Openings

are not required if the

appliance area meets

the listed Recommended

Clearances in Table 3-1.

Top 12” [305 mm]

6” [152 mm] max. above vent opening

Front 6” [152 mm] - Boilers

Front 36” [915 mm] - Water Heaters

Left Side 12” [305 mm]

Right Side 12” [305 mm]

6” [152 mm] max. below vent opening

Ventilation Air Opening

1 in

2

per 1000 Btu/hr, min. 100 in

2

Ventilation Air Opening

1 in

2

per 1000 Btu/hr, min. 100 in

2

Removable Surface or Closet Door

Piping must be CPVC

1” [25 mm] clearance for

hot water and vent pipes

Ventilation Air Openings

are not required if the

appliance area meets

the listed Recommended

Clearances in Table 3-1.

Top 12” [305 mm]

Removable Surface or Closet Door

Ventilation Air Opening

1 in

2

per 1000 Btu/hr, min. 100 in

2

Ventilation Air Opening

1 in

2

per 1000 Btu/hr, min. 100 in

2

6” [152 mm] max. above vent opening

6” [152 mm] max. below vent opening

Right Side 4” [102 mm]

Left Side 12” [305 mm]

Front 6” [152 mm] - Boilers

Front 36” [915 mm] - Water Heaters

Piping must be CPVC

1” [25 mm] clearance for

hot water and vent pipes

Loading...

Loading...