Trinity Lx │Installation and Operation Instructions Lx Series

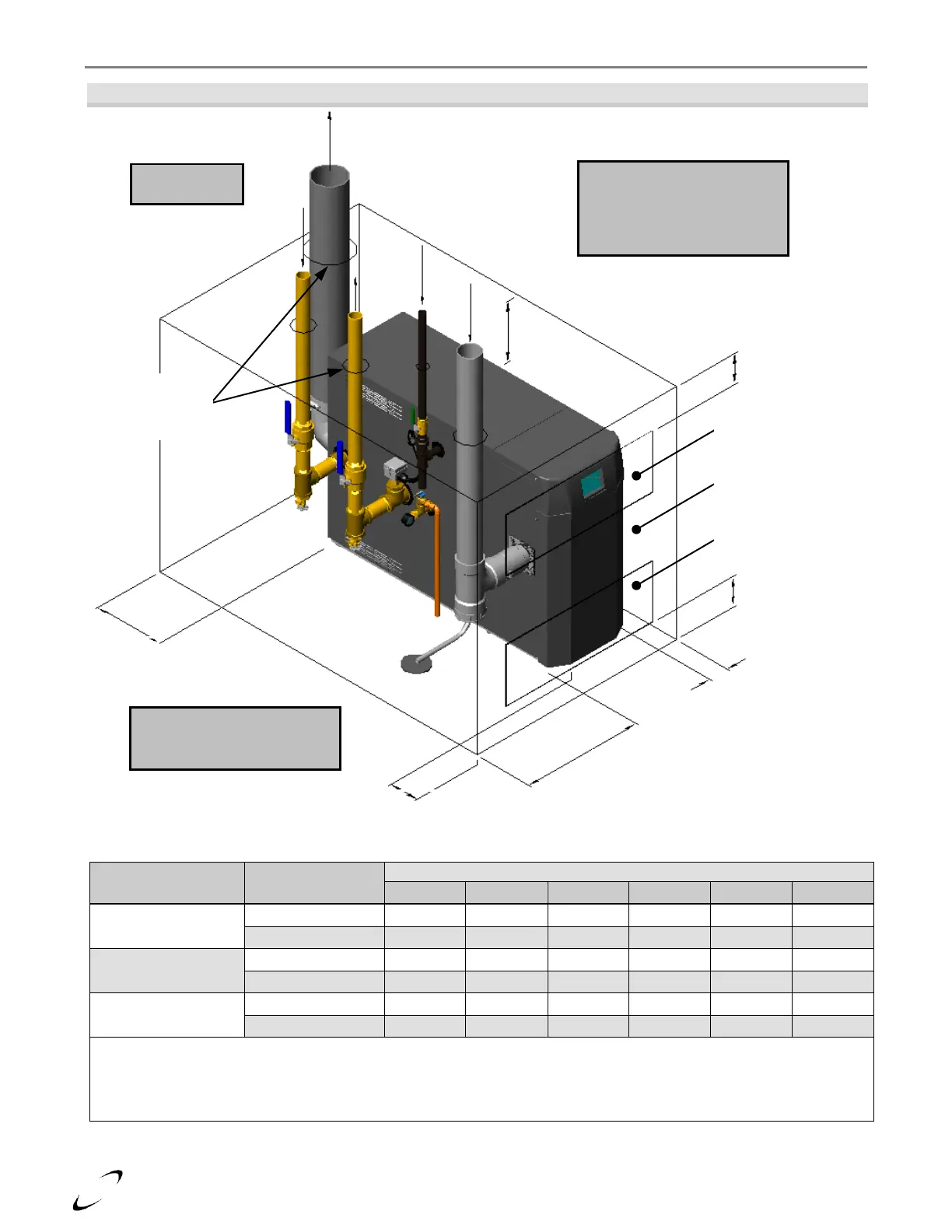

Figure 3-1(c) Closet Installation, Minimum Clearances (Lx500-800)

Table 3-1 Minimum Clearances for Installation and Service

Notes:

1

6” if surface is removable allowing 24” clearance (i.e. closet installation). See Ventilation Air Opening dimensions in

Figure 3-1.

2

Clearances can be as low as 12” if the right side has a clearance of 24”.

3

For models Lx500-800, ensure rear of unit is accessible for wiring and flue gas testing.

6” [152 mm]

max. below

vent opening

1” [25 mm]

clearance for

hot water and

vent pipes

6” [152 mm]

max. above

vent opening

Removable Surface

or Closet Door

Ventilation Air Opening

1 in

2

per 1000 Btu/hr,

min. 100 in

2

Ventilation Air Opening

1 in

2

per 1000 Btu/hr,

min. 100 in

2

Ventilation Air Openings -

Openings are not required if

the appliance area meets the

Recommended Clearances in

Table 3-1.

Access - Ensure rear of unit is

accessible for wiring and flue

gas testing. See Table 3-1.

Loading...

Loading...