9

CLEARANCES

To ensure optimal performance a minimum of 30 inches

clearances required from the back, left and right sides of the

HPWH unit and any wall obstruction. A minimum of 36 inches

clearance on the front of the unit for access to the control box.

ELECTRICAL REQUIREMENTS

Ensure the power supply voltage and phase at the job site

matches the power supply ratings listed on the HPWH data

sticker label BEFORE INSTALLATION BEGINS.

The installation must conform with these instructions and the

local code authority having jurisdiction and the requirements

of the power company. In the absence of local codes,

the installation must comply with the current editions of

t he N a tional Electrical Code, ANSI/NFPA 70 or the Canadian

Electrical Code CSA C22.1.

Voltage applied to the HPWH should not vary more than +5%

to -10% of the voltage requirement listed on the HPWH rating

label for satisfactory operation.

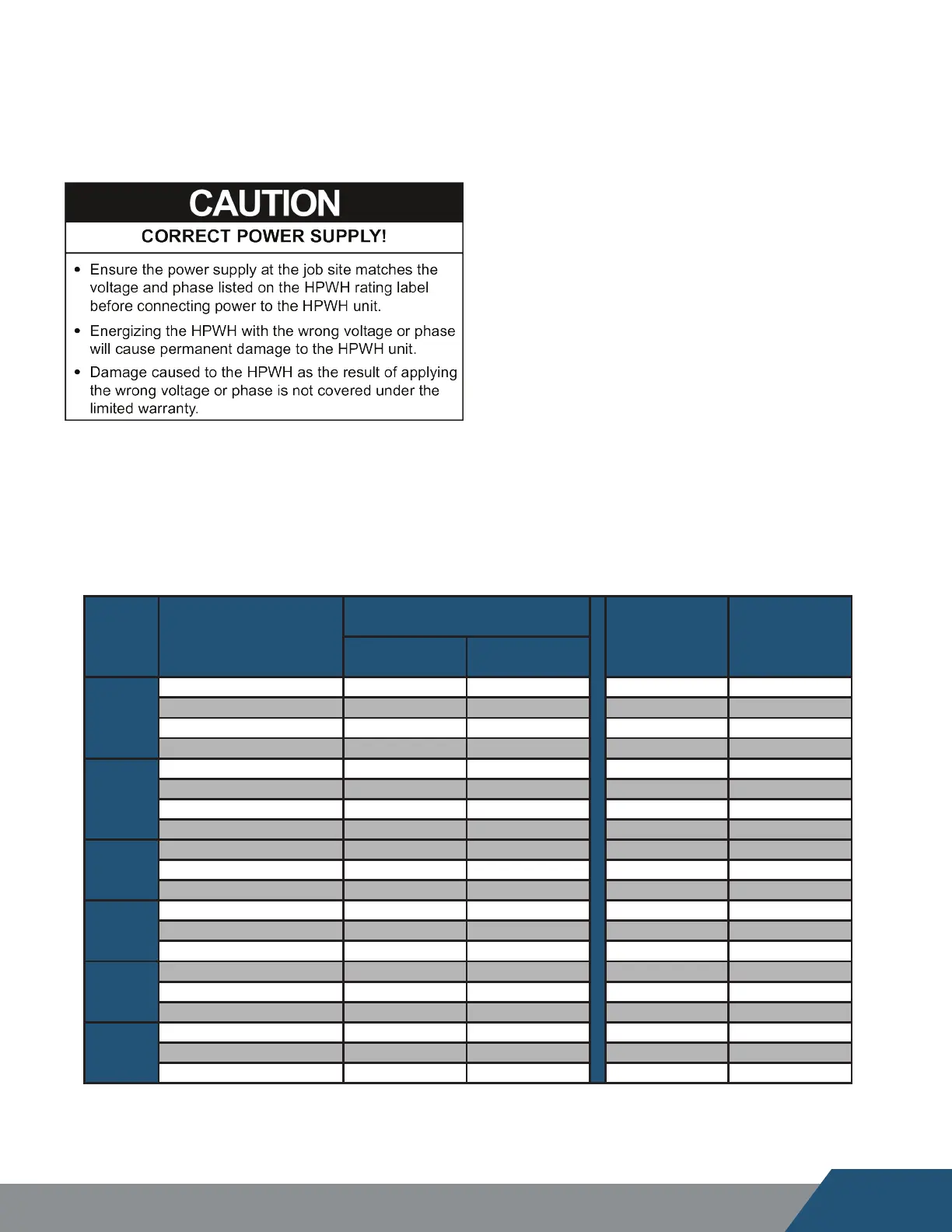

TABLE 2 - VOLTAGE & AMPERAGE RATINGS

Model Volts/Phase/HZ

Compressor

MCA MOCP/MFS

LRA RLA

C25W

208-230/1/60 73 17.4 22 25

208-230/3/60 63 10.4 13 15

440-480/3/60 31 5.9 7 10

575/3/60 31 5.2 7 10

C60W

208-230/1/60 129 30.1 38 40

208-230/3/60 156 22.1 28 30

440-480/3/60 75 11 14 15

575/3/60 54 9 11 15

C90W

208-230/3/60 239 37.2 46 50

440-480/3/60 125 19.8 25 30

575/3/60 80 13.4 17 20

C125W

208-230/3/60 300 53 65 70

440-480/3/60 150 26.7 33 35

575/3/60 109 23.5 29 30

C185W

208-230/3/60 505 78 97 100

440-480/3/60 225 35 43 45

575/3/60 180 29.3 36 40

C250W

208-230/3/60 446 92.7 116 125

440-480/3/60 223 46.7 59 60

575/3/60 164 38.9 49 50

LRA: Locked Rotor Amps RLA: Rated Load Amps

MCA: Maximum Current Ampacity MOCP: Minimum Overcurrent Protection

Loading...

Loading...