11

CLOSED WATER SYSTEMS

Water supply systems may, because of code requirements or

such conditions as high line pressure, among others, have

installed devices such as pressure reducing valves, check

valves, and back ow preventers. Devices such as these cause

the water system to be a closed system.

THERMAL EXPANSION

As water is heated, it expands (thermal expansion). In a closed

system the volume of water will grow when it is heated. As the

volume of water grows there will be a corresponding increase

in water pressure due to thermal expansion. Thermal expansion

can cause premature failure (leakage) of storage tanks, water

heaters and HPWH components such as the condenser. Leakage

caused by thermal expansion is not covered under the HPWH

limited warranty.

Thermal expansion can also cause intermittent Temperature-

Pressure Relief Valve operation: water discharged due to

excessive pressure build up. The Temperature-Pressure Relief

Valve is not intended for the constant relief of thermal expansion.

A properly sized thermal expansion tank must be installed on

all closed systems to control the harmful eects of thermal

expansion. Contact a local plumbing service agency to have a

thermal expansion tank installed on all closed water systems.

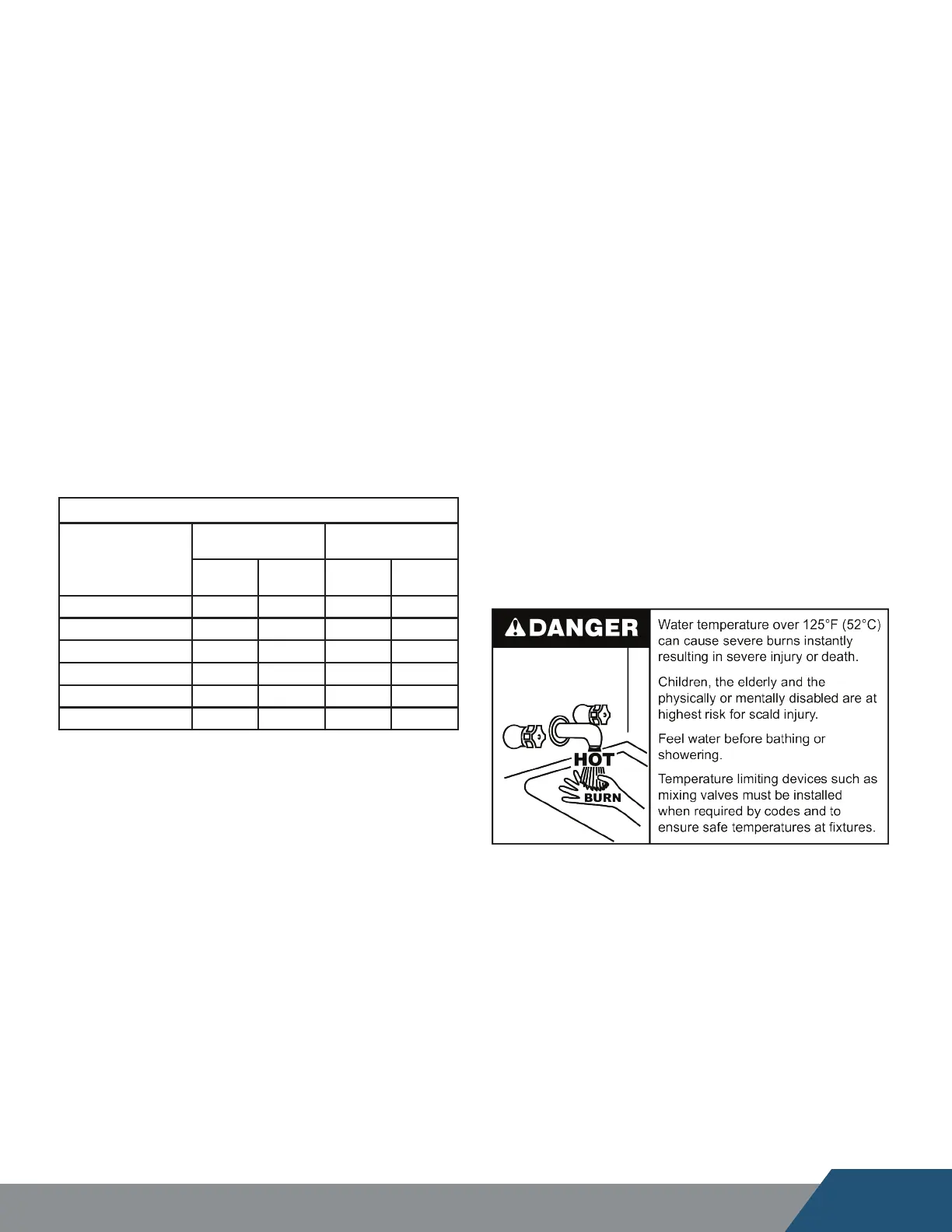

MIXING VALVES

Water heated to a temperature which will satisfy clothes washing,

dish washing, and other sanitizing needs can scald and cause

permanent injury upon contact. See Table 5, page 12.

Some people are more likely to be permanently injured by

hot water than others. These include the elderly, children, the

inrm and the physically/mentally disabled. The Table below

shows the approximate time-to-burn relationship for normal

adult skin. If anyone using hot water provided by the water

heater being installed ts into one of these groups or if there is

a local code or state law requiring a certain water temperature

at the point of use, then special precautions must be taken.

In addition to using the lowest possible temperature setting

that satises the demand of the application a Mixing Valve

should be installed upstream from the building xtures or at

the hot water taps to further reduce system water temperature.

WATER PIPING

Read all installation requirements in this manual before

installation begins.

The water piping installation must conform to these instructions

and to all local and national code authority having jurisdiction.

Costs to diagnose, perform service and repair damage caused

by installation errors are not covered under the limited warranty.

Costs to correct installation errors are not covered under the

limited warranty.

MINIMUM PIPE SIZE

The inlet (return) and outlet (supply) water piping installed be-

tween the HPWH unit and the storage tank must not be smaller

than the water connection sizes on the HPWH. See Table 4, be-

low, for water line connection sizes and water ow rates.

Water line sizing is a critical installation requirement. Installing

undersized water piping between the storage tank and the

HPWH unit will cause insucient water ow and will have an

adverse impact on performance and equipment life.

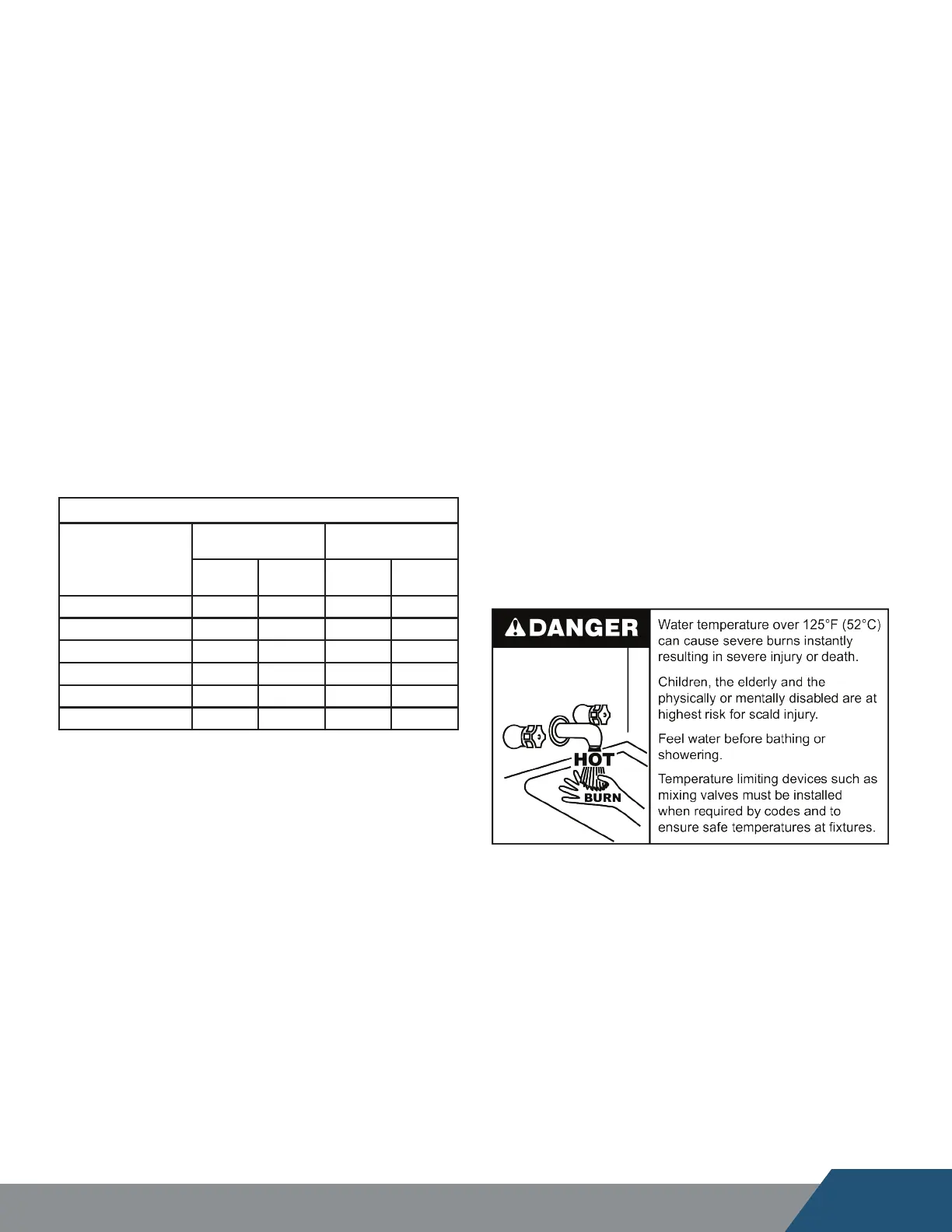

TABLE 4

PIPE SUPPORT

All water piping must be properly supported per local code

requirements.

PIPE INSULATION

All piping installed between the HPWH unit and the storage

tank must be insulated.

COLD WATER SUPPLY

Cold water supply lines should not be connected directly to

the HPWH inlet or T tted into the inlet (return) water piping.

The cold water supply lines should be connected directly to

the storage tank only. See Inlet & Outlet Water Temperature

on page 8 and Figure 7 and Figure 8 on page 16.

WATER PRESSURE

System water pressure should be maintained between 40 and

60 PSI. Local code may require, and the manufacturer recommends,

installing a pressure reducing valve (PRV) in the cold water

supply to the building to maintain consistent water pressure

.

Water Connection and Flow

Unit

Water Flow Rate

(GPM)

Connection Size

(Inches)

Single

Pass

Multi

Pass

Single

Pass

Multi

Pass

C25W

2.5 5.4 ¾” ¾”

C60W

6 13 1” 1”

C90W

9 20 1” 1½”

C125W

12.5 25 1” 1½”

C185W

18.5 40 1½” 2”

C250W

25 50 1½” 2”

Loading...

Loading...