27

CHECK WATER TEMPERATURE RISE

Always check water temperature rise through the HPWH

unit’s internal heat exchanger before checking the refrigerant

charge. See Start Up on page 19 for information on how to

measure the water temperature rise.

If the measured water temperature rise during start up was

within 8°F to 12°F (4°C to 7°C) checking the charge is not

necessary unless other conditions warrant testing.

If the measured temperature rise through the HPWH unit is

less than 8°F (4°C) checking the charge is not necessary

unless other conditions warrant testing. Short water piping

runs between the HPWH and the storage tank will produce

lower temperature rises and are not problematic.

If the measured temperature rise through the HPWH unit is more

than 12°F (7°C) check for restrictions in the inlet and outlet water

piping connected between the HPWH unit and the storage tank.

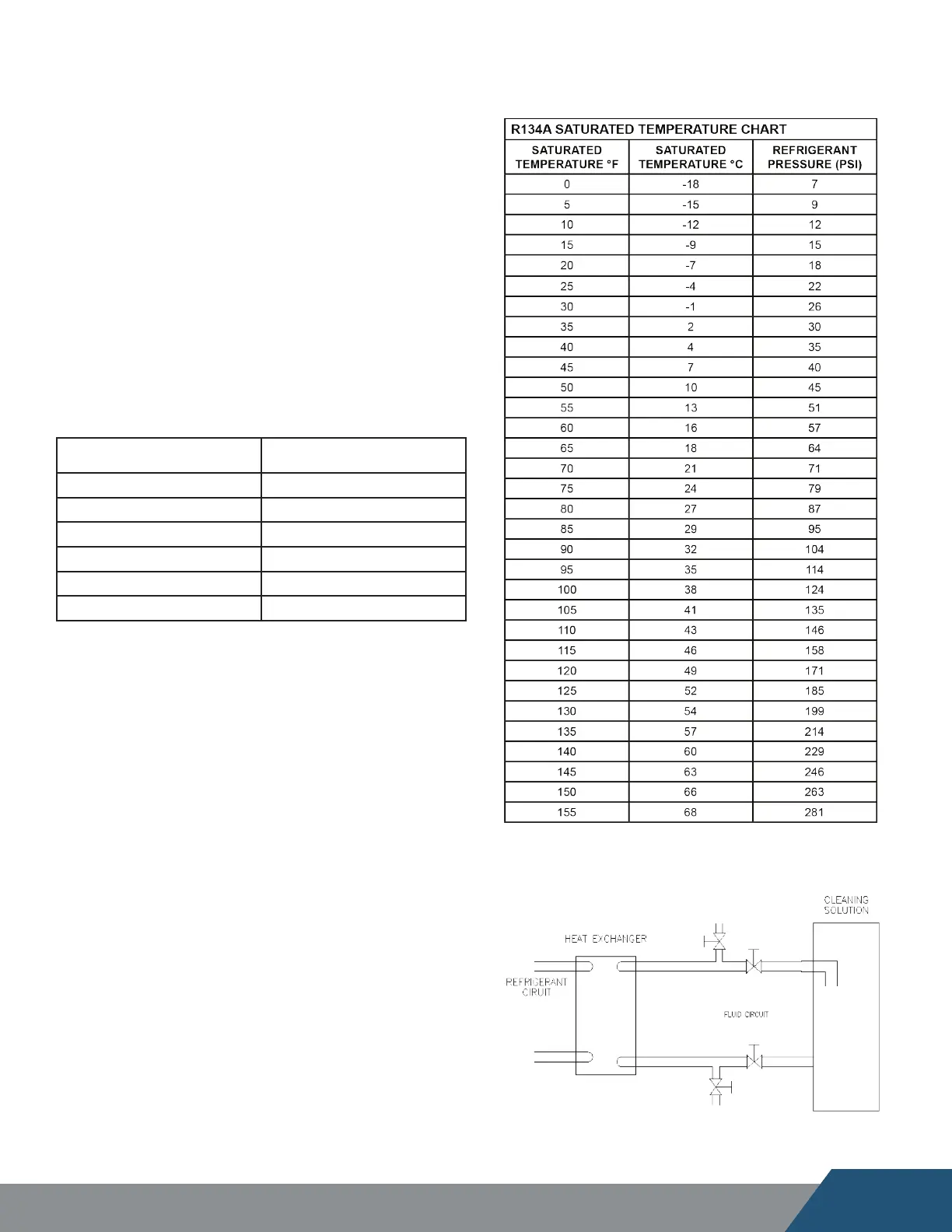

TABLE 9

SUPERHEAT CALCULATION

1. Measure and record the suction pressure at the

suction line pressure access port inside the unit.

2. Convert the recorded suction pressure to saturated

temperature.

3. Measure the suction line temperature near the suction

line pressure access port inside the unit.

4. Compare the suction line temperature to the saturated

temperature in Table 10.

5. The difference between saturated temperature and

suction line temperature is the superheat. Superheat

normal range should be 8°F to 12°F (4.4°C to 6.7°C)

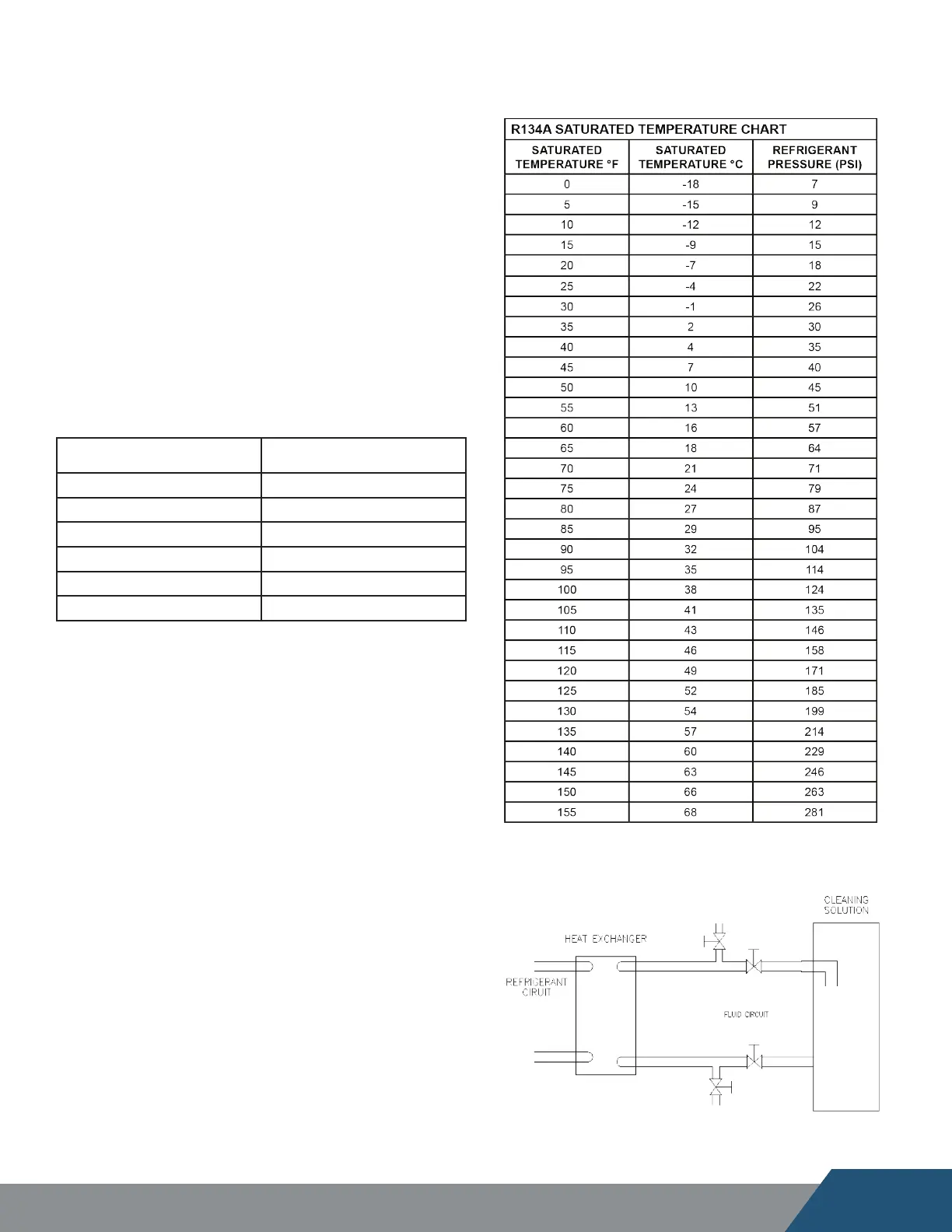

BRAZE PLATE CLEANING INSTRUCTIONS

In some applications the heat exchanger may be subjected

to severe uid conditions, including high temperature hard

water conditions, causing accelerated scaling and corrosion

rates, and will diminish performance.

It is important to establish regular cleaning schedules, A 5%

solution of Phosphoric Acid or Oxalic Acid may be considered.

Other types of solutions can be obtained from your local

wholesaler. Make sure cleaning solution is applicable for stainless

steel and copper and all directions are followed.

Do not heat solution. Be sure to ush heat exchanger with

fresh water after cleaning. See Figure 12.

Model Factory Charge R134A

C25A 7 #

C60A 14 #

C90A 21 #

C125A 25 #

C185A 30 #

C250A 50 #

TABLE 10

FIGURE 12

Loading...

Loading...