OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ote.com 9

Lubricity Test

The Lubricity Test should only be performed when the unit has been

successfully calibrated with deionized water and gives a Coefcient of

Friction reading of 34 ± 2. See page 24.

1. Clean the lubricity test ring (#111-02-01 with a at outer surface) and the

lubricity test block (#111-08-01 with a concave groove on one side) with

acetone and rinse both thoroughly with deionized water. All parts of the

machine in the sample area (block holder and shaft) must be completely

clean before starting a test.

Do not touch the metal contact areas with bare hands.

Removing the ring from the main shaft can change the alignment of the

contact area with the block. We recommend removing the ring only to

replace it (along with the block) or to switch between lubricity and extreme

pressure tests.

The Coefcient of Friction for water is 34 ± 2 at 60 rpm and 150

inch-pounds. Since not all metallurgical structures are the same nor is

the contact area the same between the metal parts, a variance of ± 2 is

allowed. When calculating the Coefcient of Friction, a correction factor of

34 divided by the water reading is used. A test should never be performed

if the Coefcient of Friction for water is outside this range.

2. Place the lubricity test ring squarely onto the tapered portion of the main

shaft. Secure the test ring retainer nut with a " wrench. Make sure the

ring seats squarely on the taper of the shaft.

3. Turn on the power and let the machine run for approximately 15 minutes.

4. Place the lubricity test block in the block holder with the concave side

facing out away from the torque shaft. Do not let the ring and block

contact each other.

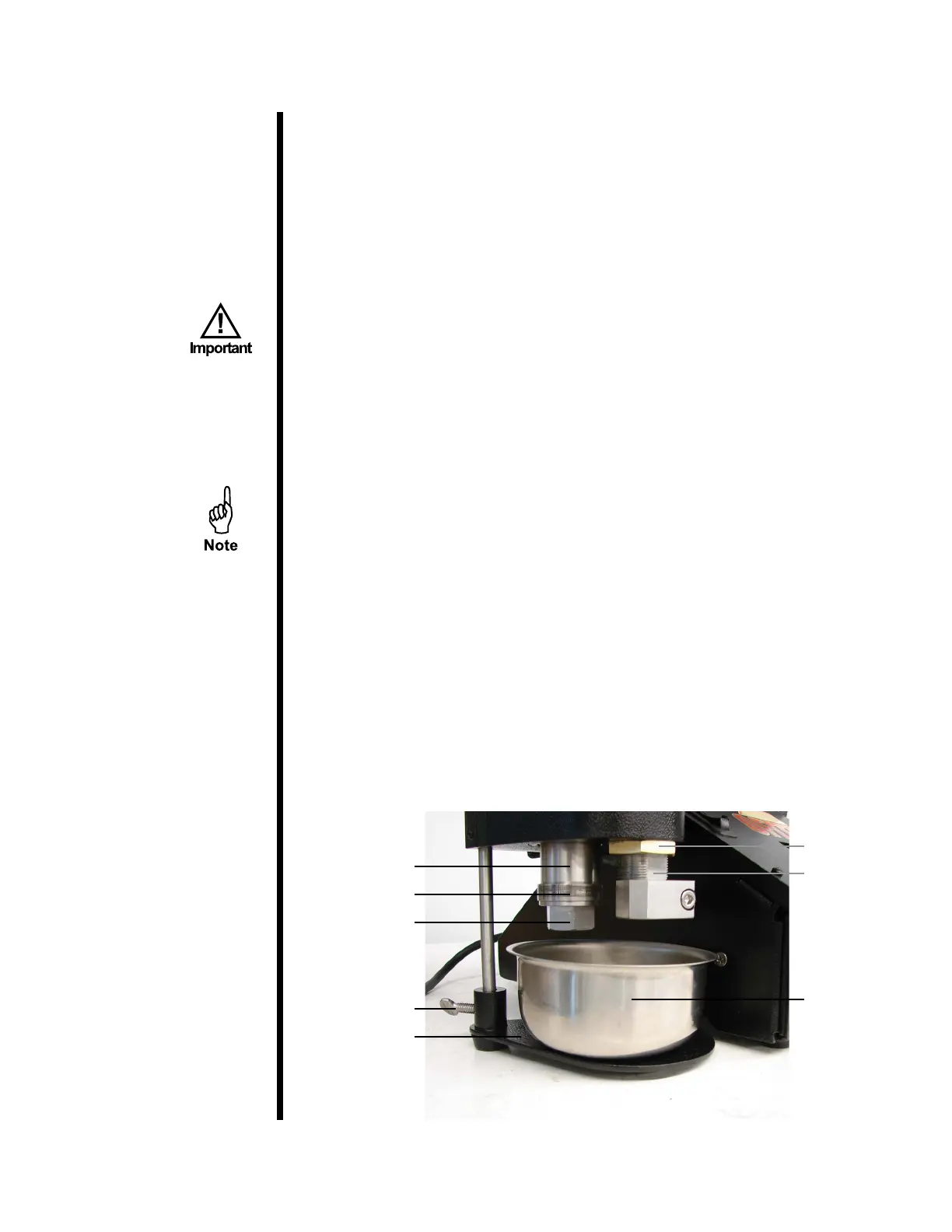

Torque Bushing

(#111-00-36)

Sample Cup

(#111-09)

Locking Nut

(#111-00-009)Main Shaft

(#111-00-34)

Test Ring

Retainer Nut

(#111-00-35)

Thumb Screw

(#141-18)

Cup Stand

Loading...

Loading...