OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ote.com 24

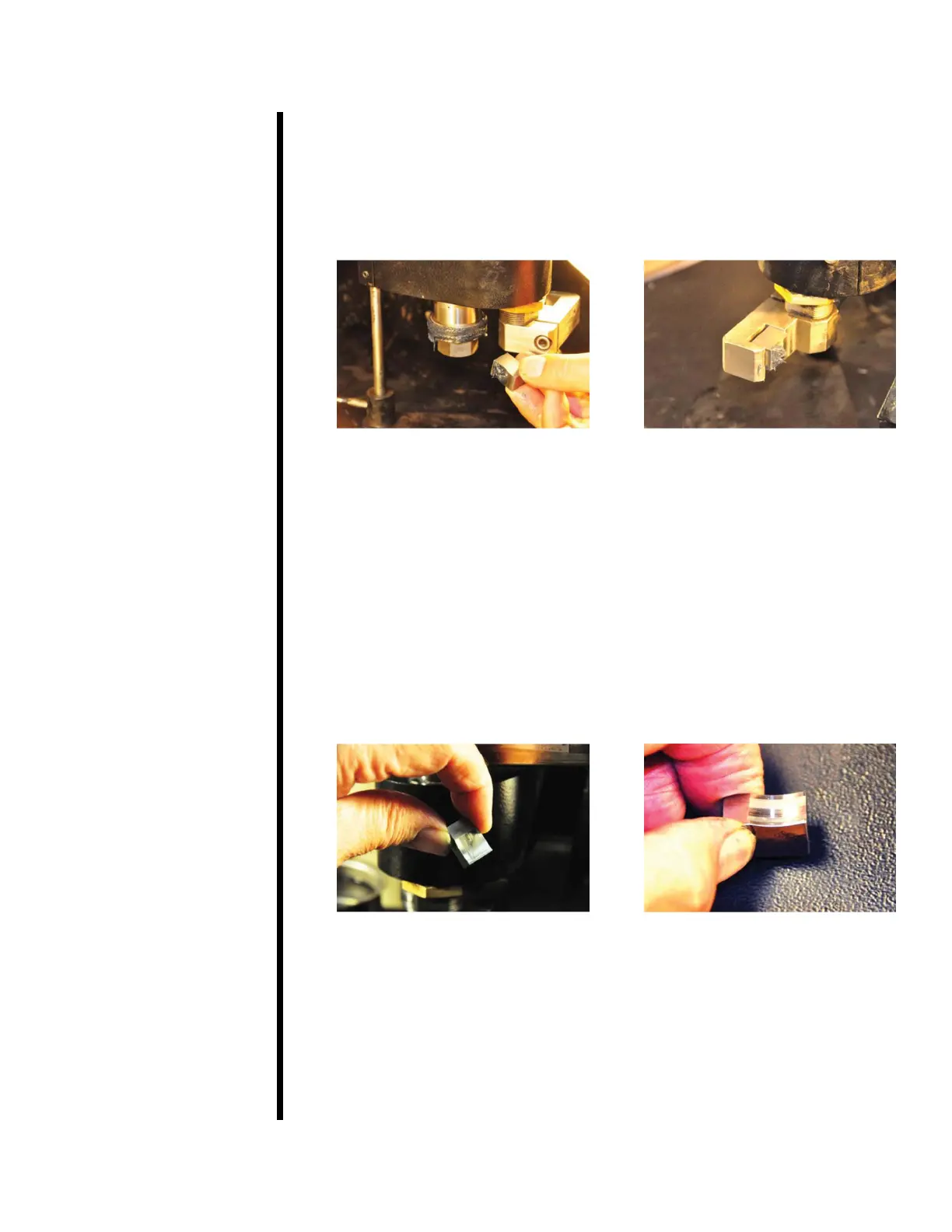

All new lubricity ring and block sets must be standardized (also called

“burning in” or “calibrating”) before running a test. This process ensures

complete contact between the ring and the concave surface of the block.

1. Cover the ring and contact area of the block with coarse grinding

compound.

2. Submerge the ring and block in fresh deionized water.

3. Press the exit button to zero the timer.

4. Set the motor speed to 90 rpm.

5. Apply 150 in-lb of torque.

6. Run for 2 hours, stopping every 30 minutes to redistribute the grinding

compound on the surface of the block.

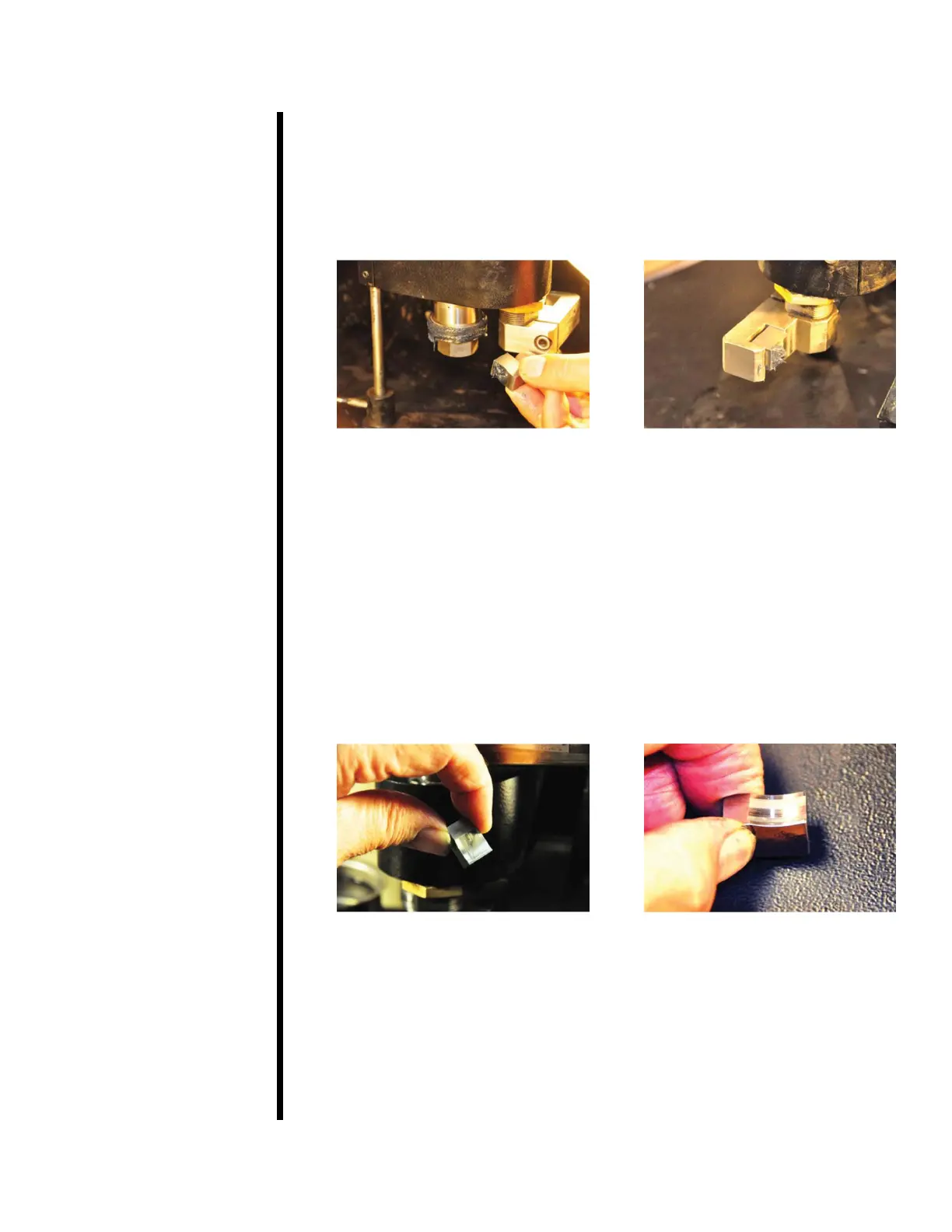

7. Stop the motor and observe the block. The block should show a shiny

wear pattern covering 30% to 50% of the surface. If it does not, return to

step 1.

8. Cover the ring and contact area of the block with ne grinding compound.

9. Submerge the ring and block in fresh deionized water.

10. Press the exit button to zero the timer.

11. Set the motor speed to 100 rpm.

Calibration

Standardizing the Ring

and Block

Loading...

Loading...