OFITE, 11302 Steeplecrest Dr., Houston, TX 77065 USA / Tel: 832-320-7300 / Fax: 713-880-9886 / www.ote.com 2

Introduction

When there is relative motion between two contacting bodies, frictional forces

that resist motion always come into play. Frictional resistance to rotation of

the drill string is called torque, and is especially enhanced when drilling a

deviated hole. Serious casing wear occurs in deep and ultra-deep wells. The

main inuential factor of casing wear is rotation of the drill pipe, horizontal

drilling, and tripping in and out of the hole. Many materials, such as Graphite,

Fine Mica, and Diesel or Crude Oil, have been used to improve lubricity.

Since evaluation of the various materials cannot realistically be done on the

drill string, a lubricity test was designed to simulate the speed of rotation of

the drill pipe and the pressure with which the pipe bears against the wall of

the bore hole. The OFITE combination EP (Extreme Pressure) and Lubricity

Tester is a high-quality instrument used to measure the lubricating quality

of drilling uids, provide data to evaluate the type and quantity of lubricating

additives that may be required, and predict wear rates of mechanical parts in

known uid systems.

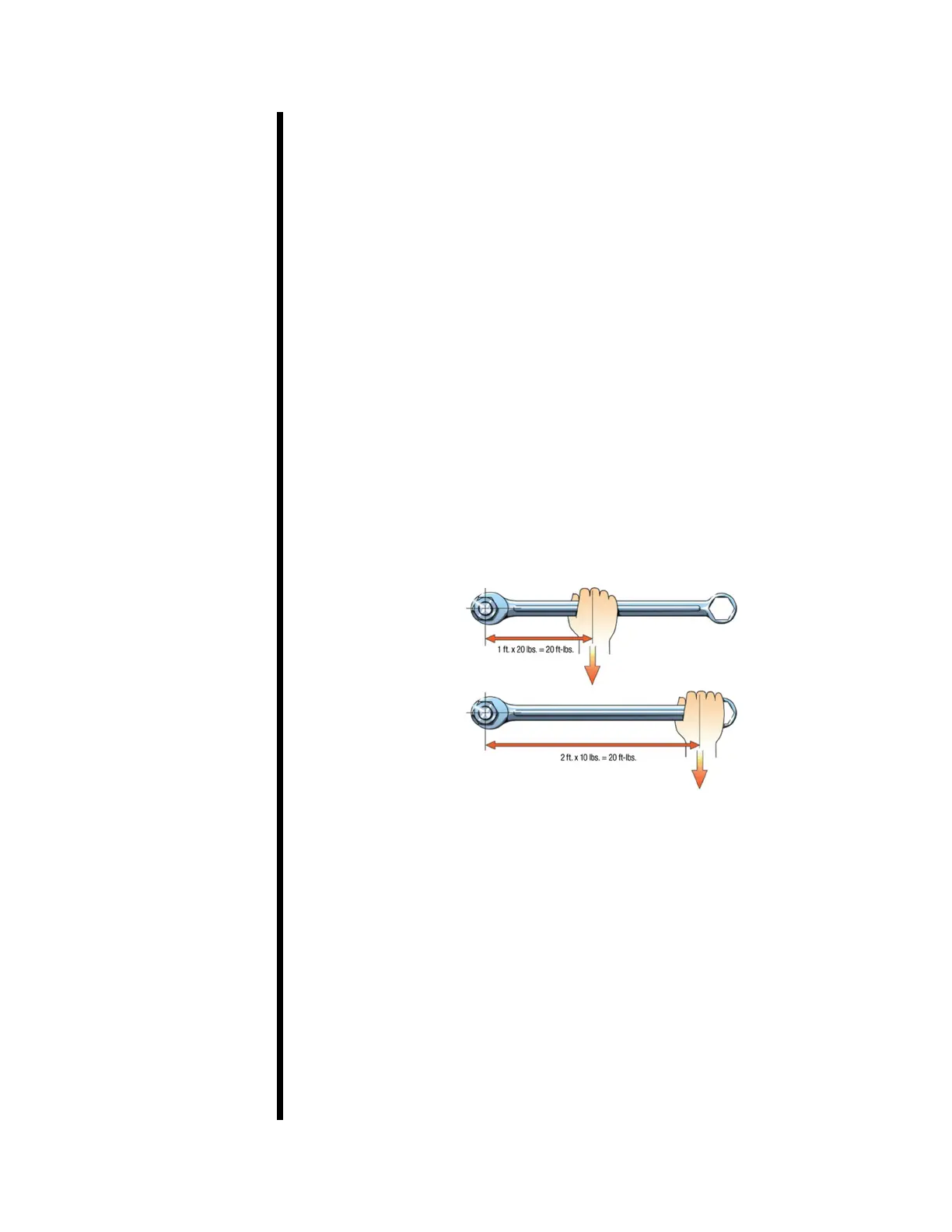

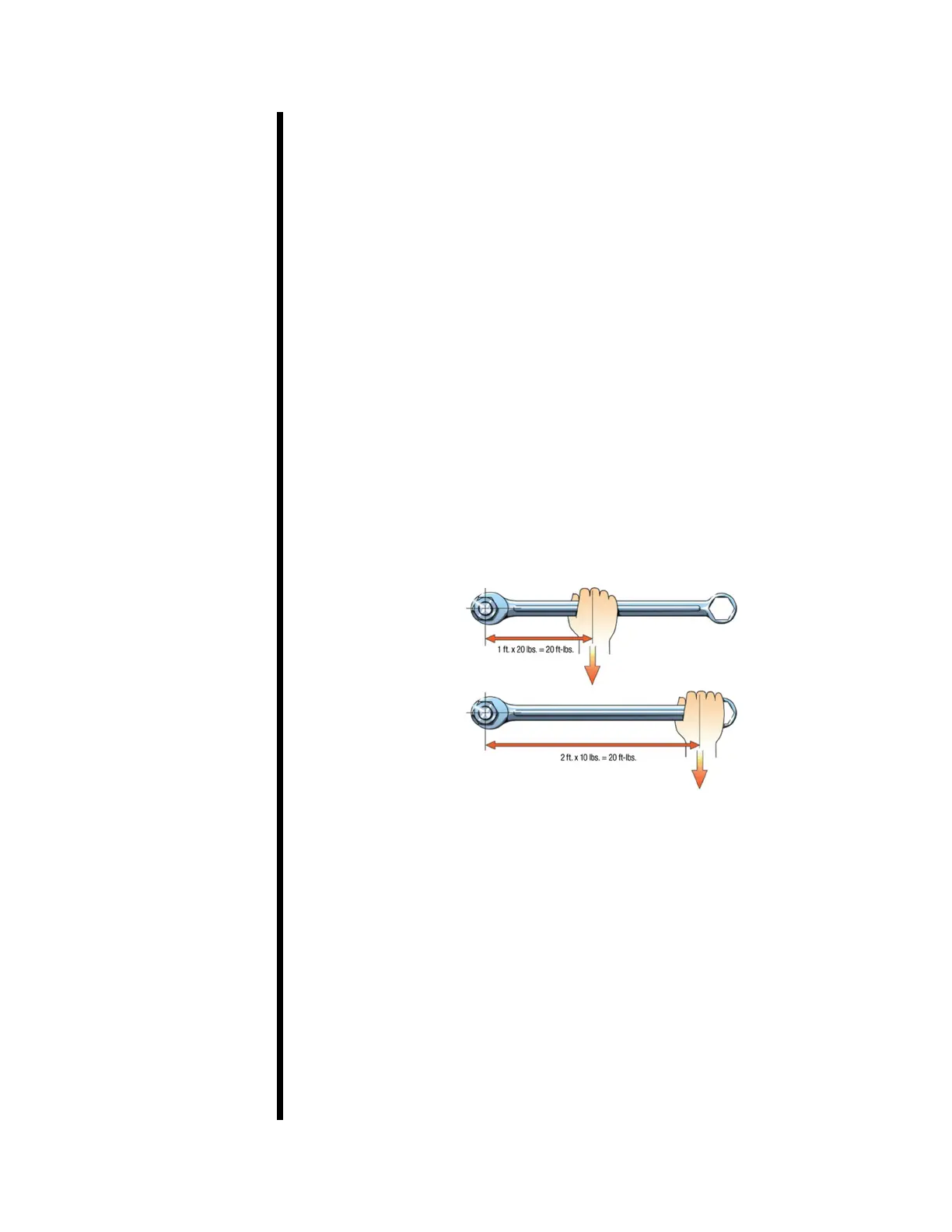

Inch – Pounds

Torque is dened as the measure of force applied to produce rotational

motion (usually measured in foot-pounds). Torque is determined by

multiplying the applied force by the distance from the pivot point to the point

where the force is applied. Inch-pounds × 0.0833 = Foot-pounds

Torque is measured in units of distance multiplied by force. A force of ten lb

acting through a distance of two feet produces exactly the same torque (20

ft-lb) as a force of twenty lb acting through a distance of one foot.

Loading...

Loading...