16

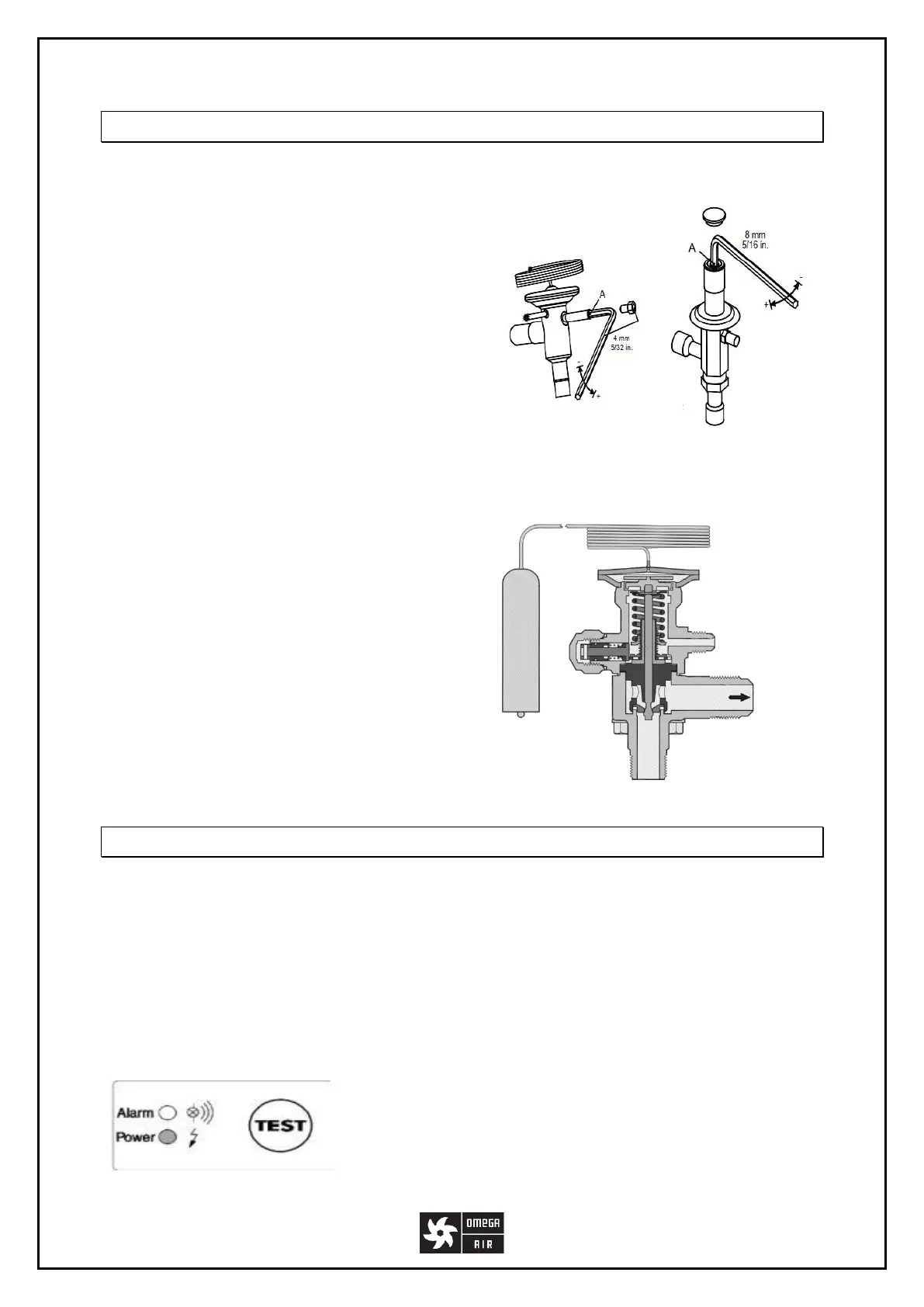

5.5 Expansion valves

This valve injects a portion of the hot gases (taken

from the compressor outlet) into the tube between

the evaporator and the suction side of the

compressor, thereby maintaining a constant

temperature / pressure of the evaporator at about +2

° C. This injection prevents the formation of ice in the

evaporator of the dryer under any load conditions.

SETTING

The hot gas bypass valve is factory set during the test

phase. As a rule, no additional settings are needed, but

if an intervention is required, an experienced cooler

technology engineer should do this.

The screw needs to be adjusted without the load on

the dryer. Rotate the screw until the following value is

reached:

Hot gas setting: R134.a pressure 2.0 barg (±0.1 bar)

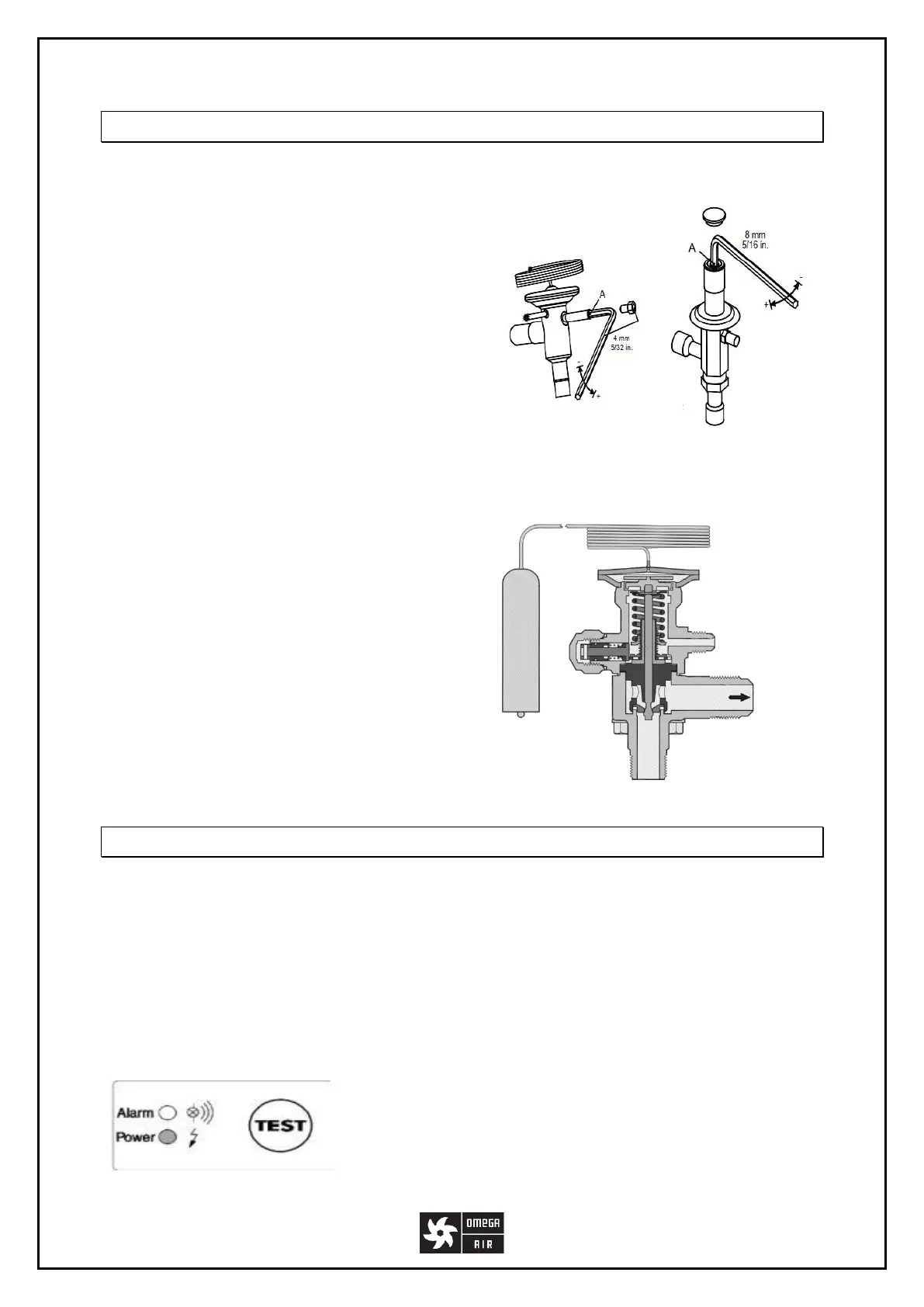

5.6. Electronic condensate drain

The separator consists of a condensate reservoir in which the capacitive sensor continuously checks

the level of the liquid. As soon as the tank is filled, the sensor sends the electronic board a signal and

the membrane solenoid valve opens and releases the condensate from the system. For a complete

drainage of the condensate, the valve opening time must be set precisely for each individual

condensate outlet. The impurity catcher is not built in. No settings required.

Electronic board

Loading...

Loading...