18

5.7 Safety functions

For protection against low-pressure, the low-pressure switch is added (RDP 750-1900). Other safety

functions are implemented in the controller.

5.7.1 Low-pressure switch

LPS: Low-pressure protection device on the suction side of the compressor trips, if the pressure drops

below the pre-set value. The values are automatically reset when the nominal conditions are restored.

Calibrated pressure: R 134.a Stop 0.7 barg - Restart 1.7 barg

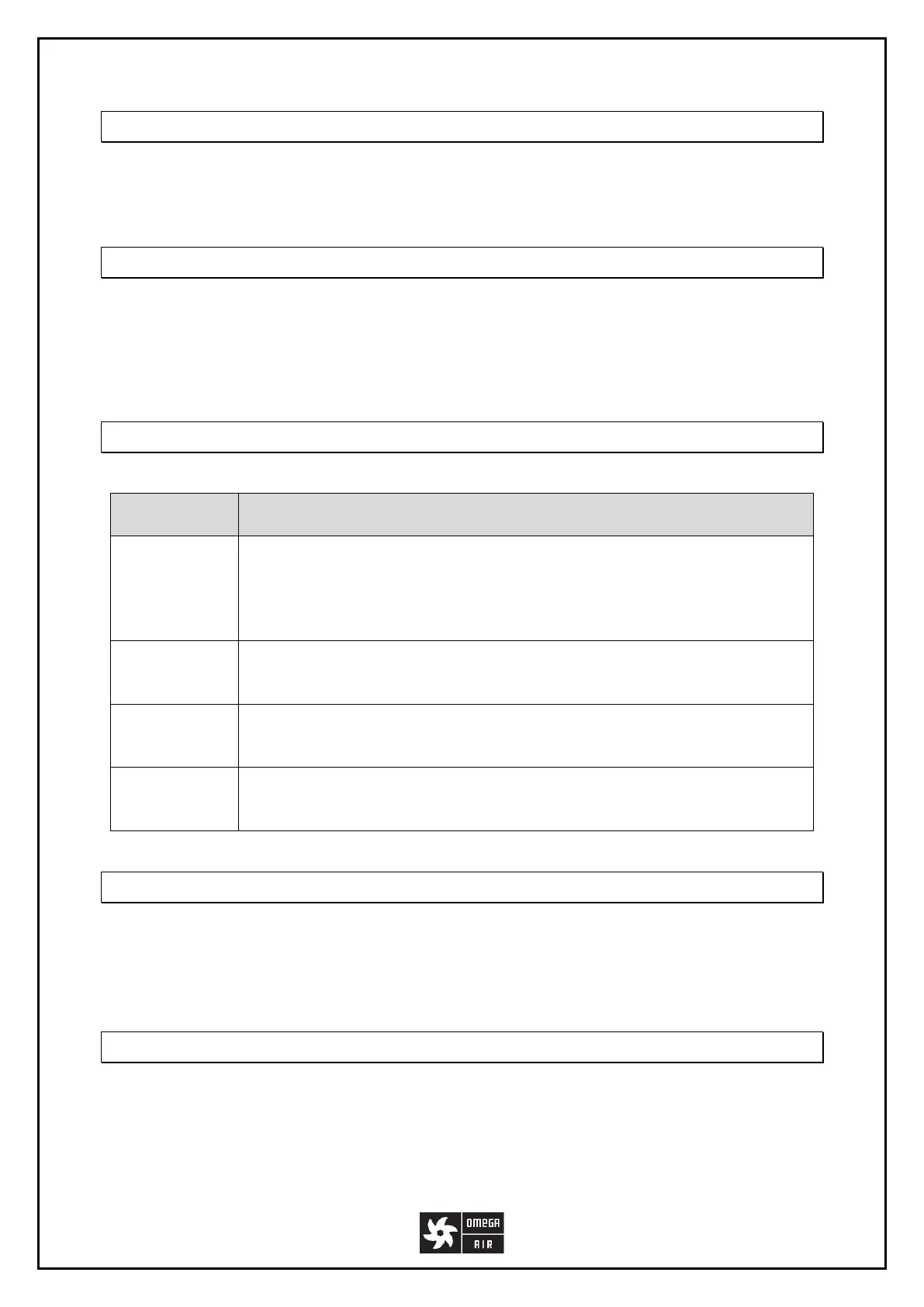

5.7.1 Safety functions of RDC 2

CAUSE - PROPOSED ACTIVITY

Temperature sensor failure - Ensure that the temperature sensor is properly

connected to the controller / replace the temperature switch

1 – Dew point sensor

2 – Compressor sensor

3 – Condensation sensor

High condensation temperature/pressure – Check that the temperature sensor

is correctly inserted into its position, check the cooling system sealing / charging

/ check the hot gas bypass valve

Low dew point temperature - Check that the temperature sensor is correctly

inserted into its position, check the cooling system sealing / charging / check the

hot gas bypass valve

High compressor outlet temperature – Check that the temperature sensor is

correctly inserted into its position, check the cooling system sealing / charging /

check the hot gas bypass valve

5.8 Filter / dehydrator

Moisture and impurities can be present in the refrigeration circuit. This can reduce the lubrication of

the compressor and block the expansion valve or capillary tube. The dryer filter / dehydrator is located

in front of the capillary tube to remove moisture and impurities from the circulation system.

5.9 Capillary tube

The capillary tube is located between the condenser and the evaporator and functions as a metering

device for reducing the pressure of the refrigerant. The pressure reduction is a design-based function.

The length and inner diameter of the capillary tube are precisely dimensioned, ensuring good

performance in all designed conditions.

Loading...

Loading...