Do you have a question about the Omega Calibre 3313 A and is the answer not in the manual?

Details the movement's height, diameter, power reserve, frequency, and lift angle.

Covers the automatic Co-Axial chronograph movement, its benefits, and critical handling points.

Lists components in order of assembly with part numbers and cross-references.

Specifies lubricants like Moebius HP-1300 and Moebius 9504 for specific parts.

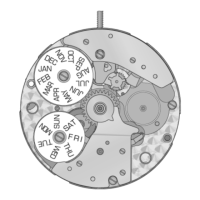

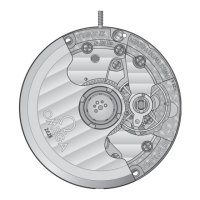

Provides visual references and part numbers for all components.

Lists parts with numbers, French, German, and English names for detailed reference.

Explains the chronograph wheel's function in both stopped and running states.

Illustrates the overall layout of the chronograph's wheel train and system components.

Details checking the eccentric screw for the minute counter jumper's alignment.

Guides the correct positioning of the hammer-lever banking bridge for proper function.

Verifies the correct positioning of the minute counter when the chronograph is reset.

Checks the chronograph finger's location and alignment in the reset position.

Ensures the safe and correct operation of the chronograph finger.

Verifies the accuracy and functionality of the minute jump mechanism.

Provides a visual schematic and describes the parts of the Co-Axial escapement.

Explains the technical principles and benefits of the Co-Axial escapement.

Details the interaction between the balance roller and the pallet during operation.

Describes how impulse is transferred to the balance roller via the pallet.

Details the precise method for lubricating the escape wheel and escapement.

Explains how to lubricate pinion teeth and the required quantity of lubricant.

Specifies lubrication for the escapement wheel, pinion, and co-axial wheel pivots.

Provides detailed instructions for assembling the balance bridge.

Provides detailed instructions for disassembling the balance bridge.

Explains how to adjust the balance using micro-regulating screws for accuracy.

Details the procedure and scale of the adjustment key for rate correction.

Specifies standard timing positions and acceptable rate variations for checks.

| Movement | Automatic |

|---|---|

| Caliber | 3313 |

| Power Reserve | 52 hours |

| Jewels | 37 |

| Chronograph | Yes |

| Diameter | 30 mm |

| Functions | Hours, minutes, small seconds, chronograph, date |

| Frequency | 28, 800 vibrations per hour (4 Hz) |

Loading...

Loading...