Take safety measures, such as installing a separate monitoring

system, to ensure safety even if the product fails. Product failure

may prevent comparative outputs from being generated, resulting

in serious accidents.

Observe the following precautions to ensure safety.

1. Maintain the power supply voltage within the range specified in

the specifications.

2. Maintain the load within the ratings specified in the specifications.

3. Check each terminal for correct number and polarity before con-

necting it. Incorrect or reverse connections may damage or burn

out internal components in the product.

4. Tighten the terminal screws securely. The recommended tighten-

ing torque is 0.43 to 0.58 N

⋅m. Loose screws may cause fire or

malfunction.

5. Do not connect anything to unused terminals.

6. Provide a switch or circuit breaker so that operators can easily

turn OFF the power supply when necessary. Also provide appro-

priate indications of such devices.

7. Do not attempt to disassemble, repair, or modify the product.

8. Do not use the product where flammable or combustible gases

are present.

Application

General Precautions

1. Do not use the product in the following locations:

• Locations subject to direct radiant heat from heating equip-

ment.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to direct sunlight.

• Locations subject to dust or corrosive gases (particularly sul-

furic gas or ammonia gas).

• Locations subject to severe changes in temperature.

• Locations subject to icing or condensation.

• Locations subject to shock or vibration.

2. Do not block heat dissipation around the product, i.e., provide suf-

ficient space for heat dissipation.

3. Ensure that the rated voltage is reached within two seconds after

the power is turned ON.

4. Conduct aging for 15 minutes min. after power is turned ON for

correct measurement.

5. Do not touch the slit sections or terminals while the power is

being supplied to prevent the product from being affected by static

electricity.

6. Do not lay heavy objects on the product during use or storage.

Doing so may deform or deteriorate the product.

7. Do not use paint thinner for cleaning. Use commercially available

alcohol.

Mounting

• Mount the product to a panel that is 1 to 8 mm thick.

• Install the product in a horizontal position.

• Use crimp terminals that match screw sizes.

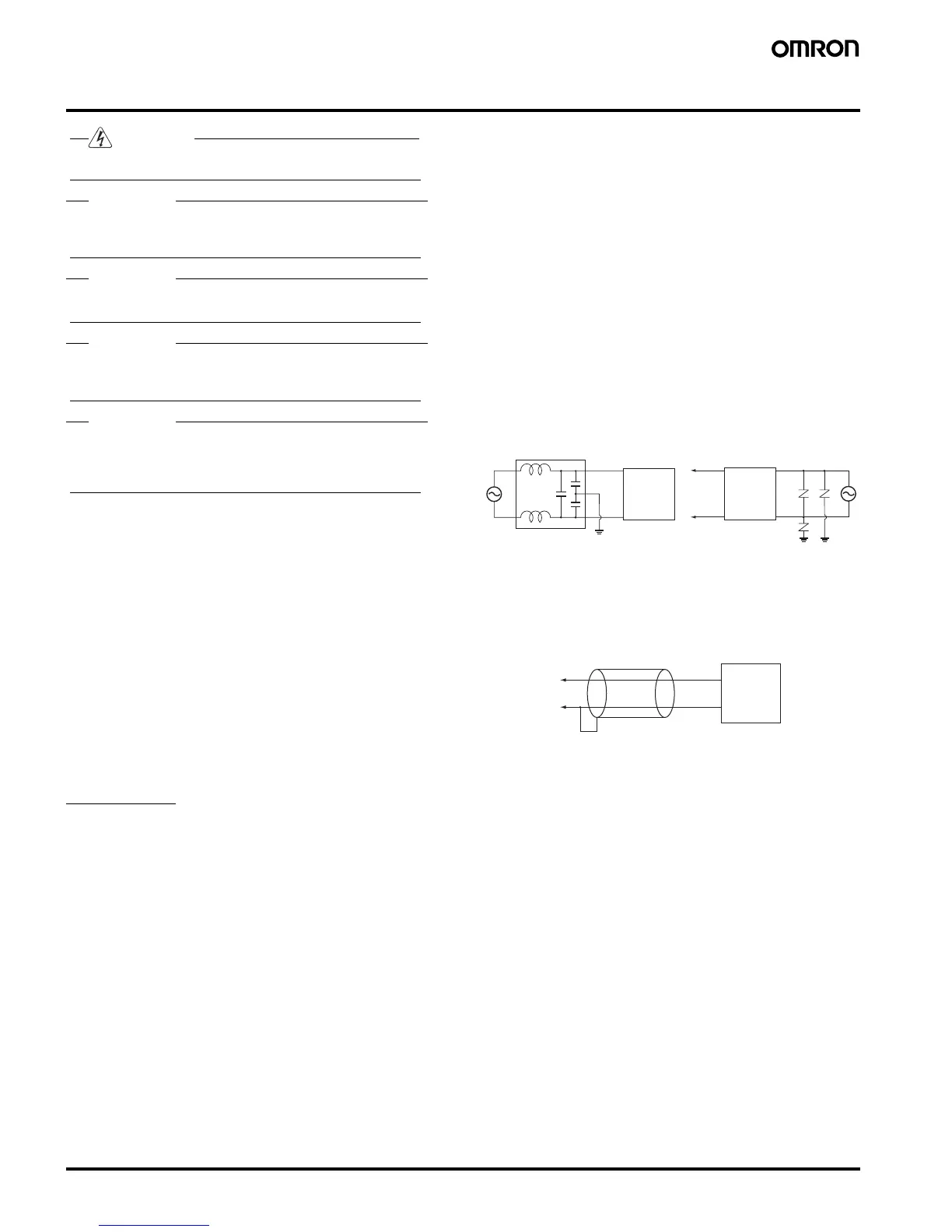

Noise Prevention

• Install the product as far as possible from devices that generate

strong, high-frequency fields (such as high-frequency welders or

sewing machines) or surges.

• Install surge absorbers or noise filters on nearby devices that gen-

erate noise (particularly, motors, transformers, solenoids, magnet

coils, and other devices that have a high inductance component).

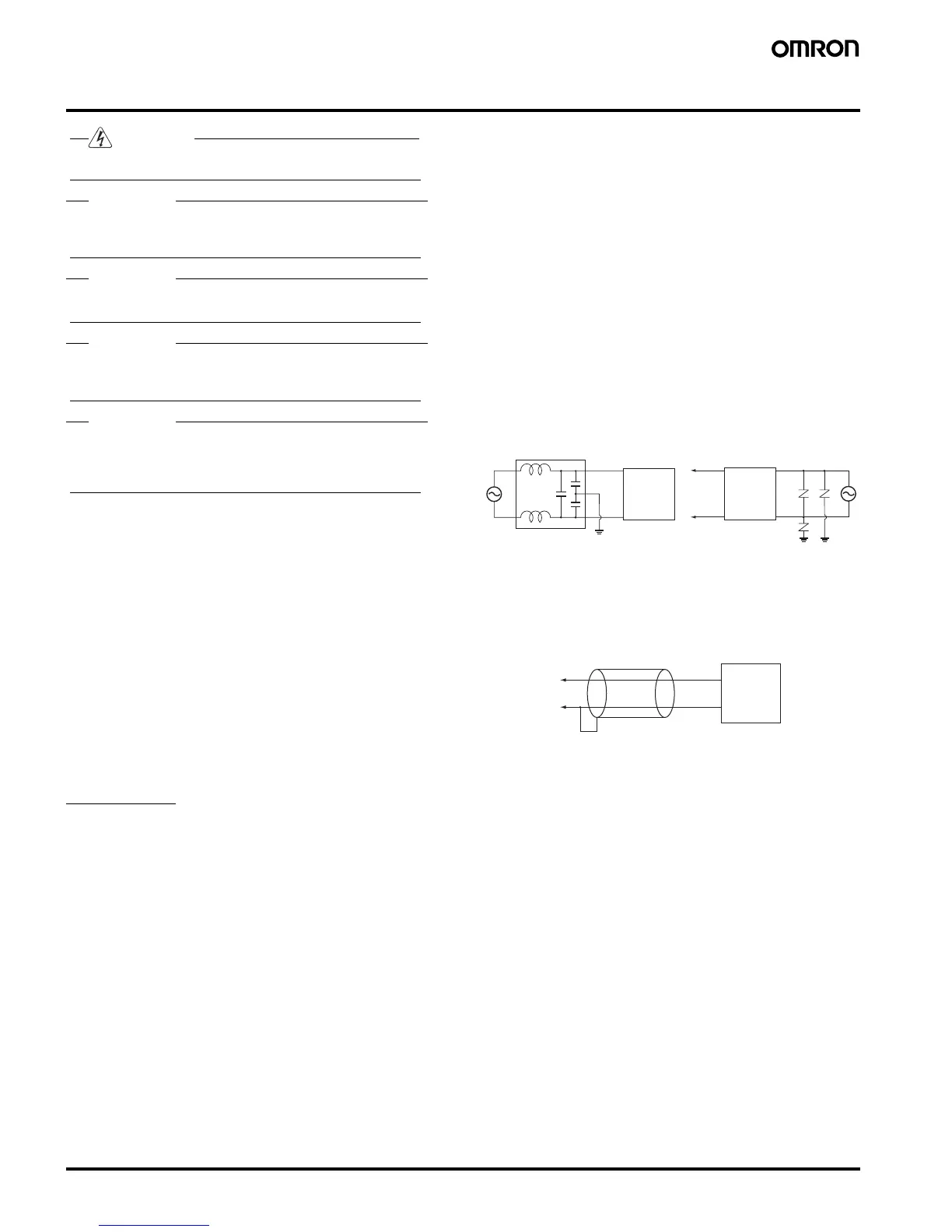

• To prevent inductive noise, separate the terminal block wiring for

the product from high-voltage or high-current power lines. Do not

route the wiring for the product in parallel with or tie it in a bundle

with power lines.

Take the following countermeasures against inductive noise in input

lines.

Analog Signal Inputs

• When using a noise filter for the power supply, check for the voltage

and current and install it as close as possible to the Process Meter.

• Do not install the product near radios, television sets, or wireless

devices. Doing so may cause reception interference.

Increasing Service Life

• Do not use the product in locations where the temperature or

humidity exceeds the ratings or where condensation may occur.

When installing the product in a panel, be sure that the temperature

around the product (not the temperature around the panel) does

not exceed the ratings. The product service life depends on the

ambient temperature. The higher the ambient temperature, the

shorter the service life. To extend the product service life, lower the

temperature inside the Process Meter.

• Use and store the product within the temperature and humidity

ranges given in the specifications. When gang-mounting Process

Meters or arranging them vertically, heat generated by the Process

Meters will cause the internal temperature to rise, reducing the ser-

vice life. In such cases, consider forced cooling methods, such as

using a fan to circulate air around the Process Meters. Do not, how-

ever, allow only the terminals to be cooled. Doing so will increase

measurement error.

• The life of the output relays is greatly affected by the switching

capacity and switching conditions. Use these relays within their

rated load and electrical life. The contacts may fuse or burn if they

are used past their electrical life.

+

−

Line filter

Power

supply

input

Process

Meter

Signal

input

Process

Meter

Power

supply

input

Surge absorber

+

−

Signal

input

2-conductor shielded cable

Process

Meter

Loading...

Loading...