8-42

8-5 Interface Monitor Setting Parameters

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

8

Parameter Details

Adjust the offset of the speed command input (REF: CN1 pin 18).

The offset amount is approx. the set value times 5 mV.

There are 2 ways to adjust the offset.

· Manual adjustment

· Automatic adjustment

The manual adjustment is as follows:

· To adjust the offset for individual drives, accurately input 0 V to the speed command input/

torque command input (REF/TREF1) (or connect to the signal ground), and then set this

parameter so that the motor does not rotate.

· If you use a position loop in the host device, set this parameter so that there are no

accumulated pulses at servo lock stop status.

The automatic adjustment is as follows:

This parameter will be automatically set when automatic offset adjustment is executed. Refer to

"Analog Input Automatic Offset Adjustment" (P.9-26) for the automatic offset adjustment method.

Set the first-order lag filter time constant in the speed command input (REF: CN1 pin 18).

Set the overflow level for speed command input (REF: CN1 pin 18) or torque command input

(TREF1: CN1 pin 14) using voltage after offset compensation.

Excessive analog input (Alarm No. 39) will be disabled if this parameter is set to 0.

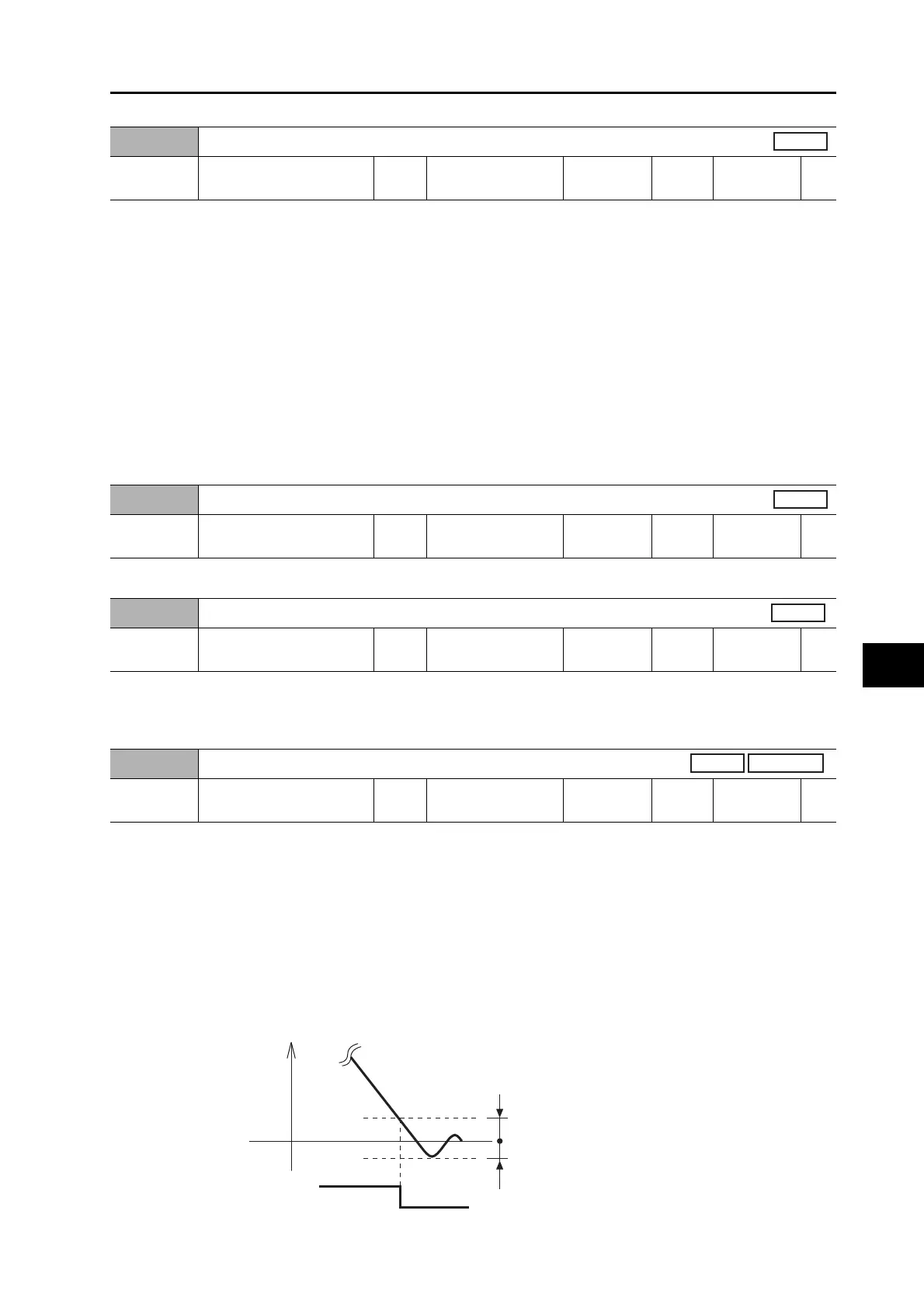

Use this parameter in combination with the Positioning Completion Condition Selection (Pn432) to set

the timing to output the positioning completion output (INP1). The positioning completion output (INP)

will output when the Servomotor (workpiece) movement stops and the number of the accumulated

pulses in the error counter is within the set value of this parameter, after command pulse input is

completed.

Unit for setting is command unit, but it can be changed to encoder unit with Position Setting Unit

Selection (Pn520). However, note that the unit for error counter overflow level will be changed as

well.

If this parameter is set to a very small value, the time required for the INP signal to be output will

increase and the chattering may occur during output. The setting of the positioning completion

range does not affect the precision of the final positioning.

Pn428

Analog Input 3 Offset

Setting

range

−342 to 342 Unit 5.86 mV

Default

setting

0

Power OFF

and ON

−

All

Pn429

Analog Input 3 Filter Time Constant

Setting

range

0 to 6,400 Unit 0.01 ms

Default

setting

0

Power OFF

and ON

−

Pn430

Excessive Analog Input 3

Setting

range

0 to 100 Unit 0.1 V

Default

setting

0

Power OFF

and ON

−

Pn431

Positioning Completion Range 1

Setting

range

0 to 262,144 Unit Command unit

Default

setting

10

Power OFF

and ON

−

Position

Fully-closed

INP

Accumulated

pulse

ON

Pn431

Pn431

Loading...

Loading...