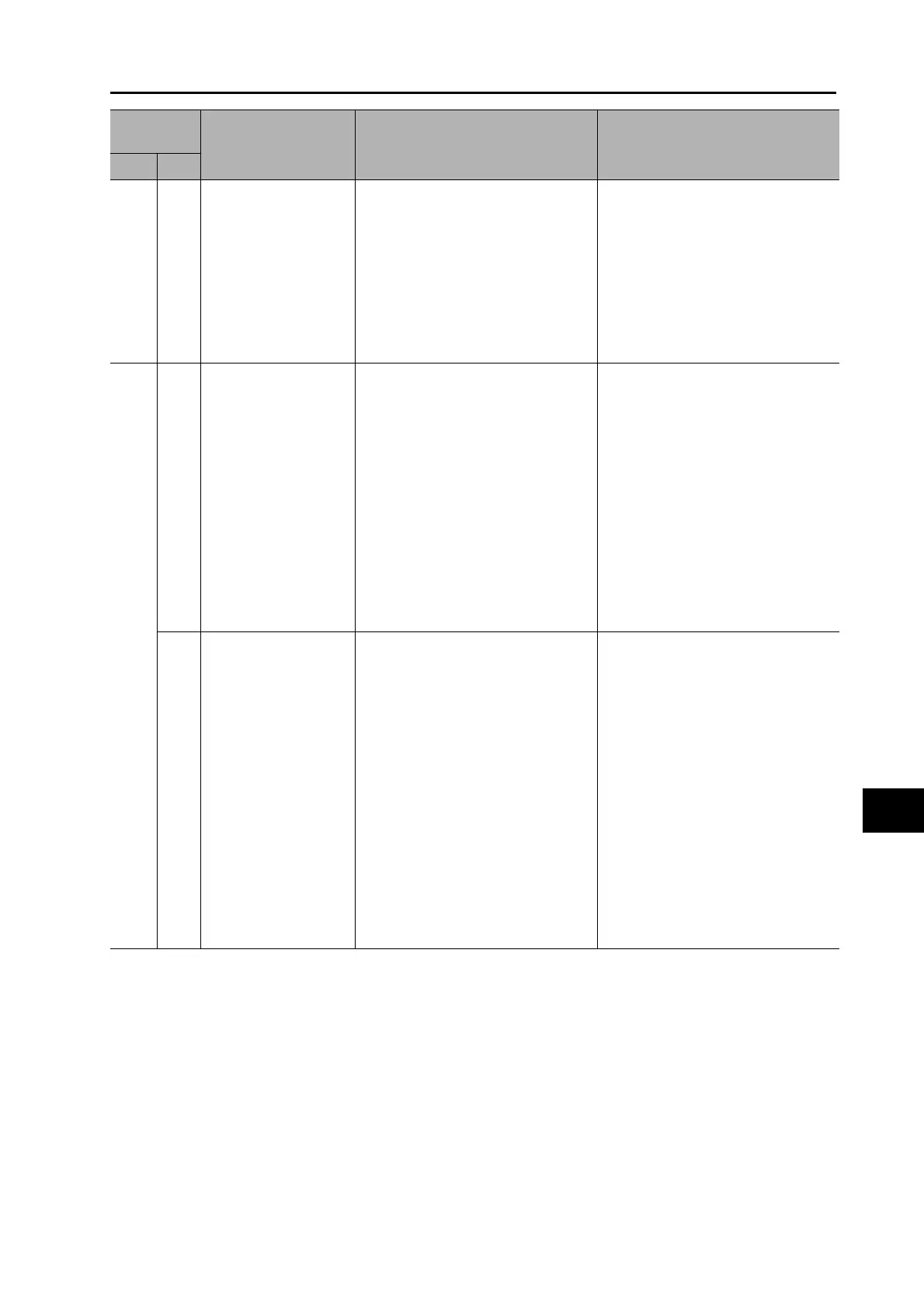

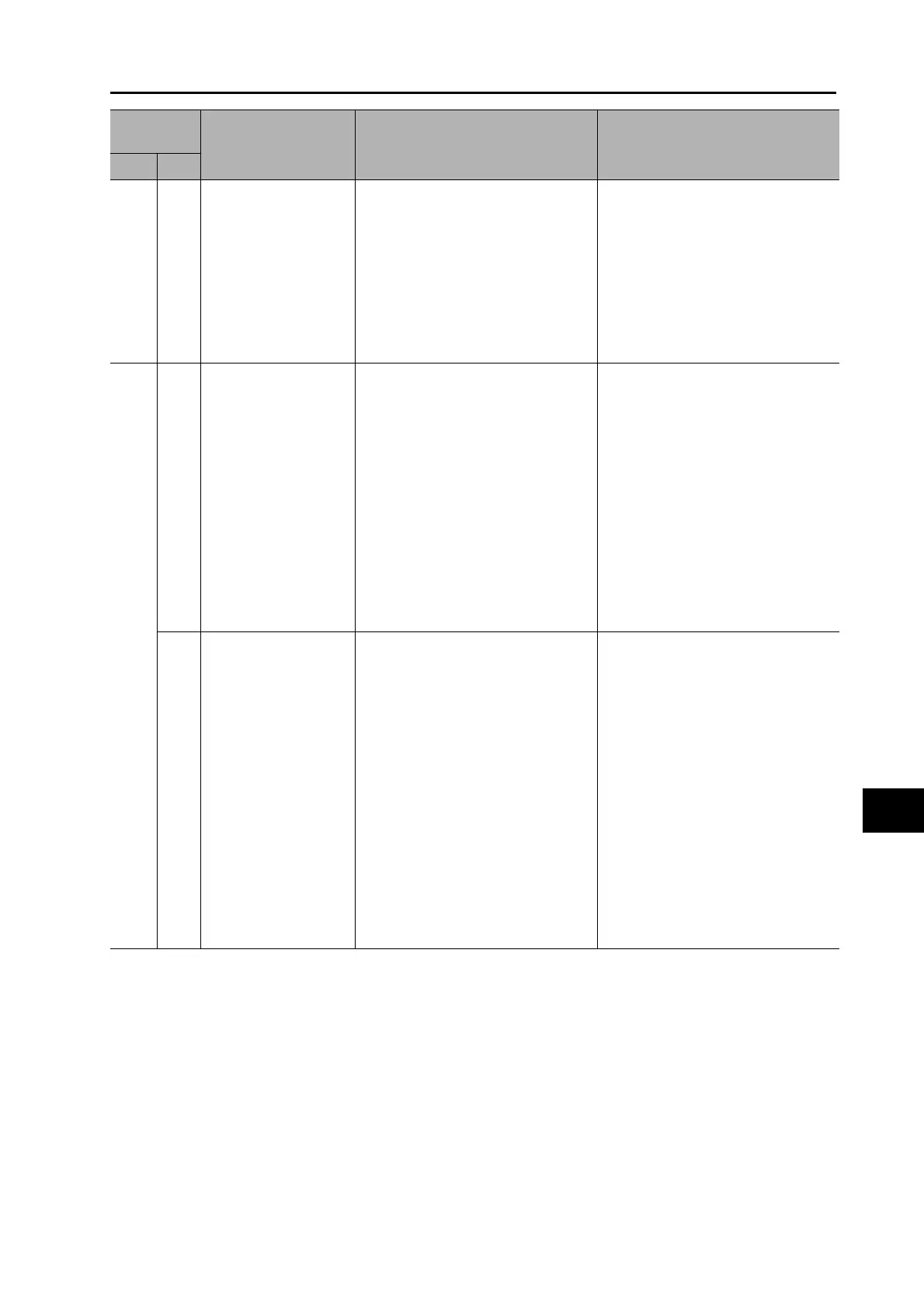

11-16

11-4 Troubleshooting

OMNUC G5-SERIES AC SERVOMOTOR AND SERVO DRIVE USER'S MANUAL

11

Troubleshooting and Maintenance

23 0

Encoder

communications data

error

No communications error occurred

with the data from the encoder, but

there is an error in the contents of the

data. There was a data error mainly

due to noise. The encode cable is

connected, but a communications

data error occurred.

· Provide the required encoder

power supply voltage of 5 VDC

±5% (4.75 to 5.25 V). Be careful

especially when the encode cable

is long.

· If the Servomotor cable and the

encoder cable are bundled

together, separate them.

· Connect the encoder cable

correctly.

24

0 Error counter overflow

Position error pulses exceeded the

setting of the Error Counter Overflow

Level (Pn014).

· Motor operation does not follow

the command.

· The value of the Error Counter

Overflow Level (Pn014) is small.

· Check to see if the Servomotor

rotates according to the position

command pulse. Check on the

torque monitor to see if the output

torque is saturated. Adjust the

gain. Set the No. 1 Torque Limit

(Pn013) or No. 2 Torque Limit

(Pn522) is set to the maximum

value. Connect the encoder cable

correctly. Lengthen the

acceleration and deceleration

times. Reduce the load and the

speed.

· Increase the set value for the Error

Counter Overflow Level (Pn014).

1 Excessive speed error

The difference between the internal

position command speed and the

motor speed (i.e., the speed error)

exceeded the Excessive Speed Error

Setting (Pn602).

Note: When the internal position

command speed is forced to 0

for an immediate stop due to a

command pulse prohibition

input (IPG) or forward/reverse

drive prohibition input, the

speed deviation immediately

increases. The speed

deviation also increases at the

start of the internal position

command speed. Therefore,

provide enough margin when

making the settings.

· Increase the set value of the

Excessive Speed Error Setting

(Pn602).

· Lengthen the acceleration time of

the internal position command

speed. Alternatively, improve the

tracking (following) performance

by adjusting the gain.

· Disable the Excessive Speed

Deviation Setting. (Pn602 = 0)

Alarm

number

Name Cause Measures

Main Sub

Loading...

Loading...