CP1H

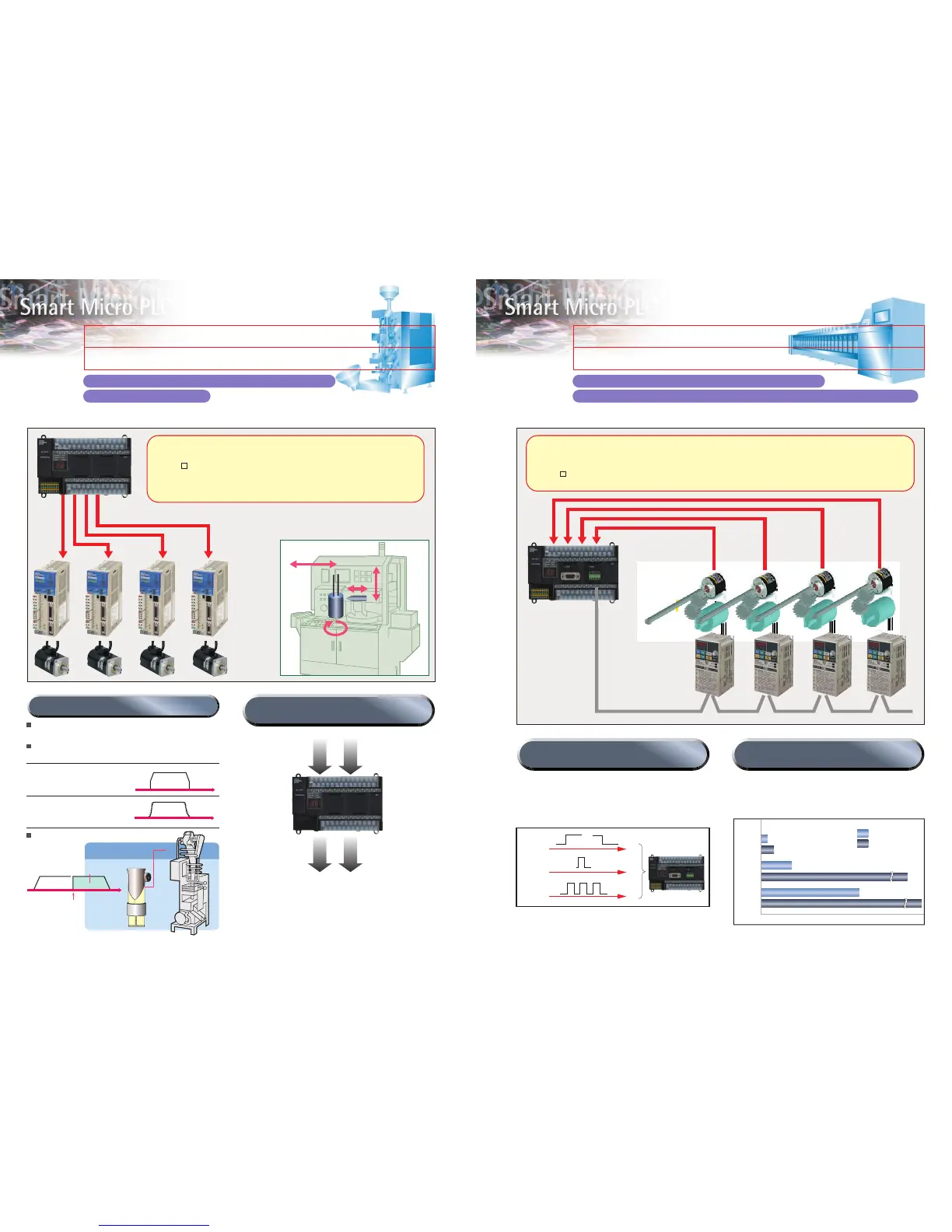

Example: Four-axis Control in Electronic

Component Manufacturing Equipment

Servo Drivers

Pulse outputs

Servomotors

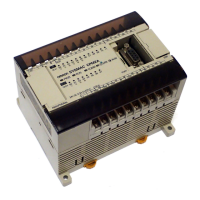

CP1H

Eight interrupt inputs are built in.

Quick-response inputs for pulse widths of 50 µs.

The interrupt inputs can also be used as single-

phase counters. (Response frequency: 5 kHz total

for 8 inputs)

Processing has been speeded up for not only

basic instructions but for special instructions as

well. Faster processing of approximately 400

instructions helps to speed up the entire system.

Inverters

High-speed counter

RS-485

LD instruction

CP1H

0.1 µs

0.3 µs

0.64 µs

7.8 µs

1.72 µs

16.3 µs

CPM2A

CPM1A

MOV instruction

Interrupt

inputs

8 normal inputs

Quick-response

inputs

Counter

inputs

Pulse Output Function for Up to Four Axes.

CP1H-Y CPU Units: Two axes at 1 MHz and two axes at 30 kHz

CP1H-X CPU Units: Two axes at 100 kHz and two axes at 30 kHz

The 8 normal inputs (6 for Y CPU Units) can be selected in the

PLC Setup as interrupt, quick-response, or counter inputs.

Four Axes are Standard.

Advanced Power for High-precision Positioning Control.

Electrolytic Capacitor Assembly by Electronic Component Manufacturing Equipment

Pulse Output Function

Along with greater precision and more flexibility in multi-product manufacturing,

high-speed multi-axis pulse output control responds to the increase in servo

applications.

Four-axis Counter Function (Single-phase or Differential Phases)

CP1H-Y CPU Units: Two axes, single-phase at 1 MHz or differential phases at 500 kHz plus two axes, single-phase

at 100 kHz or differential phases at 50 kHz

CP1H-X CPU Units: Four axes, single-phase at 100 kHz or differential phases at 50 kHz

Multi-axis counter inputs enable calculations for inverter positioning, spindle speed control in textile manufacturing, and much more.

Sheet Feeding for Vertical Pillow Packer

Capacitor removal

Processing

depth

Processing

positioning

Rotation

(final positioning)

A Full Range of Functions

A Full Range of Functions

Positioning with Trapezoidal Acceleration and

Deceleration (PLS2 Instruction)

Origin Search Function (ORG Instruction)

CP1H-Y

CPU Unit

Stop after output of

set number of pulses

PLS2 executed

Speed control

(ACC instruction)

Feed Control for

Packing Material

Target speed control

Specified number

of travel pulses

Acceleration

Start frequency

Deceleration

S-curve

acceleration

S-curve

deceleration

Origin searches are possible with a single ORG instruction.

1MHz High-speed Pulse Output

(CP1H-Y CPU Units : To be released soon.)

1MHz High-speed Pulse Output

(CP1H-Y CPU Units : To be released soon.)

Up to Eight Interrupt Inputs Can Be Used

Up to Eight Interrupt Inputs Can Be Used

Differential Phases for Four Axes Are Standard.

Easily Handles Multi-axis Control with a Single Unit.

Main-axis Control for Equipment Such as Textile Machinery or Spinning Machinery

High-speed Counter Function

Positioning Conveyance for Equipment Such as Building Material Manufacturing Machinery and Stone-cutting Machinery

Rotary

encoders

General-

purpose

motors

Interrupt Feeding (ACC and PLS2

Instructions)

Easily achieved with special

positioning instruction (PLS2).

S-curve acceleration/ deceleration

can be used to reduce vibration in

high-speed positioning.

Two 1-MHz

high-speed counter

line-driver inputs

(special pulse input

terminals)

Two 1-MHz

high-speed counter

line-driver outputs

(special pulse output

terminals)

Two high-speed

counter normal inputs

(100 kHz)

Two 30-kHz

normal pulse outputs

CP1H-Y CPU Units offer built-in 1-MHz line-driver I/O.

• Line-driver outputs: Two each for CW and CCW.

• Line-driver inputs: Two each for phases A, B, and Z.

CP1H-Y CPU Units also have 20 normal I/O points (12 inputs

and 8 outputs), and can provide 100-kHz high-speed counter

inputs for two axes and 30-kHz pulse outputs for two axes.

Compared with the CPM2A, Basic Instructions Are

Processed at Least Six Times Faster and MOV Instructions

are Processed 26 Times Faster.

Compared with the CPM2A, Basic Instructions Are

Processed at Least Six Times Faster and MOV Instructions

are Processed 26 Times Faster.

Loading...

Loading...