INSPECTION

AND

CLEANING

When inspecting the rotating rectifier assembly,

make sure diodes are free of dust, dirt and grease.

Excessive foreign matter on these diodes and heat

sinks will cause the diodes to overheat and will result

in their failure. Blow out the assembly periodically,

with filtered, low pressure air. Also check to see that

diodes and leadwires are properly torqued. The

diodes should be torqued to 30 in. Ib. (3.4 N*m) or

finger tight plus a-quarter

turn.

Blow dust out of

control panel.

BATTERIES

Check the condition of the starting batteries at least

every two weeks. See that connections are clean and

tight. A light coating of non-conductive grease will

retard corrosion at terminals. Keep the electrolyte at

the proper level above the plates by adding distilled

water. Check specif ic gravity, recharge if below

1.280.

CONNECTIONS

(Fuel,

Exhaust,

etc.)

Operator should periodically make a complete visual

inspection of the set while running at rated

load.

Some of the things to check for are as follows:

1.

Check all fuel and oil lines for possible leakage.

2.

Inspect exhaust lines and mufflers for possible

leakage and cracks.

3. Periodicallyordaily, drain moisture from conden-

sation traps.

4.

Inspect water lines and connections for leaks and

security.

5. Inspect electrical wires and connections for

security and fray damage.

If generator requires major repair or servicing, contact an authoriz-

ed Onan dealer or distributor.

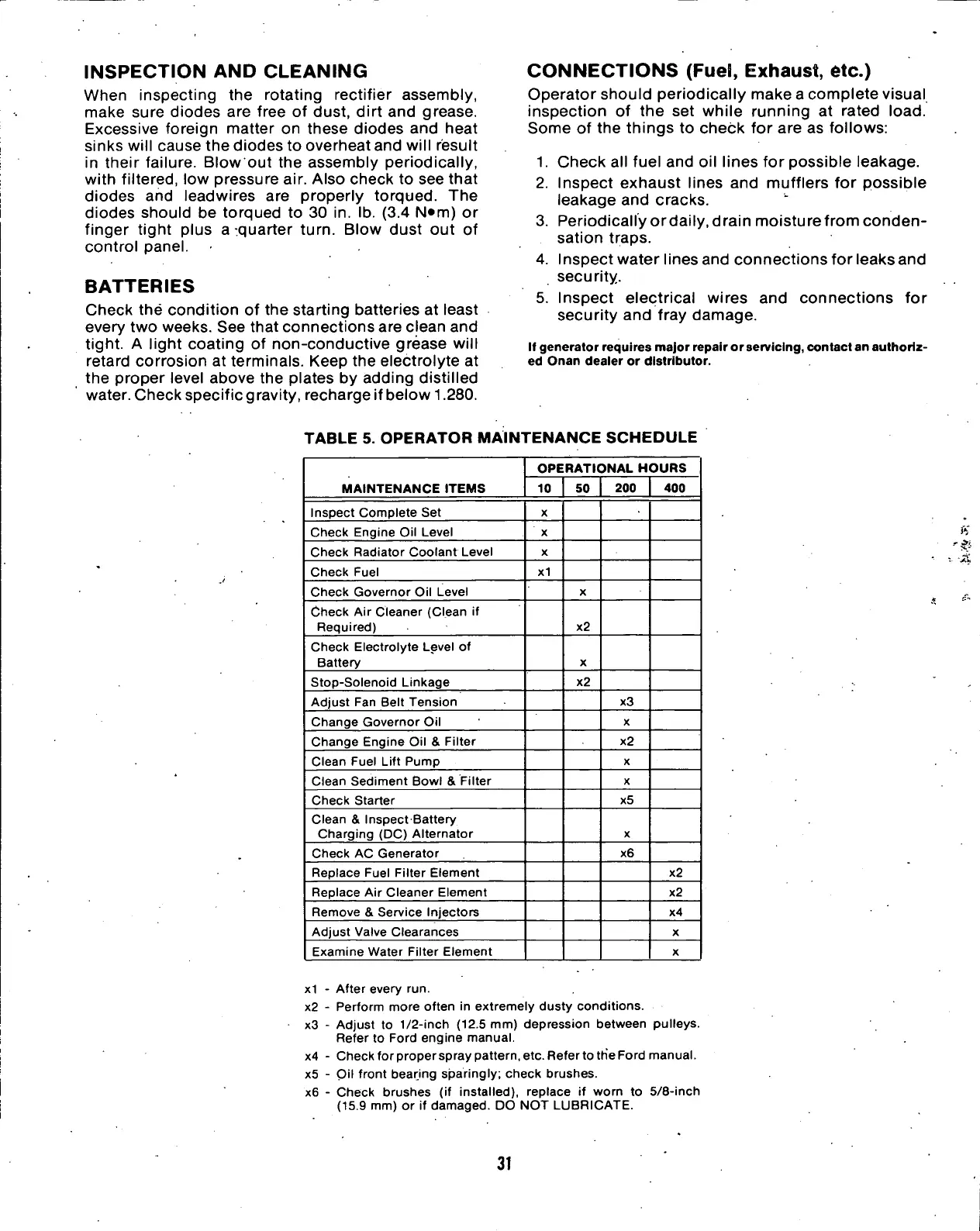

TABLE

5.

OPERATOR

MAINTENANCE

SCHEDULE

MAINTENANCE ITEMS

OPERATIONAL HOURS

MAINTENANCE ITEMS 10 50

200 400

Inspect Complete Set

X

Check Engine Oil Level

X

Check Radiator Coolant Level

X

Check Fuel

xl

Check Governor Oil Level

X

Check Air Cleaner (Clean if

Required)

x2

Check Electrolyte Level of

Battery

x

Stop-Solenoid Linkage

x2

Adjust Fan Belt Tension x3

Change Governor Oil

X

Change Engine Oil & Filter

x2

Clean Fuel Lift Pump

X

Clean Sediment Bowl & Filter

X

Check Starter

x5

Clean & Inspect Battery

Charging (DC) Alternator

X

Check AC Generator

x6

Replace Fuel Filter Element x2

Replace Air Cleaner Element x2

Remove & Service Injectors

x4

Adjust Valve Clearances

X

Examine Water Filter Element X

ft

•4

xl - After every run.

x2 - Perform more often in extremely dusty conditions.

x3 - Adjust to

1/2-inch

(12.5 mm) depression between pulleys.

Refer to Ford engine manual.

x4 - Check for proper spray pattern, etc. Refer to the Ford manual.

x5 - Oil front bearing sparingly; check brushes.

x6 - Check brushes (if installed), replace if worn to 5/8-inch

(15.9 mm) or if damaged. DO NOT LUBRICATE.

31

Loading...

Loading...