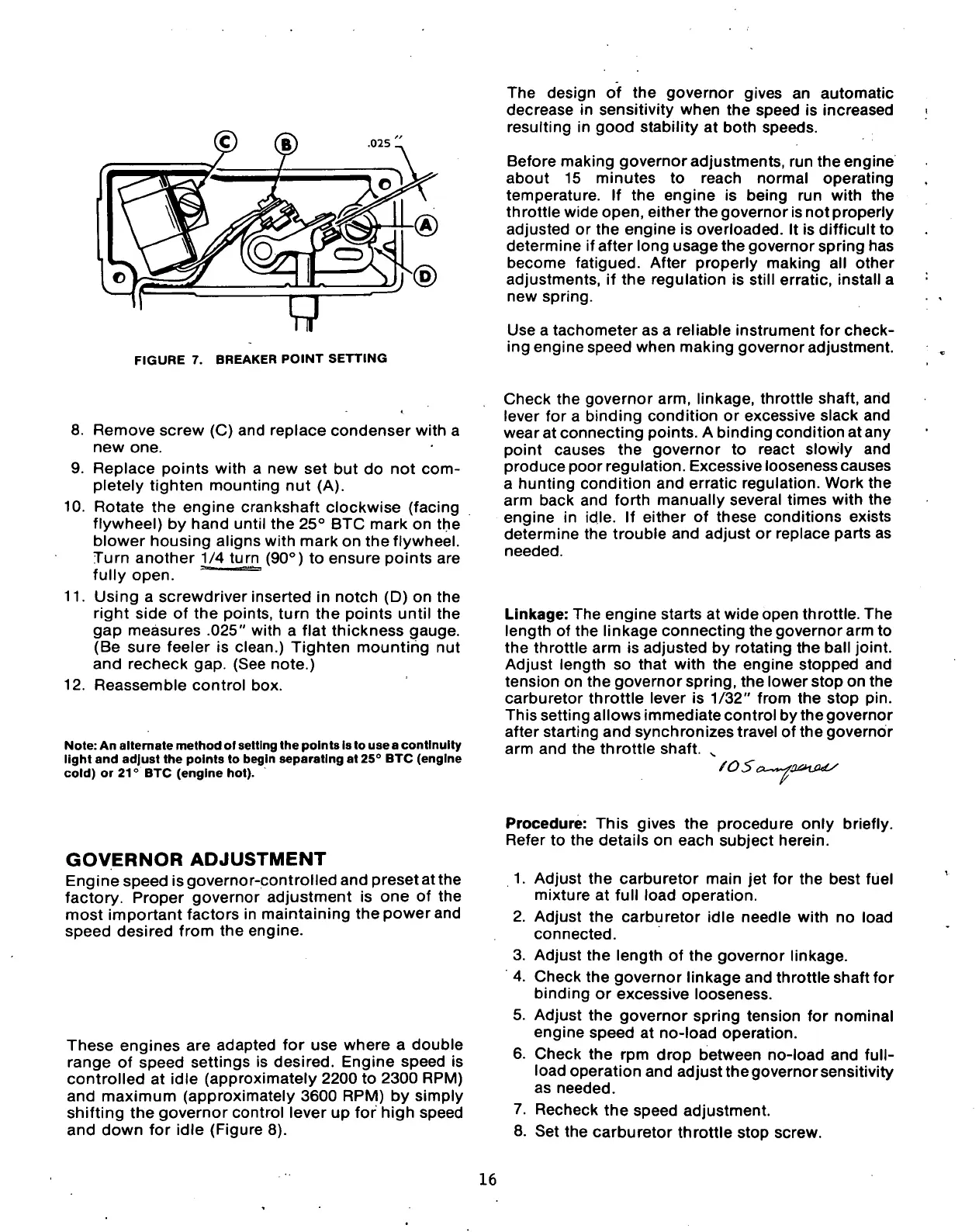

FIGURE 7. BREAKER POINT SETTING

The design of the governor gives an automatic

decrease in sensitivity when the speed is increased

resulting in good stability at both speeds.

Before making governor adjustments, run theengine

about 15 minutes to reach normal operating

temperature. If the engine is being run with the

th rottle wide open, either the governor is not properly

adjusted or the engine is overloaded. It is difficult to

determine if after long usage the governor spring has

become fatigued. After properly making all other

adjustments, if the regulation is still erratic, install a

new spring.

Use a tachometer as a reliable instrument for check-

ing engine speed when making governor adjustment.

8. Remove screw (C) and replace condenser with a

new one.

9. Replace points with a new set but do not com-

pletely tighten mounting nut (A).

10.

Rotate the engine crankshaft clockwise (facing

flywheel) by hand until the 25° BTC mark on the

blower housing aligns with mark on the flywheel.

Turn another 1/4 turn (90°) to ensure points are

fully open. "

11.

Using a screwdriver inserted in notch (D) on the

right side of the points, turn the points until the

gap measures .025" with a flat thickness gauge.

(Be sure feeler is clean.) Tighten mounting nut

and recheck gap. (See note.)

12.

Reassemble control box.

Note:

An altemate method of setting the points is to use a continuity

light and adjust the points to begin separating at 25° BTC (engine

cold) or 21° BTC (engine hot).

Check the governor arm, linkage, throttle shaft, and

lever for a binding condition or excessive slack and

wear at connecting points. A binding condition at any

point causes the governor to react slowly and

produce poor regulation. Excessive looseness causes

a hunting condition and erratic regulation. Work the

arm back and forth manually several times with the

engine in idle. If either of these conditions exists

determine the trouble and adjust or replace parts as

needed.

Linkage: The engine starts at wide open throttle. The

length of the linkage connecting the governor arm to

the throttle arm is adjusted by rotating the ball joint.

Adjust length so that with the engine stopped and

tension on the governor spring, the lower stop on the

carburetor throttle lever is 1/32" from the stop pin.

This setting allows immediate control by thegovernor

after starting and synchronizes travel of the governor

arm and the throttle shaft.

GOVERNOR

ADJUSTMENT

Engine speed is governor-controlled and preset at the

factory. Proper governor adjustment is one of the

most important factors in maintaining the power and

speed desired from the engine.

These engines are adapted for use where a double

range of speed settings is desired. Engine speed is

controlled at idle (approximately 2200 to 2300 RPM)

and maximum (approximately 3600 RPM) by simply

shifting the governor control lever up for high speed

and down for idle (Figure 8).

Procedure: This gives the procedure only briefly.

Refer to the details on each subject herein.

1.

Adjust the carburetor main jet for the best fuel

mixture at full load operation.

2.

Adjust the carburetor idle needle with no load

connected.

3. Adjust the length of the governor linkage.

4.

Check the governor linkage and throttle shaft for

binding or excessive looseness.

5. Adjust the governor spring tension for nominal

engine speed at no-load operation.

6. Check the rpm drop between no-load and

full-

load operation and adjust the governor sensitivity

as needed.

7. Recheck the speed adjustment.

8. Set the carburetor throttle stop screw.

16

Loading...

Loading...