OPEN

CIRCUIT

TEST

The most likely place to check for an open circuit is at

the commutator riser bars. Inspect for loose connec-

tions on the points where the conductors are joined to

the commutator bars.

STARTER ASSEMBLY

Reassembly is the reverse of disassembly. When

reassembling, wipe off any dirty parts with a clean

cloth or blow clean using filtered compressed air.

Bearings must not be immersed in cleaning

fluid.

These parts

should be cleaned with a brush dipped in clean engine oil.

Apply SAE 10W-30 oil on the armature shaft, spline

and bearings.

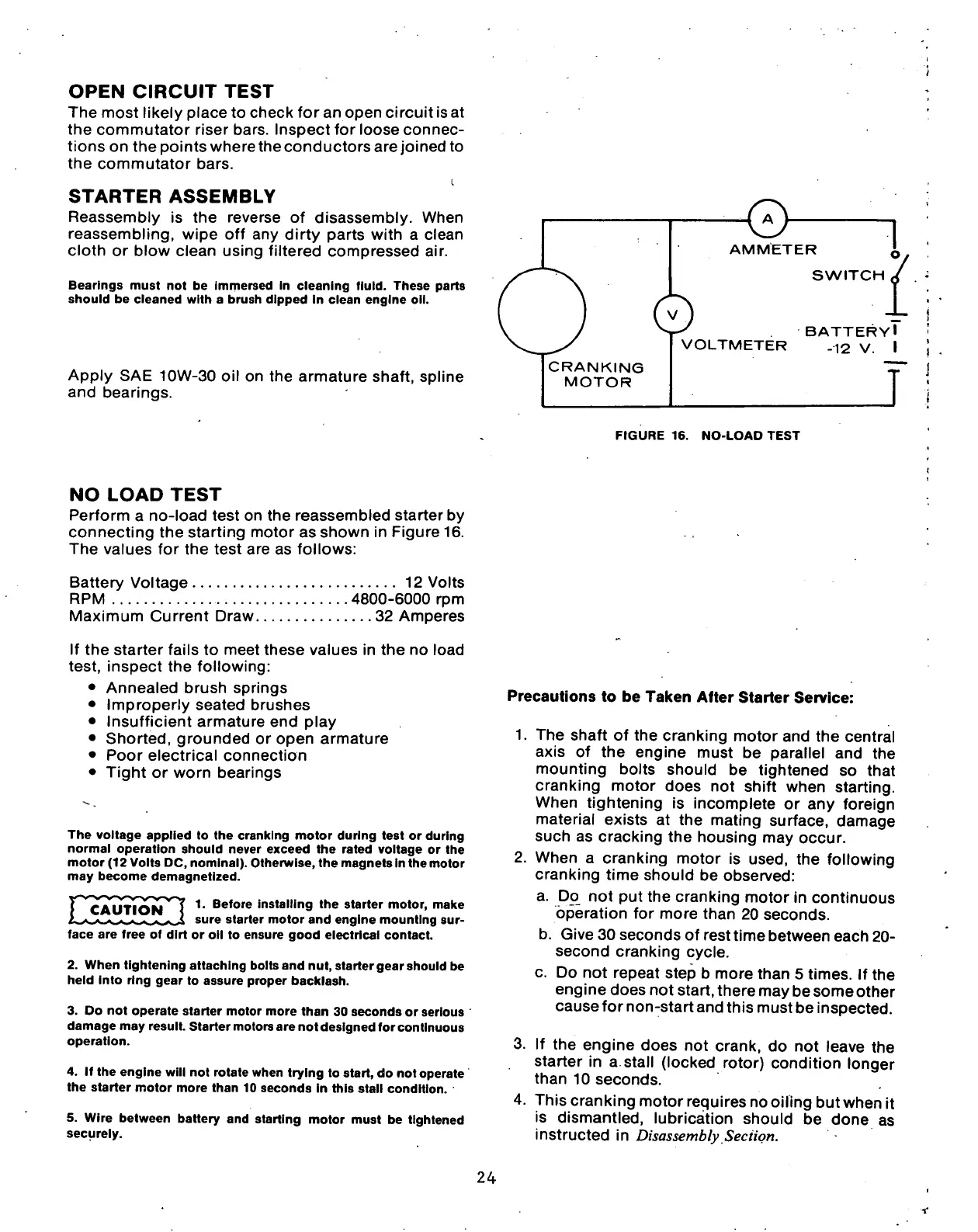

AMMETER

SWITCH

0

7.;

CRANKING

MOTOR

BATTERY!

VOLTMETER

-12 V. I

NO

LOAD

TEST

Perform a no-load test on the reassembled starter by

connecting the starting motor as shown in Figure 16.

The values for the test are as follows:

FIGURE 16. NO-LOAD TEST

Battery Voltage 12 Volts

RPM 4800-6000 rpm

Maximum Current Draw 32 Amperes

If the starter fails to meet these values in the no load

test, inspect the following:

• Annealed brush springs

• Improperly seated brushes

• Insufficient armature end play

• Shorted, grounded or open armature

• Poor electrical connection

• Tight or worn bearings

The voltage applied to the cranking motor during test or during

normal operation should never exceed the rated voltage or the

motor (12 Volts DC, nominal). Otherwise, the magnets

in

the motor

may become demagnetized.

CAUTION

>

T

1

'

Be,ore

'

ns,all

'

n

g the starter motor, make

sure starter motor and engine mounting sur-

face are free of dirt or oil to ensure good electrical contact.

2.

When tightening attaching bolts and nut, starter gear should be

held into ring gear to assure proper backlash.

3. Do not operate starter motor more than 30 seconds or serious

damage may result. Starter motors are not designed for continuous

operation.

4.

If the engine will not rotate when trying to start, do not operate

the starter motor more than 10 seconds in this stall condition.

5. Wire between battery and starting motor must be tightened

securely.

Precautions to be Taken After Starter Service:

1.

The shaft of the cranking motor and the central

axis of the engine must be parallel and the

mounting bolts should be tightened so that

cranking motor does not shift when starting.

When tightening is incomplete or any foreign

material exists at the mating surface, damage

such as cracking the housing may occur.

2.

When a cranking motor is used, the following

cranking time should be observed:

a. Do not put the cranking motor in continuous

operation for more than 20 seconds.

b. Give 30 seconds of rest time between each 20-

second cranking cycle.

c. Do not repeat step b more than 5 times. If the

engine does not start, there may be some other

cause for non-start and this must be inspected.

3. If the engine does not crank, do not leave the

starter in a stall (locked rotor) condition longer

than 10 seconds.

4. This cranking motor requires no oiling but when it

is dismantled, lubrication should be done as

instructed in

Disassembly

Section.

24

Loading...

Loading...