ENGINE

DISASSEMBLY

VALVE

SYSTEM

Properly seated valves are essential to good engine

performance. The aluminum cylinder heads are

removable for valve servicing. Do not use a pry to

loosen the cylinder

head;

rap sharply on the edge with

a soft faced hammer, taking care not to break any

cooling fins. A conventional type valve spring lifter

may be used when removing the valve spring locks,

which are of the split type. Clean all carbon deposits

from the cylinder heads, piston tops, valves, guides,

etc. If a valve face is burned or warped, or the stem

worn,

install a new valve. Refer to Figure 17.

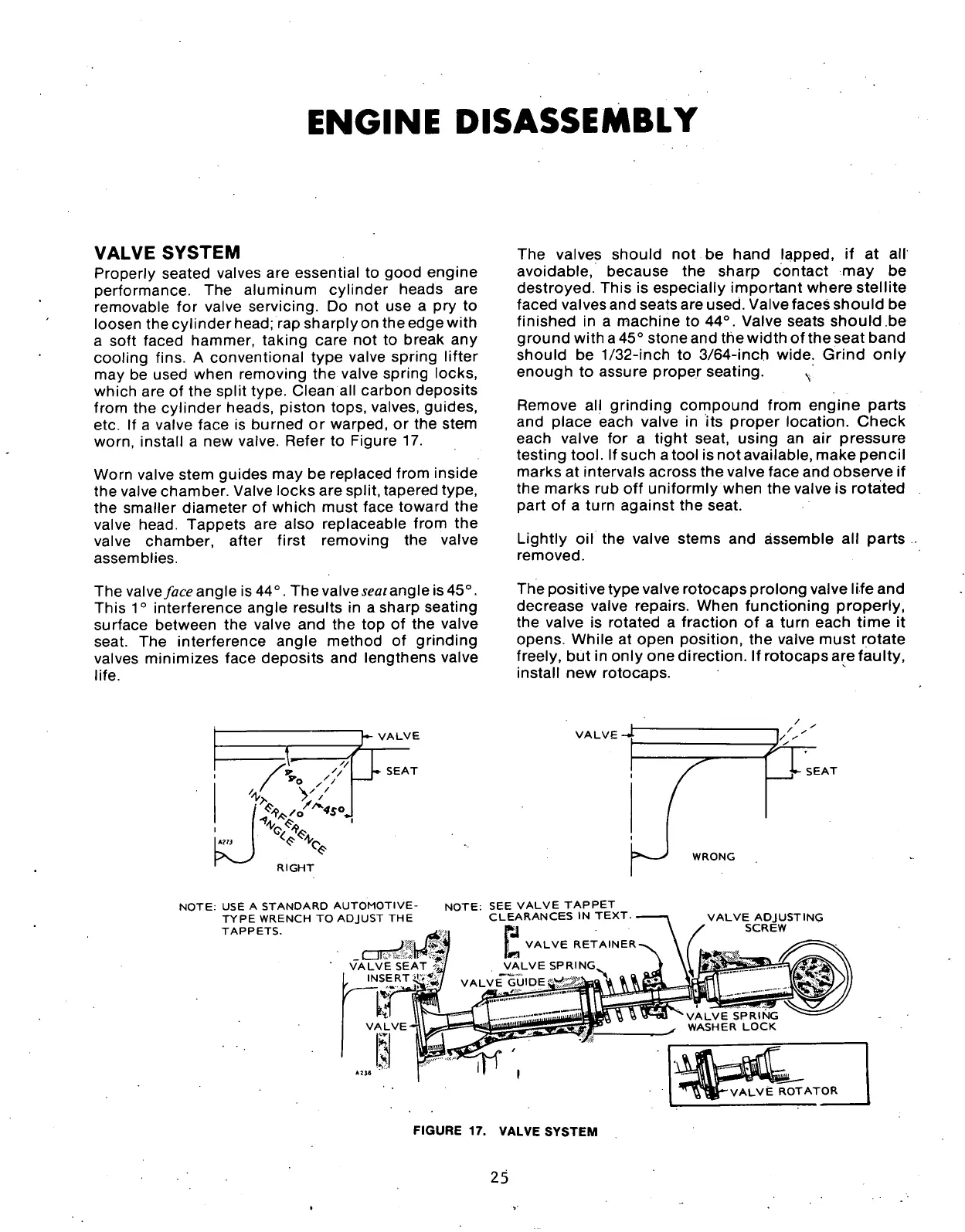

Worn valve stem guides may be replaced from inside

the valve chamber. Valve locks are split, tapered type,

the smaller diameter of which must face toward the

valve head. Tappets are also replaceable from the

valve chamber, after first removing the valve

assemblies.

The valves should not be hand lapped, if at all

avoidable, because the sharp contact may be

destroyed.

This is especially important where stellite

faced valves and seats are used. Valve faces should be

finished in a machine to 44°. Valve seats should be

ground with a 45° stone and the width ofthe seat band

should be

1/32-inch

to 3/64-inch wide. Grind only

enough to assure proper seating.

N

Remove all grinding compound from engine parts

and place each valve in its proper location. Check

each valve for a tight seat, using an air pressure

testing

tool.

If such a tool is not available, make pencil

marks at intervals across the valve face and observe if

the marks rub off uniformly when the valve is rotated

part of a turn against the seat.

Lightly oil the valve stems and assemble all parts

removed.

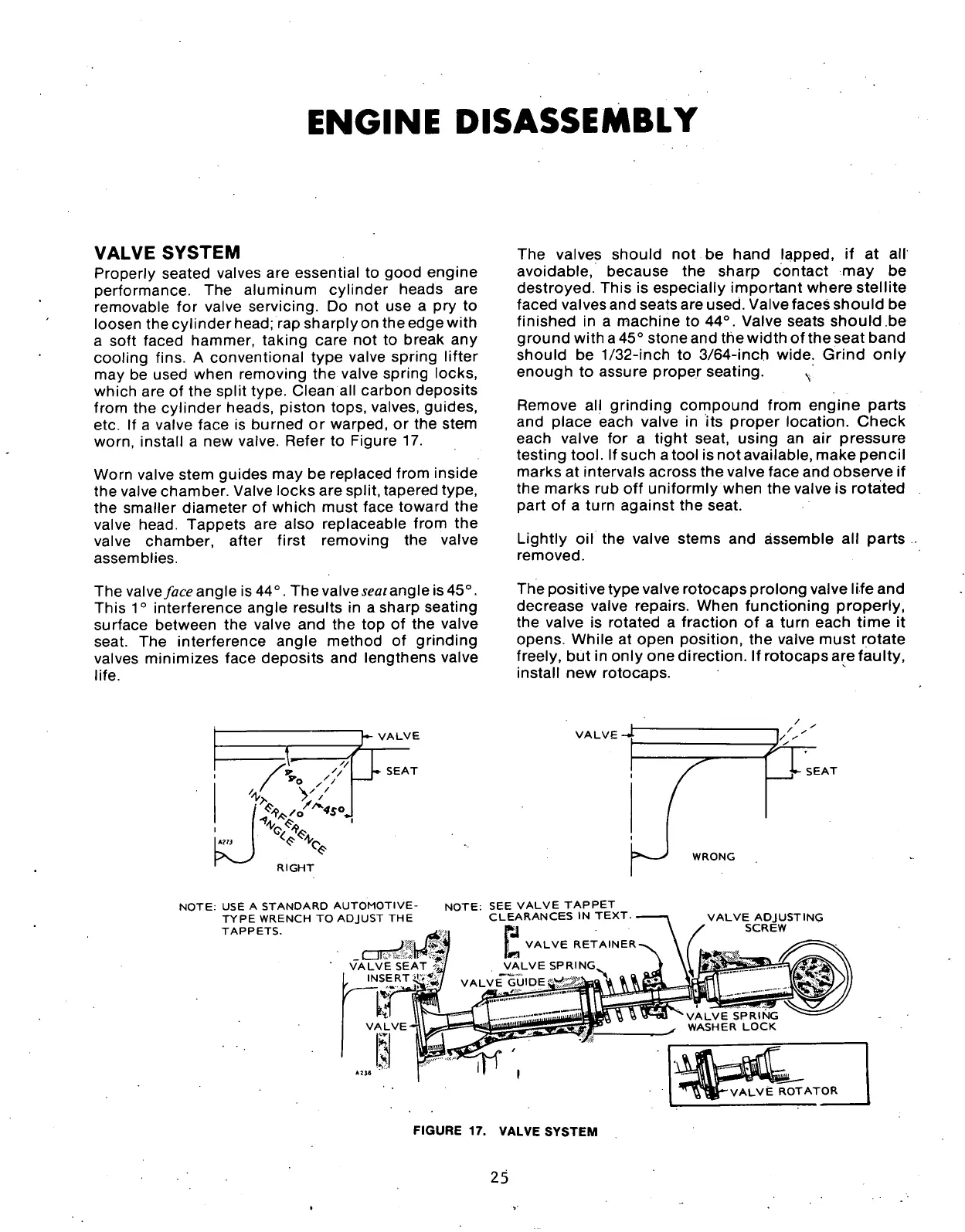

The valve face angle is 44°. The valve

seat

angle is 45°.

This 1° interference angle results in a sharp seating

surface between the valve and the top of the valve

seat. The interference angle method of grinding

valves minimizes face deposits and lengthens valve

life.

The positive type valve rotocaps prolong valve life and

decrease valve repairs. When functioning properly,

the valve is rotated a fraction of a turn each time it

opens. While at open position, the valve must rotate

freely, but in only one direction. If rotocaps are faulty,

install new rotocaps.

VALVE

</ V''

RIGHT

» SEAT

VALVE-

V SEAT

WRONG

NOTE:

USE A STANDARD AUTOMOTIVE-

TYPE WRENCH TO ADJUST THE

TAPPETS.

NOTE:

SEE VALVE TAPPET

CLEARANCES IN TEXT.

VALVE RETAINER-

VALVE SPRING^

VALVE ADJUSTING

SCREW

FIGURE 17. VALVE SYSTEM

25

Loading...

Loading...