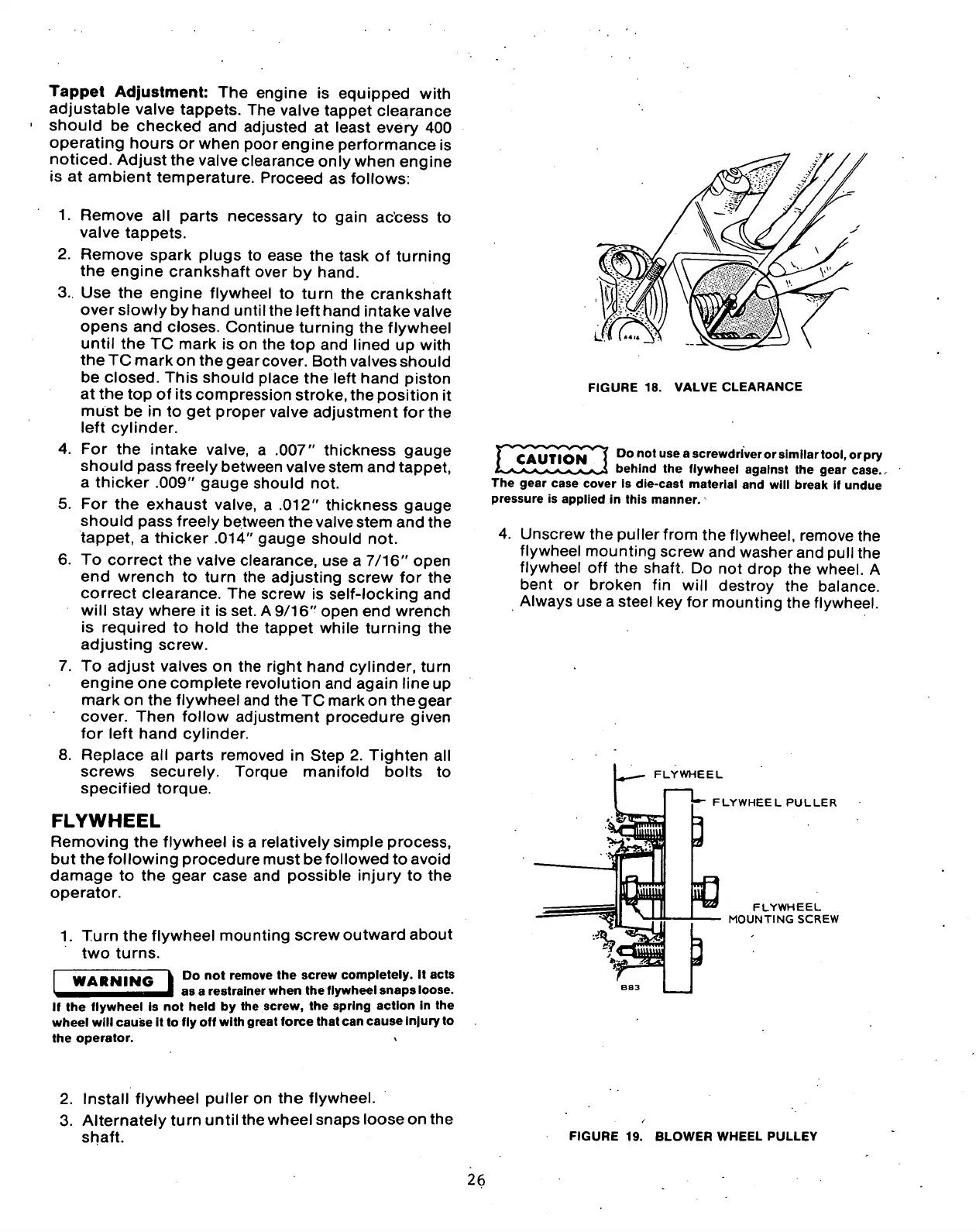

Tappet Adjustment: The engine is equipped with

adjustable valve tappets. The valve tappet clearance

should be checked and adjusted at least every 400

operating hours or when poor engine performance is

noticed.

Adjust the valve clearance only when engine

is at ambient temperature. Proceed as follows:

1.

Remove all parts necessary to gain access to

valve tappets.

2.

Remove spark plugs to ease the task of turning

the engine crankshaft over by hand.

3. Use the engine flywheel to turn the crankshaft

over slowly by hand until the left hand intake valve

opens and closes. Continue turning the flywheel

until the TC mark is on the top and lined up with

the TC mark on the gear cover. Both valves should

be closed. This should place the left hand piston

at the top of its compression stroke, the position it

must be in to get proper valve adjustment forthe

left cylinder.

4.

For the intake valve, a .007" thickness gauge

should pass freely between valve stem and tappet,

a thicker .009" gauge should not.

5. For the exhaust valve, a .012" thickness gauge

should pass freely between the valve stem and the

tappet, a thicker .014" gauge should not.

6. To correct the valve clearance, use a 7/16" open

end wrench to turn the adjusting screw for the

correct clearance. The screw is self-locking and

will stay where it is set. A 9/16" open end wrench

is required to hold the tappet while turning the

adjusting screw.

7. To adjust valves on the right hand cylinder, turn

engine one complete revolution and again line up

mark on the flywheel and the TC mark on the gear

cover. Then follow adjustment procedure given

for left hand cylinder.

8. Replace all parts removed in Step 2. Tighten all

screws securely. Torque manifold bolts to

specified torque.

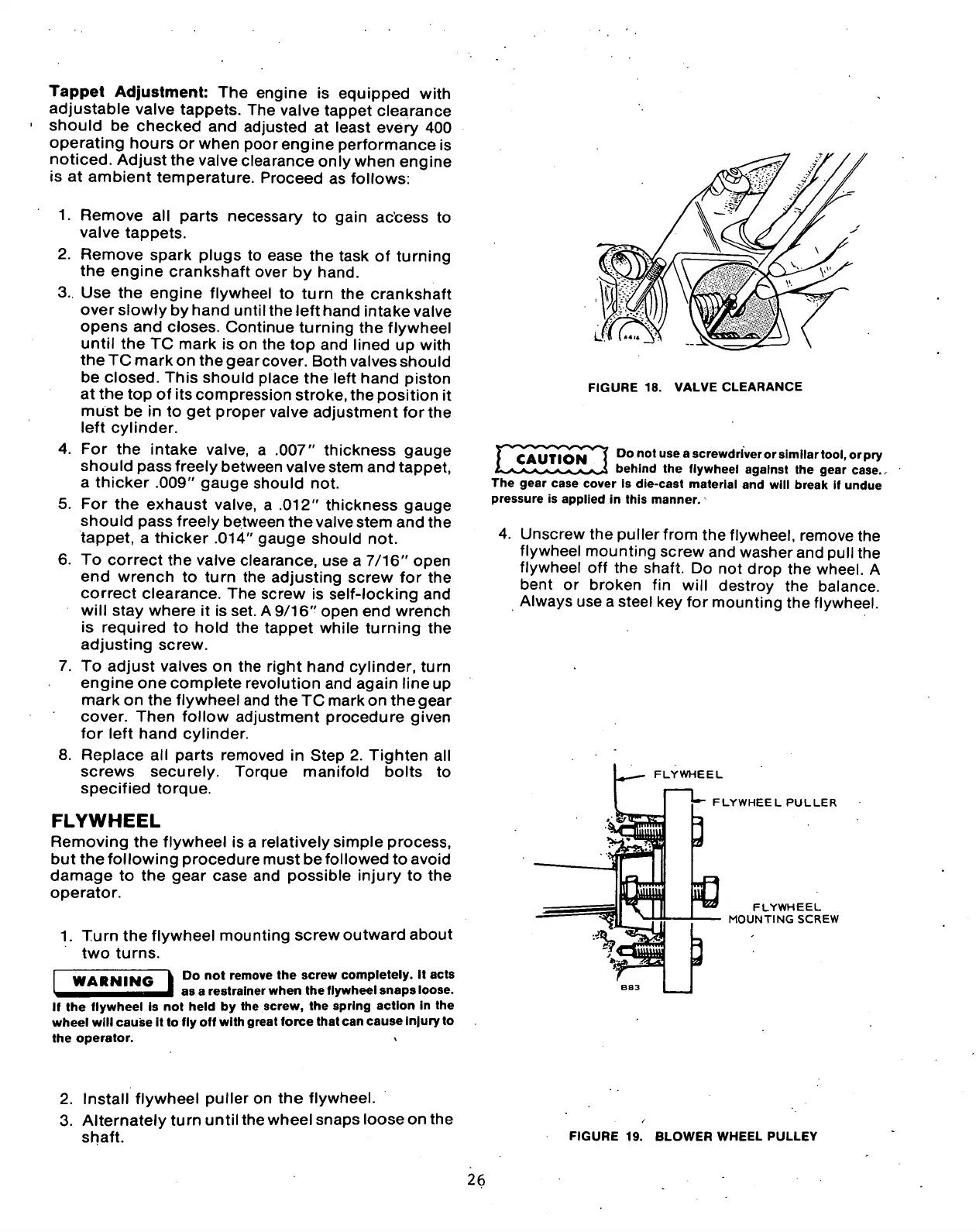

FLYWHEEL

Removing the flywheel isa relatively simple process,

but thefollowing procedure must be followed to avoid

damage to the gear case and possible injury to the

operator.

1.

Turn the flywheel mounting screw outward about

two turns.

WARNING

Do not remove the screw completely. It acts

as a restrainer when the flywheel snaps loose.

If the flywheel is not held by the screw, the spring action in the

wheel will cause it to fly off with great force that can cause injury to

the operator.

FIGURE 18. VALVE CLEARANCE

CAUTION

fc

w—w-*. /'w'S. S\ ^^J

Do not use a screwdriver or similar

tool,

or pry

behind the flywheel against the gear case.

•

The gear case cover is die-cast material and will break if undue

pressure is applied in this manner.

4.

Unscrew the puller from the flywheel, remove the

flywheel mounting screw and washer and pull the

flywheel off the shaft. Do not drop the wheel. A

bent or broken fin will destroy the balance.

Always use a steel key for mounting the flywheel.

FLYWHEEL

FLYWHEEL PULLER

FLYWHEEL

MOUNTING SCREW

2.

Install flywheel puller on the flywheel.

3. Alternately turn until the wheel snaps loose on the

shaft.

FIGURE 19. BLOWER WHEEL PULLEY

26

Loading...

Loading...