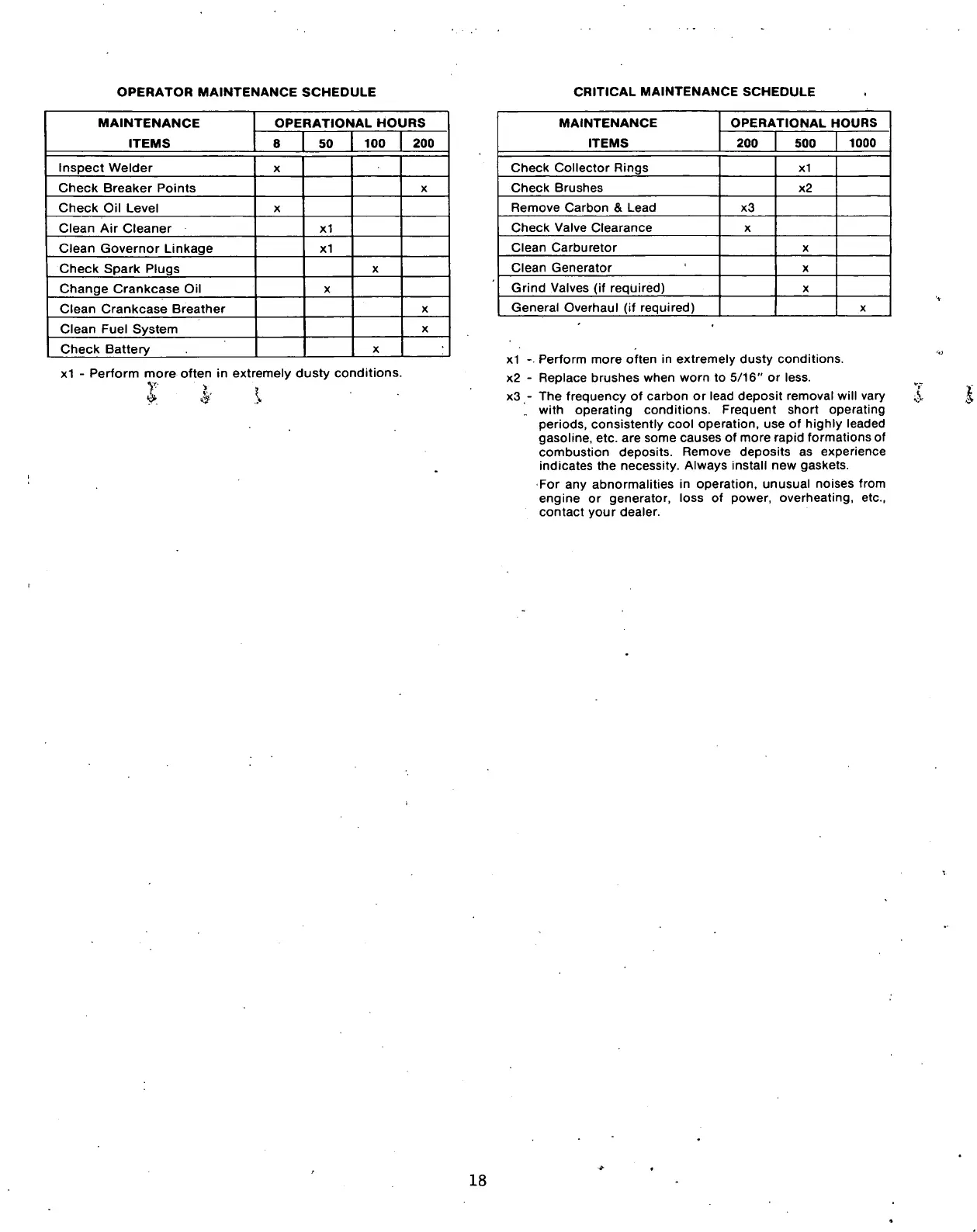

OPERATOR

MAINTENANCE

SCHEDULE

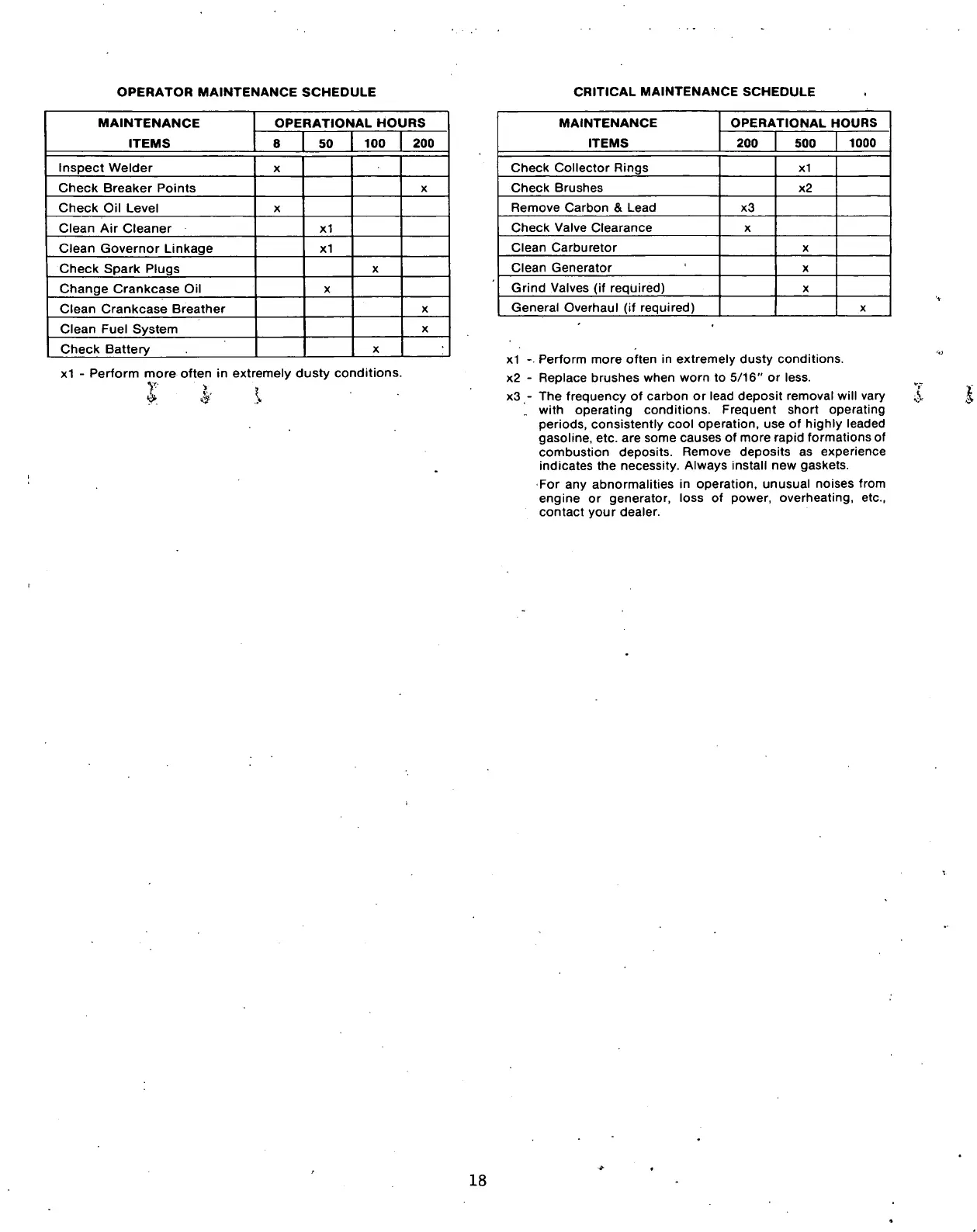

CRITICAL

MAINTENANCE

SCHEDULE

MAINTENANCE

ITEMS

OPERATIONAL

HOURS

MAINTENANCE

ITEMS

8 50

100 200

Inspect Welder X

Check Breaker Points

X

Check Oil Level

X

Clean Air Cleaner xl

Clean Governor Linkage xl

Check Spark Plugs

X

Change Crankcase Oil

X

Clean Crankcase Breather

X

Clean Fuel System

X

Check Battery

X

xl - Perform more often in extremely dusty conditions.

MAINTENANCE

ITEMS

OPERATIONAL

HOURS

MAINTENANCE

ITEMS

200 500

1000

Check Collector Rings

xl

Check Brushes

x2

Remove Carbon & Lead

x3

Check Valve Clearance X

Clean Carburetor X

Clean Generator X

Grind Valves (if required) X

General Overhaul (if required) X

xl - Perform more often in extremely dusty conditions.

x2 - Replace brushes when worn to 5/16" or less.

x3 - The frequency of carbon or lead deposit removal will vary

with operating conditions. Frequent short operating

periods, consistently cool operation, use of highly leaded

gasoline, etc. are some causes of more rapid formations of

combustion deposits. Remove deposits as experience

indicates the necessity. Always install new gaskets.

For any abnormalities in operation, unusual noises from

engine or generator, loss of power, overheating, etc.,

contact your dealer.

18

Loading...

Loading...