3. Rotate the crank about 30 degrees from bottom

dead center and reinstall the bearing cap; tighten

the bolts to the torque specified in Assembly

Torques. Do not turn the crankshaft.

4.

Remove the bearing cap. Leave the flattened

Plastigauge on the part to which it has adhered

and compare the widest point with the

graduations on the Plastigauge envelope to

determine bearing clearance/.

OIL

SEALS

(Figure 36)

The bearing plate must be removed to replace the oil

seal.

Drive the oil seal out from the inside.

Before installing the seals, fill the space between lips

with a multi-purpose grease. This will improve

seal-

ing.-

When installing the gear cover oil

seal,

tap the seal

inward until it is 31/32" from the mounting face ofthe

cover.

When installing the bearing plate oil

seal,

tap the seal

into the bearing plate bore to bottom against the

shoulder in the plate bore. Use a seal expander or

place a piece of shim stock around the end of the

crankshaft, when replacing the bearing plate to avoid

damaging the

seal.

Remove the shim stock as soon as

the plate is in place.

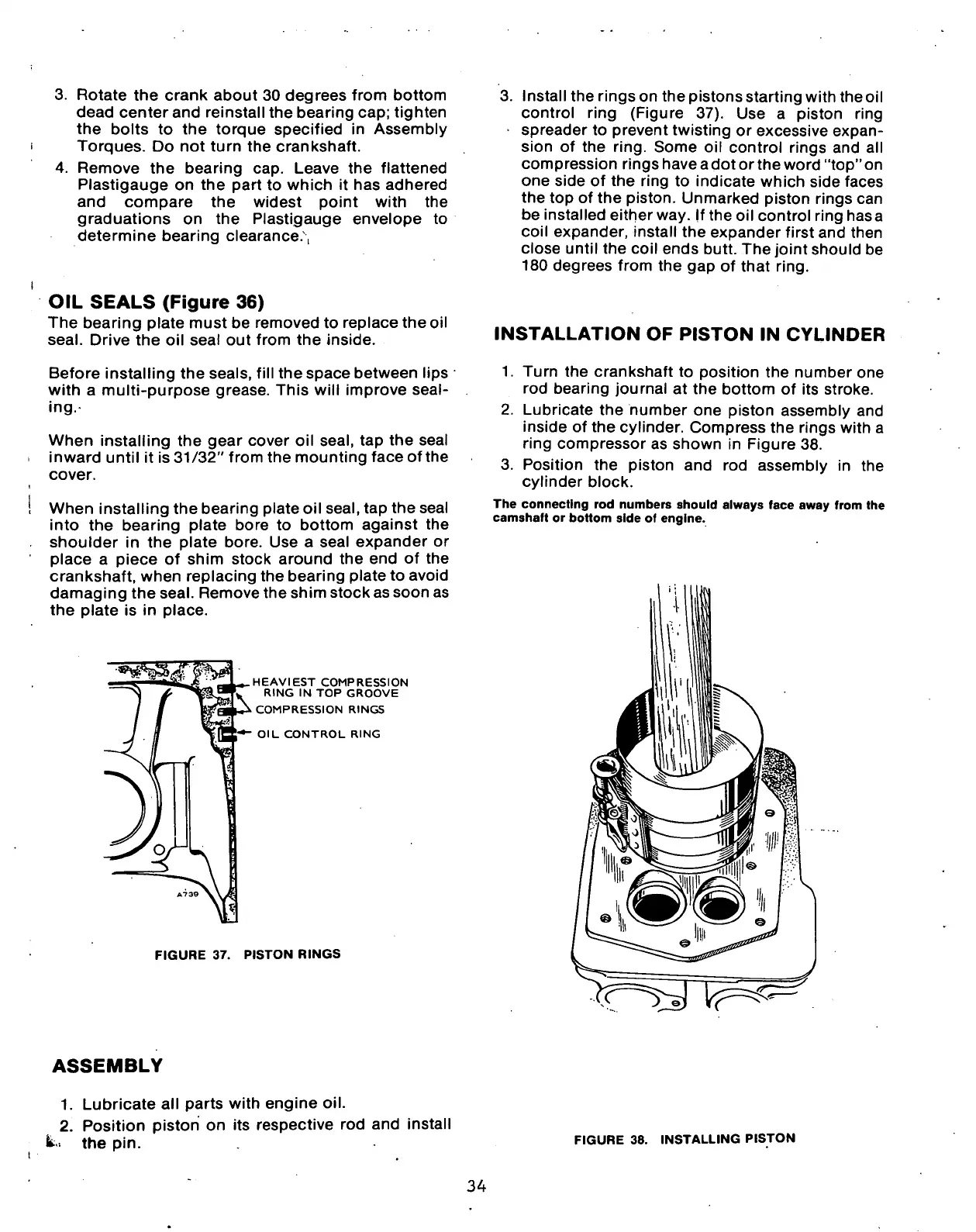

HEAVIEST COMPRESSION

RING IN TOP GROOVE

COMPRESSION RINGS

OIL CONTROL RING

FIGURE 37. PISTON RINGS

3. Install the rings on the pistons starting with the oil

control ring (Figure 37). Use a piston ring

spreader to prevent twisting or excessive expan-

sion of the

ring.

Some oil control rings and all

compression rings have a dot or the word "top" on

one side of the ring to indicate which side faces

the top of the piston. Unmarked piston rings can

be installed either way. |f the oil control ring hasa

coil expander, install the expander first and then

close until the coil ends butt. The joint should be

180 degrees from the gap of that

ring.

INSTALLATION

OF PISTON IN

CYLINDER

1.

Turn the crankshaft to position the number one

rod bearing joumal at the bottom of its stroke.

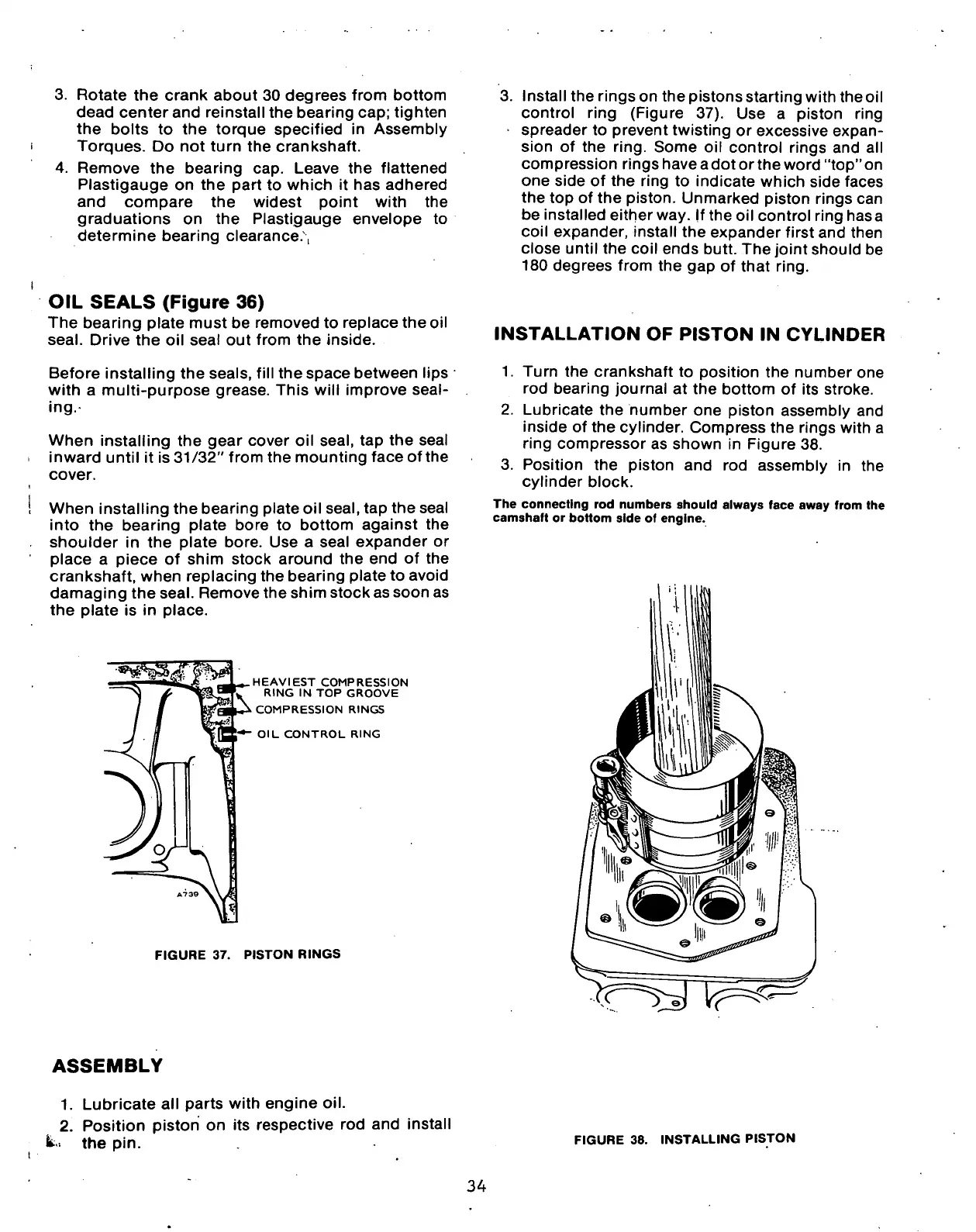

2.

Lubricate the humber one piston assembly and

inside of the cylinder. Compress the rings with a

ring compressor as shown in Figure 38.

3. Position the piston and rod assembly in the

cylinder block.

The connecting rod numbers should always face away from the

camshaft or bottom side of engine.

ASSEMBLY

1.

Lubricate all parts with engine oil.

2.

Position piston on its respective rod and install

fe- the pin.

FIGURE 38. INSTALLING PISTON

34

Loading...

Loading...