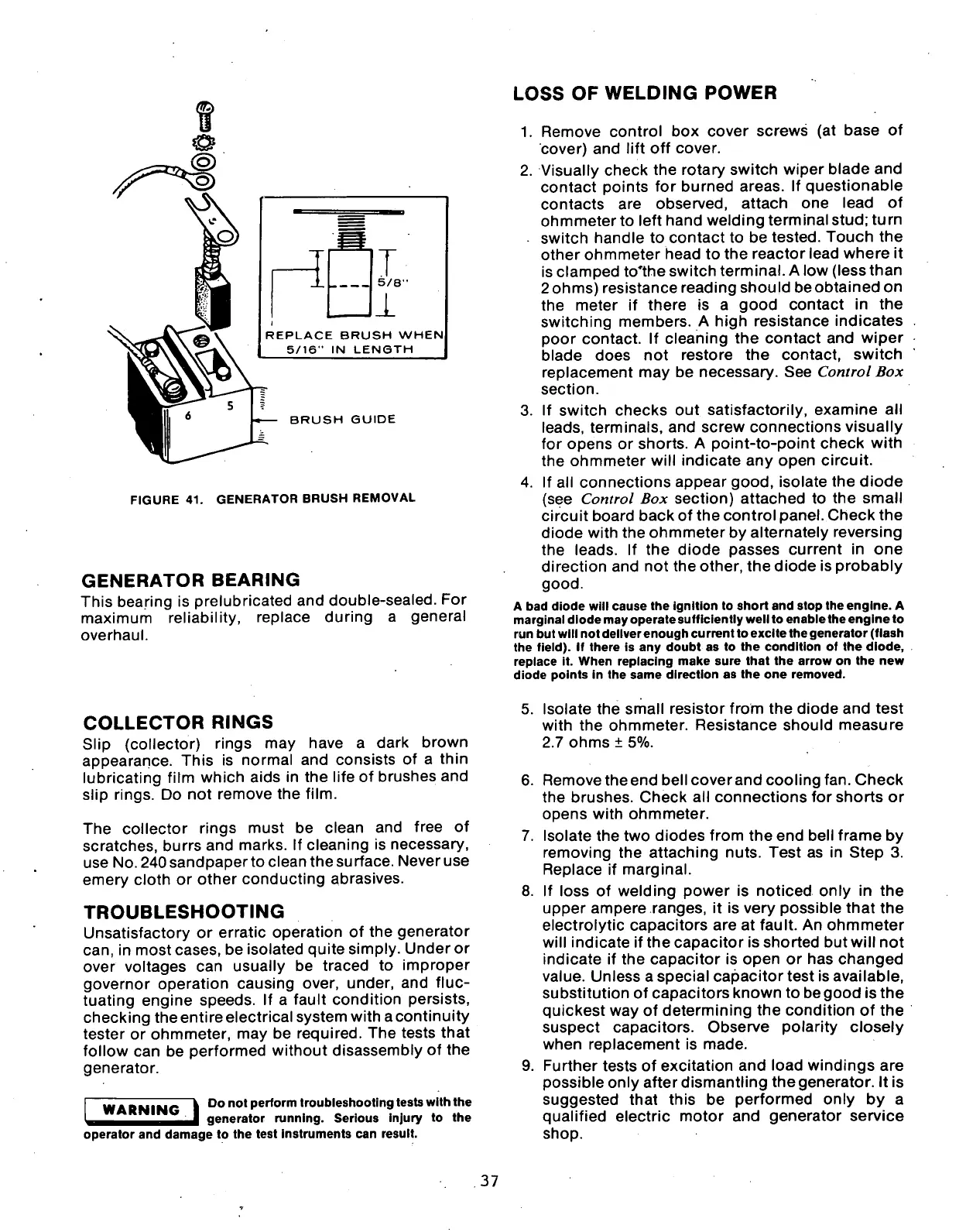

5/8"

REPLACE BRUSH WHEN

5/16" IN LENGTH

BRUSH GUIDE

FIGURE 41. GENERATOR BRUSH REMOVAL

GENERATOR

BEARING

This bearing is prelubricated and double-sealed. For

maximum reliability, replace during a general

overhaul.

LOSS

OF WELDING

POWER

1.

Remove control box cover screws (at base of

cover) and lift off cover.

2.

Visually check the rotary switch wiper blade and

contact points for burned areas. If questionable

contacts are observed, attach one lead of

ohmmeter to left hand welding terminal

stud;

turn

switch handle to contact to be tested. Touch the

other ohmmeter head to the reactor lead where it

is clamped to'the switch terminal. A low (less than

2ohms) resistance reading should beobtained on

the meter if there is a good contact in the

switching members. A high resistance indicates

poor contact. If cleaning the contact and wiper

blade does not restore the contact, switch

replacement may be necessary. See Control Box

section.

3. If switch checks out satisfactorily, examine all

leads,

terminals, and screw connections visually

for opens or shorts. A point-to-point check with

the ohmmeter will indicate any open circuit.

4.

If all connections appear good, isolate the diode

(see Control Box section) attached to the small

circuit board back of the control panel. Check the

diode with the ohmmeter by altemately reversing

the leads. If the diode passes current in one

direction and not the other, the diode is probably

good.

A bad diode will cause the ignition to short and stop the engine. A

marginal diode may operate sufficiently well to enable the engine to

run but will not deliver enough current to excite the generator (flash

the field). If there is any doubt as to the condition of the diode,

replace it. When replacing make sure that the arrow on the new

diode points in the same direction as the one removed.

COLLECTOR

RINGS

Slip (collector) rings may have a dark brown

appearance. This is normal and consists of a thin

lubricating film which aids in the life of brushes and

slip rings. Do not remove the

film.

The collector rings must be clean and free of

scratches, burrs and marks. If cleaning is necessary,

use No. 240 sandpaper to clean the surface. Never use

emery cloth or other conducting abrasives.

TROUBLESHOOTING

Unsatisfactory or erratic operation of the generator

can,

in most cases, be isolated quite simply. Under or

over voltages can usually be traced to improper

governor operation causing over, under, and fluc-

tuating engine speeds. If a fault condition persists,

checking the entire electrical system with a continuity

tester or ohmmeter, may be required. The tests that

follow can be performed without disassembly of the

generator.

WARNING

Do not perform troubleshooting tests with the

generator running. Serious injury to the

5. Isolate the small resistor from the diode and test

with the ohmmeter. Resistance should measure

2.7 ohms ± 5%.

6. Remove the end bell coverand cooling fan. Check

the brushes. Check all connections for shorts or

opens with ohmmeter.

7.

8.

9.

operator and damage to the test instruments can result.

Isolate the two diodes from the end bell frame by

removing the attaching nuts. Test as in Step 3.

Replace if marginal.

If loss of welding power is noticed only in the

upper ampere ranges, it is very possible that the

electrolytic capacitors are at fault. An ohmmeter

will indicate if the capacitor is shorted but will not

indicate if the capacitor is open or has changed

value.

Unless a special capacitor test is available,

substitution of capacitors known to be good is the

quickest way of determining the condition of the

suspect capacitors. Observe polarity closely

when replacement is made.

Further tests of excitation and load windings are

possible only after dismantling the generator. It is

suggested that this be performed only by a

qualified electric motor and generator service

shop.

37

Loading...

Loading...