ADJUSTMENTS

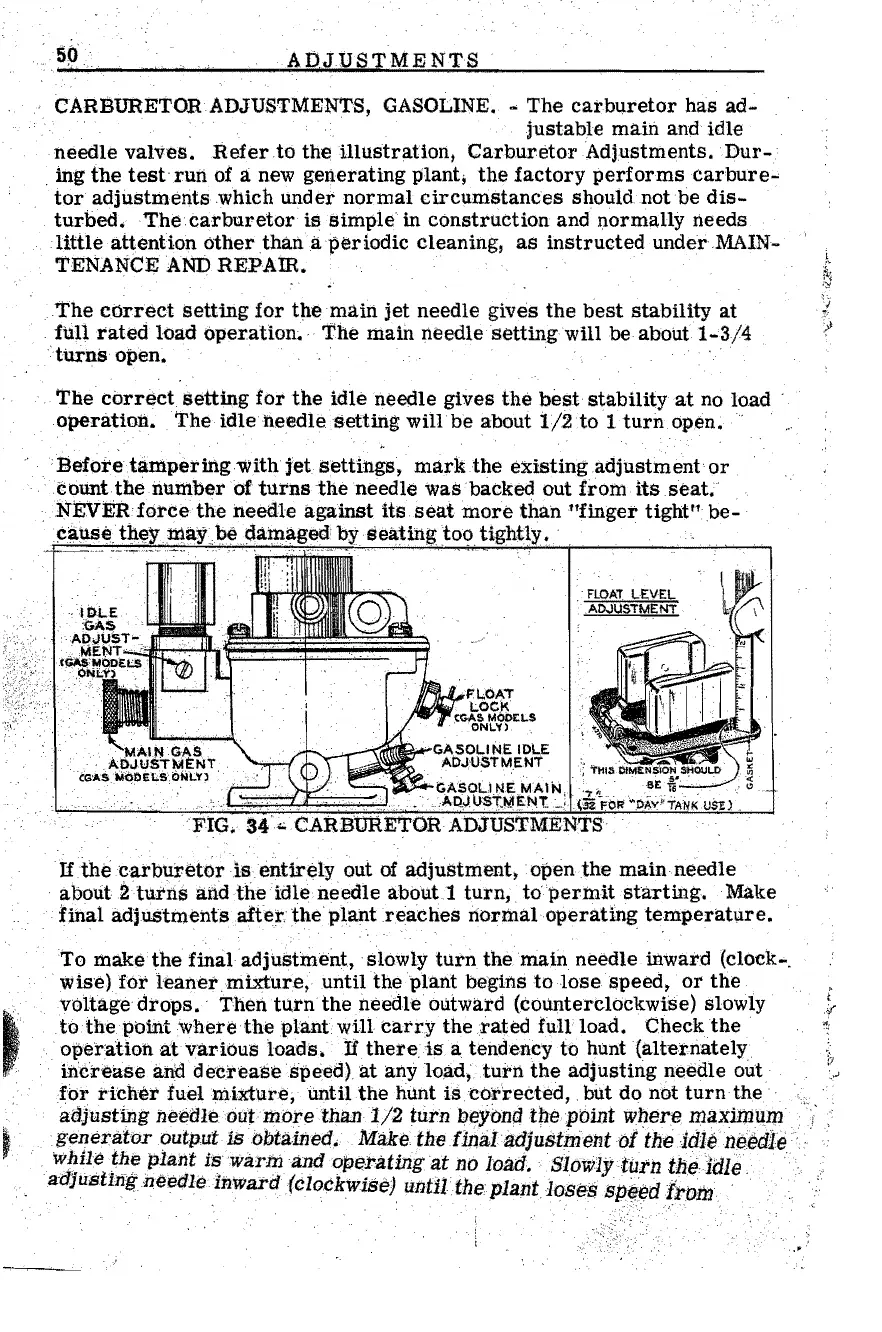

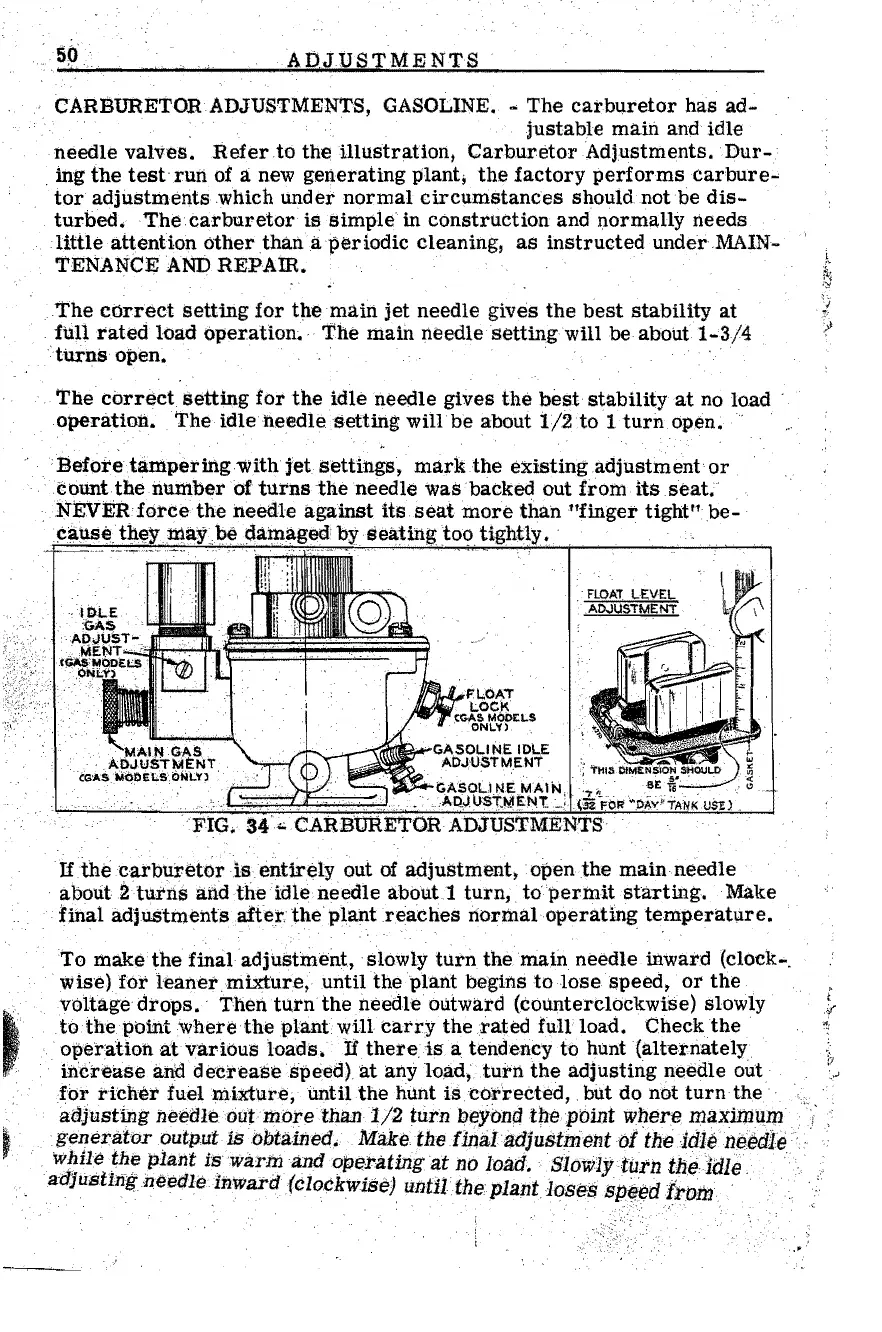

GARBURETORADJUST:MENTS,

GASOLINE

...

The carbl!.retor has

ad-

justable main and idle

needle valVes.

Refer

to

the illustration,

Carburetor

Adjustments.

Dur-

. ing the

test

run

of

a.

new

generating plant; the factory

performs

carbure-

tor

adjustments which under normal

circumstances

should not be

dis-

turbed.Thecarburetor

is

simple

in construction and normally needs

little attention other

than

aperiodic

cleaning,

as

instructed under MAIN-

TENANCE

AND

REPAlR.

.

The

c.orrect setting

for

themairi

jet

needle gives the

best

stability

at

full

rated

load

()peration~·

The main needle setting

will

be

about

1-3/4

..

turns

open. .

f

(

The

correct

setting

for

the idle needle gives the

best

stability

at

no

load

operation. The idle needle setting will be about

1/2to

1

turn

open.

Before

tampetingwith

jet

settitlgs,

mark

the existing adjustment

or

countthe

number

of

turns

the

needle

WaS

backed out from

its

seat.

:NEVERfOI'ce the needle against its

seat

more

than fffinger tight

l1

be-

too

't1o't'I'tl!u

If

the

carburetor

IS entirely out of adjustment, open

the

main needle

. about

2turns and the idle needle about.1 turn,

to

permit

starting.

Make

final adjustments afte.t the

plant

reaches normal operating

temperature.

To make the

final

adjusbnei:tt, slowly

turn

the

main

needle inward (clock-.

Wise) for

leanetmixture,

until the plant begins

to

lose

speed,

or

the

voltage eh-ops.· Then

turn

the needle outward (counterclockwise) slowly

to

the

pomt

where

the

plant

will

carry

the rated

lull

load.

Checkthe

operation

at

various loads.

It

there.

is

a teildency tu hunt (alternately

mcrease

and

decteasespeed)

at

any luad; turn the adjusting needle out

for

richer

fuel mixture, \illtilthe hunt

iseorrecled,.

but do not

turn

the

adjusting

heedleoutmoI'e than

1/2

turn

beyonq

t:hepoint where

maximum

generator

outp.u.t

ISobtaified. Make the

flnaladjustmentofthe

idle

needJe

w~ile!hf:plantis.wal"'i.na.nd

operating

at

no

load. SlowlY

lotn

theld1e

..

a:dJustlngneedle.znward(clockwise) untll.the. plant loses

SP~d

from

.

.'

Loading...

Loading...