SPARK PLUG

A

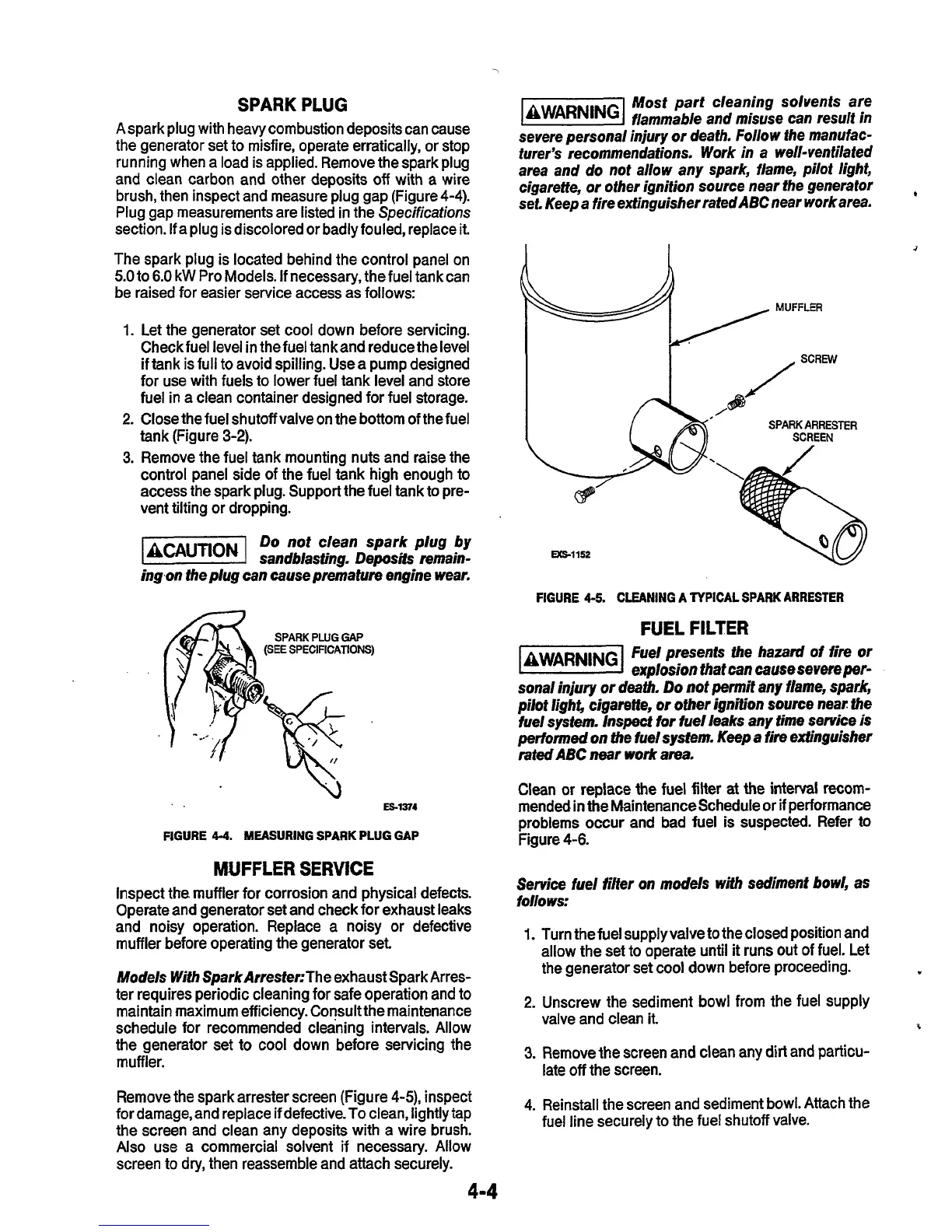

spark plug with heavy combustion deposits can cause

the generator set to misfire, operate erratically, or stop

running when a load is applied. Remove the spark plug

and clean carbon and other deposits

off

with a wire

brush, then inspect and measure plug gap (Figure

4-4).

Plug gap measurements are listed in the Specifications

section.

If

a plug is discolored or badly fouled, replace it.

The spark plug is located behind the control panel on

5.0

to

6.0

kW Pro Models. If necessary, the fuel tank can

be raised for easier service access as follows:

Let the generator set cool down before servicing.

Checkfuel level in thefuel tankand reduce thelevel

if

tank is full to avoid spilling. Use

a

pump designed

for use with fuels to lower fuel tank level and store

fuel in a clean container designed for fuel storage.

Closethe fuel shutoff valve on the bottom of the fuel

tank (Figure

3-2).

Remove the fuel tank mounting nuts and raise the

control panel side of the fuel tank high enough to

access the spark plug. Support the fuel tank to pre-

vent tilting or dropping.

Do

not clean spark plug by

sandblasting. Deposits remain-

ing,on the plug can cause premature engine wear.

SPARK

PWG

GAP

(SEE

SPECIFICATIONS)

ES-1374

AGURE

4-4.

MEASURING SPARK

PLUG

GAP

MUFFLER

SERVICE

Inspect the muff ter for corrosion and physical defects.

Operate and generator set and check for exhaust leaks

and noisy operation. Replace a noisy or defective

muffler before operating the generator set

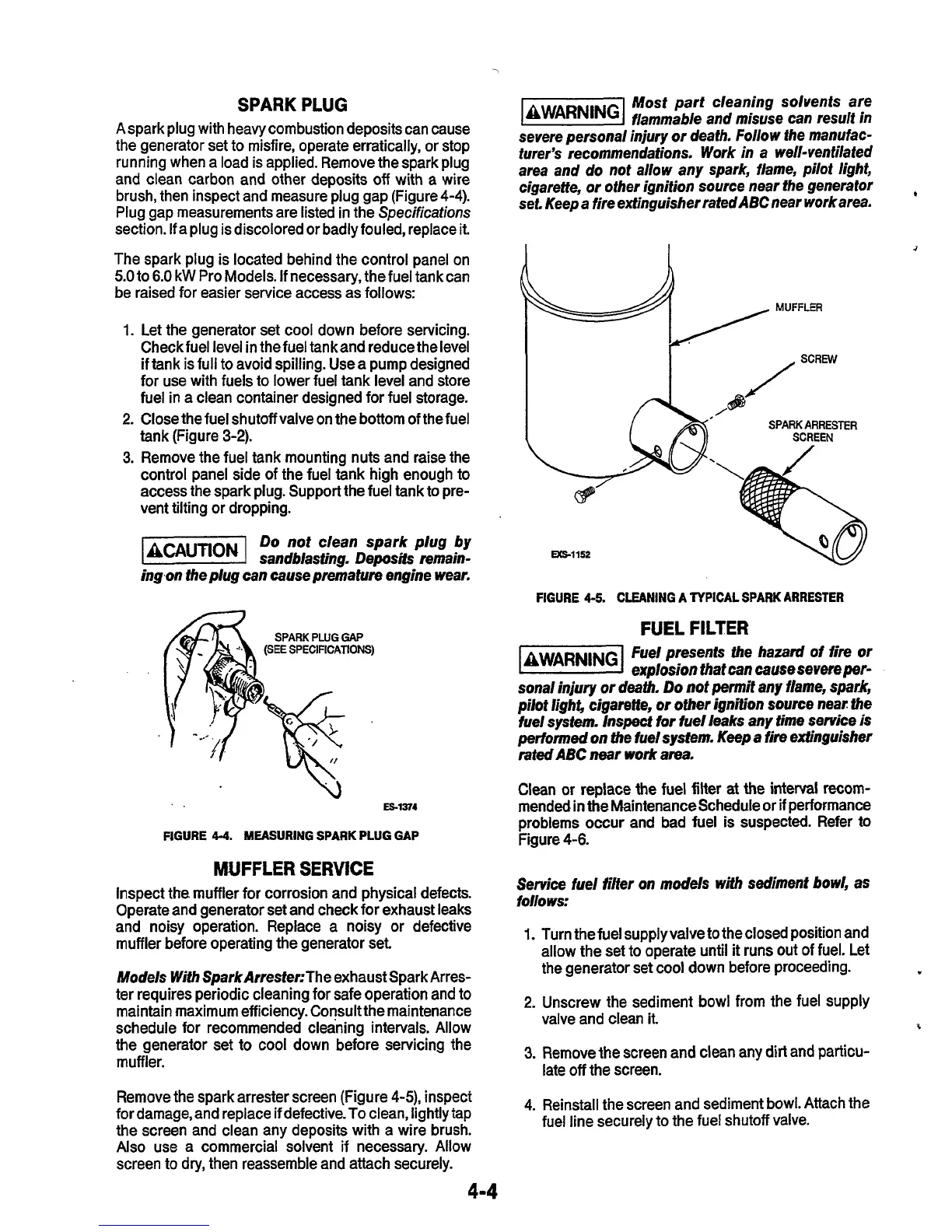

Models With SparkArrester:The

exhaust Spark Arres-

ter requires periodic cleaning for safe operation and to

maintain maximum efficiency. Consult the maintenance

schedule for recommended cleaning intervals. Allow

the generator set to cool down before servicing the

muffler.

Remove the spark arrester screen (Figure

44,

inspect

for damage, and replace

if

defective.To clean, lightly tap

the screen and clean any deposits with a wire brush.

Also

use a commercial solvent if necessary. Allow

screen to dry, then reassemble and attach securely.

4-4

Most part cleaning solvents are

flammable and misuse can result in

severe personal injury

or

death. Follow the manufac-

turer’s recommendations. Work in a well-ventilated

area and do not allow any spark, flame, pilot light,

cigarette,

or

other ignition source near the generator

set. Keep a fire extinguisherratedABC near workarea.

,

SPARK

ARRESTER

SCREEN

Exs-1152

FIGURE

4-5.

CLEANING

A

TYPICAL SPARK

ARRESTER

FUEL

FILTER

1-1

Fuel

presents

the hazard of fire

or

explosion fhatcan

muse

severeper-

sonal injury

or

death

Do

not

permit any flame,

spark,

pirot

Iighb

cigarette,

or

other ignition

source

near: the

iuel system.

kspeci

for

iuel leaks any time service is

performed

on

the iuel system. Keep a

fire

extinguisher

rated

ABC

near

work

area.

Clean or replace the fuel filter

at

the

interval

recom-

mended

in

the Maintenance Schedule or if performance

problems occur and bad fuel

is

suspected. Refer to

Figure

4-6.

Service fuel tilter on models

with

sediment bowl,

as

follows:

1.

2.

3.

4.

Turn the fuel supply valve to the closed position and

allow the set to operate until it runs out of fuel. Let

the generator set cool down before proceeding.

Unscrew the sediment bowl from the fuel supply

valve and clean

it.

4

Remove the screen and clean any dirt and particu-

late

off

the screen.

Reinstall the screen and sediment bowl. Attach the

fuel line securely to the fuel shutoff valve.

Loading...

Loading...